Furnace cleaning is an essential annual chore to keep your home safe. Find out common furnace cleaning costs by type and size of furnace with this guide.

Using flexible ducts could be a huge flex, but you should weigh the pros and cons

Flexible ducts consist of a coiled metal wire and a flexible plastic material.

In comparison to traditional ductwork, they’re cost-effective, easier to install, and aren’t as noisy.

Flex ductwork is prone to issues and has a shorter lifespan.

Using flexible air ducts for HVAC systems has become a popular alternative to metal air ducts because they’re easier and less expensive to install. Still, metal ductwork remains a timeless option due to its durability.

So, which type is best for your HVAC system? The answer will depend on your unique needs and preferences, plus the recommendation from your duct installer. Carefully consider the pros and cons of flexible ducts with the help of this guide.

Ductwork is the system of tubing that circulates air throughout your home. It is an essential part of your HVAC system, which is why choosing the right HVAC duct type is vital.

Flexible ducts, also known as flex ducts, are made up of a coiled metal wire and a flexible plastic material. It’s covered by an added layer of fiberglass for insulation and a vinyl or foil jacket. True to its name, flex ducts can easily bend around objects and fit into tight spaces.

| Pros | Cons |

|---|---|

| Cost-effective | Requires more energy |

| Easier and quicker installation | Not as durable |

| Less noise | Susceptible to issues |

| Fewer leaks | Shorter lifespan |

Consider the advantages of installing flexible ducts in your HVAC system.

Flexible ducts are made of less expensive materials and take less time to install than metal ducts, resulting in lower installation costs. This duct type also requires less skill and energy to install, which saves on labor costs.

Flexible ducts are adaptable and can easily fit into tight spaces. Your duct installer can cut flexible ducts to accommodate any area of your home. Thanks to this feature, it’s easier to measure and place flexible ducts, making for a much easier and quicker installation process.

Metal ducts are prone to vibrations, whistling, and other noises. Flex ducts, on the other hand, absorb sound rather than conducting it. This benefit reduces unwanted noises throughout your home.

Flexible ductwork comes with seamless insulation and doesn’t require any sealant in its original form, whereas metal ducts’ seams must be sealed. As a result, flex ducts are less likely to leak heated or cooled air, so you won’t need to test ductwork for leaks as often.

Consider the disadvantages of installing flexible ducts in your HVAC system.

Since flex ducts must bend around obstacles and fit into tight spaces, airflow can become restricted. That means more energy is required to circulate air through your home, which can lead to more expensive energy bills.

Unlike metal ducts, which are extremely durable, flexible ducts are made with less durable materials. The use of less expensive duct materials can lead to wear and tear as time goes on. That means you’ll likely have to repair and replace parts of the ductwork more often.

Flex ducts are more prone to tearing, twisting, kinking, compression, and other issues. Pests, such as rodents, squirrels, and raccoons, can also chew through ductwork, leading to even more serious problems.

When properly cared for, metal ducts can last more than 25 years. On the other hand, flex ducts don’t last more than 20 to 25 years. However, proper installation and regular maintenance can maximize the lifespan of your flex ducts.

