What you’ll pay in Los Angeles for furnace repairs depends on many factors. Here’s a breakdown of what can go wrong and the cost to fix those issues.

Your home’s energy efficiency starts with your HVAC system

Energy loss in ductwork occurs due to damage, poor insulation, and faulty installation.

Sheet metal is the most durable and efficient material, but it’s also the most costly.

Flexible and fiberboard ducts have insulation, but the material needs more maintenance.

Proper installation and sealing are the biggest factors in ductwork’s energy efficiency.

Ductwork’s role in an energy-efficient home often goes unnoticed, but the type of ductwork material you choose can significantly impact the efficiency of your HVAC system. But what is the most efficient ductwork to ensure you save as much energy as possible? Let’s explore the world of ductwork and discuss what makes it efficient or inefficient.

Whether you're building a new home, renovating, or simply looking to upgrade your HVAC system, understanding the best ductwork material for your home is essential.

Before we dive into ductwork efficiency, let's start with the basics. The term “ductwork” refers to the system of pathways or channels that carry air from your HVAC unit to the air vents in various rooms in your home and back again. Air ducts are essentially the circulatory system of your HVAC setup, ensuring that conditioned air reaches every nook and cranny.

While it’s clear that sheet metal ducts may be the most energy-efficient ductwork due to the lower chance of damage and deterioration, each home has unique needs when it comes to its HVAC setup. Some homes may not be able to accommodate the space needed for sheet metal ducts, for example, due to tight spaces or bends.

When it comes to efficiency, the most important factor for ductwork is that it’s properly designed and installed. Ductwork that is well-sealed, properly insulated, and configured to minimize bends and turns will create the most efficient setup.

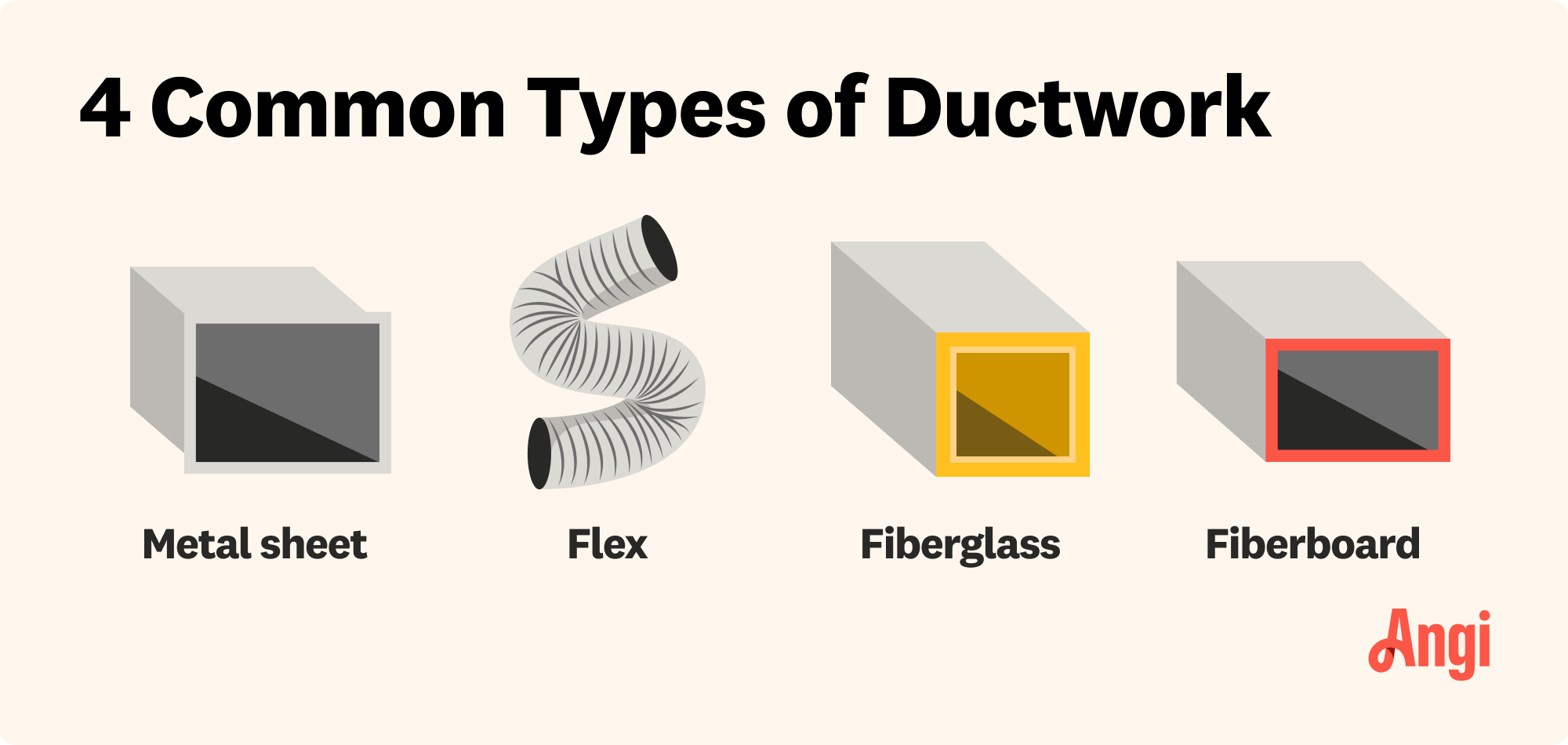

The energy efficiency of your HVAC system also depends on the type of ductwork used. Let's explore some common material options.