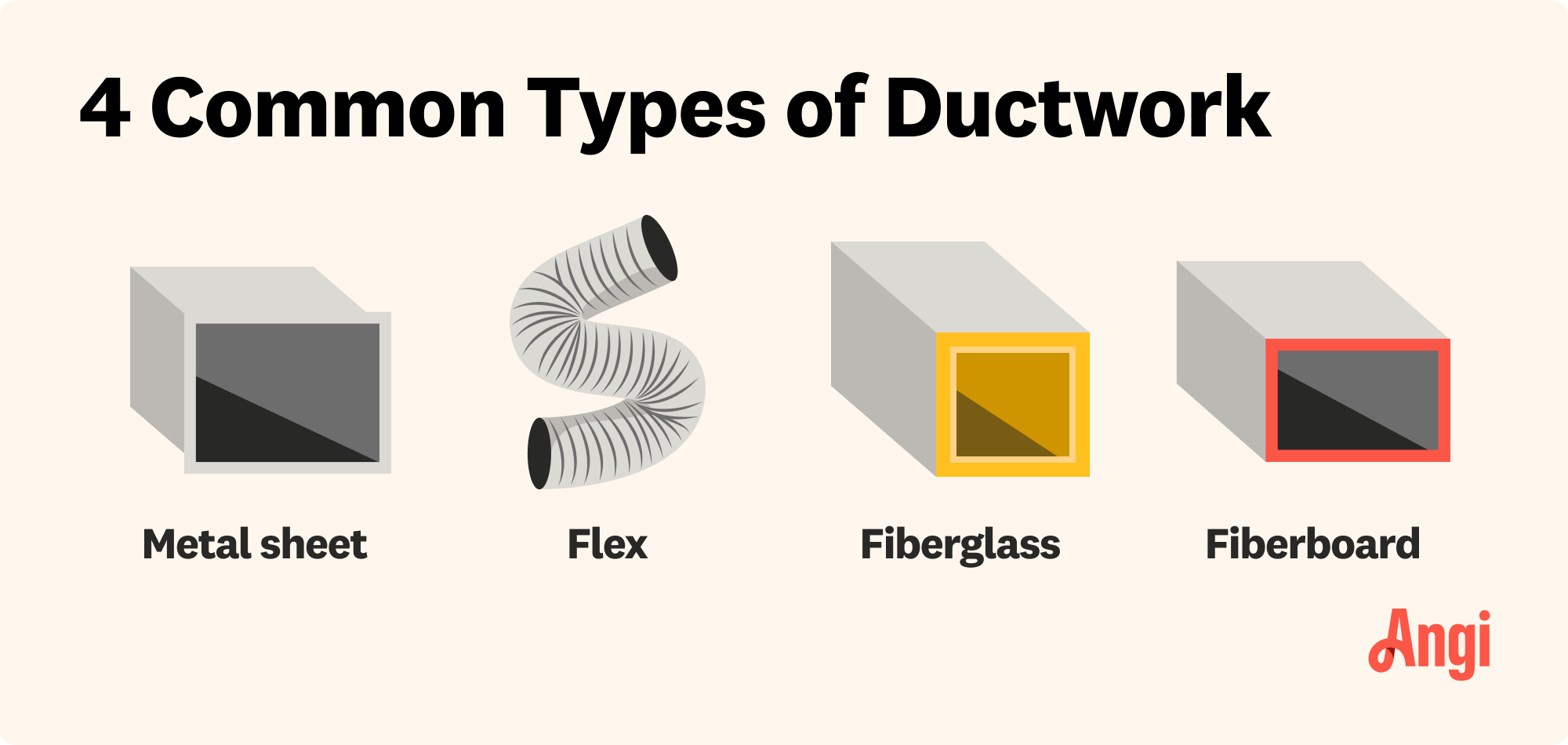

After weighing the pros and cons of flexible ductwork, you may be interested in exploring alternatives that could be an even better fit for your HVAC system. Of course, metal ductwork is the most common type because it’s made of sturdy materials, like galvanized steel or aluminum, and it’s a long-lasting and durable choice.

Fiberboard and fiberglass are two other options. Fiberboard is made of resin-bound fiberglass strands and can maintain temperatures for longer periods of time. However, it can also be harder to keep clean. Fiberglass is great at reducing heat loss and noise, but it may not be the most durable option.

Whether flexible ductwork is right for you will depend on factors such as your budget, the size and layout of your home, and your unique heating and cooling needs. If you’re looking for an affordable, easy-to-install option, flex ducts may be the ideal choice.

It’s also possible to use metal and flexible ducts for your HVAC system; this way you can reap the benefits from both types of ductwork. Consult with a duct installer near you for guidance. A pro can take into consideration your specific needs and wants, and then provide the right expertise and service for you.

Flexible ductwork is one of the cheapest and easiest options to install in your house. Flex duct material costs $1 to $3 per linear foot when non-insulated and $2 to $4 per linear foot with insulation. Labor for professional installation costs between $5 and $10 per linear foot, bringing the total cost to $6 to $14 per linear foot. That comes to an average cost of $1,000 to $1,500 to install flexible ductwork in a standard-sized house.

Installing your own ductwork might sound like an easy way to save money, but it’s best to leave the installation to the pros unless you have extensive ductwork experience. While flex ductwork is one of the easiest types to install, it’s still a tricky process that can lead to serious issues if installed improperly. Those issues include everything from air leaks and decreased energy efficiency to damaged HVAC systems and failed home inspections. As a result, we recommend contacting an HVAC technician or an air duct installer in your area.

From average costs to expert advice, get all the answers you need to get your job done.

Furnace cleaning is an essential annual chore to keep your home safe. Find out common furnace cleaning costs by type and size of furnace with this guide.

Repairing ductwork in a crawl space is frustrating and difficult, which is reflected in the cost. Learn why limited access results in a premium cost beyond just a simple increase in labor hours.

HVAC replacement costs depend on a lot of factors, like unit type, size, and labor. See what you can expect to pay for HVAC replacement here.

Baseboard heater covers can endure a lot of wear and tear, but eventually you’ll want to replace them. Here’s the best way to switch out baseboard heater covers.

A problem with your heat pump can lead to a house that’s too cold or too hot. Learn the most common heat pump problems—including any weird noises—and their solutions.

Do you have a clogged AC drain line? We dig into the reasons behind those pesky blockages and how to clear them for optimal AC performance.