Sheet metal ductwork, often considered the most energy-efficient ductwork, is a type of duct system made from durable materials like galvanized steel or aluminum. Its benefits include exceptional durability, resistance to damage from pests, and smooth surfaces that reduce air resistance, enhancing airflow efficiency. However, proper insulation is needed to prevent heat loss or gain, which can be a drawback if not addressed.

Constructed from fiberglass-reinforced materials, fiberglass ductwork gets its energy efficiency benefits from good insulation properties, helping maintain desired temperatures. However, the material's potential to deteriorate over time can be a downfall. Regular maintenance is crucial for preserving energy efficiency, making it important to weigh the advantages of insulation against the need for durability when opting for fiberglass ductwork.

Fiberboard ductwork is made from compressed fiberglass or wood fibers and is known for its affordability. Its benefits for energy efficiency come from the option to easily insulate the ductwork, improving thermal performance. However, fiberboard is less durable than some other duct materials, and proper maintenance is essential to prevent wear and tear that could impact energy efficiency. Therefore, while cost-effective, consider the fact that fiberboard ductwork may need to be replaced sooner to ensure optimal energy savings.

Flexible ductwork is a versatile duct material made of a flexible outer layer and an inner insulation layer. It’s known for being affordable, easy to install, and a suitable option for tight spaces. However, the flexible nature of this type of ductwork can lead to restrictions and bends that reduce airflow efficiency, potentially impacting energy efficiency. The material is also more prone to tears and other damage, leading to leakage. Careful installation is essential to maximize energy savings when using flexible ductwork.

One of the biggest problems with ductwork is that heated or cooled air can often diminish as the air travels the length of the ductwork and into your home. This means that your HVAC unit will have to work harder to maintain the desired temperature in your home, leading more quickly to the cost of HVAC replacement or frequent repairs.

Energy efficiency concerns arise due to various factors in your HVAC system, each contributing to energy loss in ductwork.

Quality ductwork will increase the efficiency of your HVAC, sometimes by 20% to 30%. This is because there is reduced air leakage due to better insulation and more optimized airflow. This means your HVAC doesn't have to work as hard to keep the desired temperature, so it uses less energy.

One common issue is leaks caused by damaged ductwork materials. Over time, wear and tear can lead to small holes or cracks in the ducts, allowing heated or conditioned air to escape into unconditioned spaces like attics or crawl spaces. These issues are why durable materials are a must for ductwork.

Another culprit for inefficiency is improper installation. If ducts are not installed correctly, they may have kinks, bends, or misalignments that obstruct airflow, allow air to escape, or otherwise reduce efficiency.

Sealing is crucial in ductwork, especially around grilles and registers. These are openings that control the flow of conditioned air into rooms, allowing for temperature regulation and air distribution within your home. Poor sealing can lead to air leakage, which forces your HVAC system to work harder to maintain the desired temperature.

Inefficient ductwork configuration can also lead to energy waste. Ducts that are too long, have too many bends, or are the wrong size can result in decreased airflow and increased energy consumption.

Installing new ductwork costs anywhere between $1,400 and $9,000 for the whole home or $1 to $13 per linear foot plus labor costs. The prices vary based on the material, location, and home size. Flexible non-insulated ducts are much cheaper than sheet metal, for example. Similarly, it is less expensive to install ducts in readily accessible spaces, like basements, than in cramped areas like crawl spaces.

The condition of the installation area can also impact the cost. Air duct cleaning costs $150 to $800. You may also need to pay an extra $200 to $700 for mold or asbestos testing. If the tests are positive, mold remediation can add up to $7,000 to the project cost, while asbestos removal costs an average of $2,200.

While DIY projects can be rewarding and save you some cash, installing ductwork is best left to professionals. A local duct installer has the knowledge and experience needed to design and install duct systems that are finely tuned for maximum efficiency. They can ensure compliance with local building codes and regulations, guaranteeing a safe and reliable installation.

Professionals also have access to specialized equipment that ensures precision and quality. The peace of mind that comes with warranties and guarantees is another compelling reason to opt for professional installation.

From average costs to expert advice, get all the answers you need to get your job done.

What you’ll pay in Los Angeles for furnace repairs depends on many factors. Here’s a breakdown of what can go wrong and the cost to fix those issues.

The average boiler installation cost depends on size, system type, and other factors. Keep reading to learn the cost of a new boiler in Los Angeles, CA.

Discover the factors influencing air duct replacement costs in Los Angeles, CA. Learn how to save money and make an informed decision for your home's comfort.

Explore the most common HVAC duct types, from flexible to sheet metal to fiberglass, and learn about their pros and cons.

There are a few different types of refrigerant for AC systems, but some contain environmental hazards. Learn about the five main types of refrigerant.

Even when you're sweating up a storm on a hot day, your AC should keep its cool. Here's what to do when condensation on your AC signals larger problems.