Gas furnace replacement costs depend on the type of furnace you want and installation fees. Our guide explains all the factors involved in a new furnace cost.

Get your ducts in a row

Both flexible and rigid ducts distribute air throughout your home.

Flex ducts are less durable but more cost-effective and easier to install.

Rigid ducts are long-lasting but can be trickier to install due to their inflexibility and weight.

You have ductwork to thank for distributing air throughout your home and keeping a comfortable temperature year-round. If you're considering upgrading or installing your home's HVAC system, you need to choose between different types of ductwork: flex or rigid. Learn how these two duct types compare so you can choose the one that works for you.

Flexible ductwork can be made from silicone, rubber, plastic, or plastic-coated fabric, while rigid ducts are made from aluminum or steel. While flexible ducts can change size to fit a particular area, rigid ducts are always the same size and may be shaped like tubes or rectangles.

Other key differences between flex and rigid ducts include their price, ease of installation, and longevity.

Flex ducts are lightweight and tube-shaped with an accordion-like structure that can bend and twist around objects, giving them a lot of versatility on where you can use them. Typically, they have three components: the wire coiling, insulation, and the covering. The covering on a flex duct is commonly made of aluminum but can be made out of a number of materials ranging from plastic, silicone, or fabric.

Flex ducts can come with or without insulation. Insulated flex ducts can regulate heat loss or gain, whereas uninsulated ducts are better for homes in regulated climates where drastic temperatures don’t occur.

| Pros | Cons |

|---|---|

| Lower cost | Require support |

| Easy installation | Shorter longevity |

| Fit into tight spots | Reduced efficiency |

Best for:

Homes with lots of tight areas

Budget-conscious homeowners

One of the biggest benefits of flexible ductwork is its lower cost than rigid ducts. Thanks to their light weight and malleability, they are also much easier to install. You can install flexible ductwork in places that are too small or oddly shaped for rigid ducts.

Flexible ductwork's malleability can sometimes work against it. The ducts require some form of support to prevent sagging. Since they aren't as smooth on the inside as rigid ducts, they may not be as energy efficient.

The biggest drawback to flexible ductwork is that they don't last nearly as long as rigid ducts. Their flexibility can make them more prone to snags and tears.

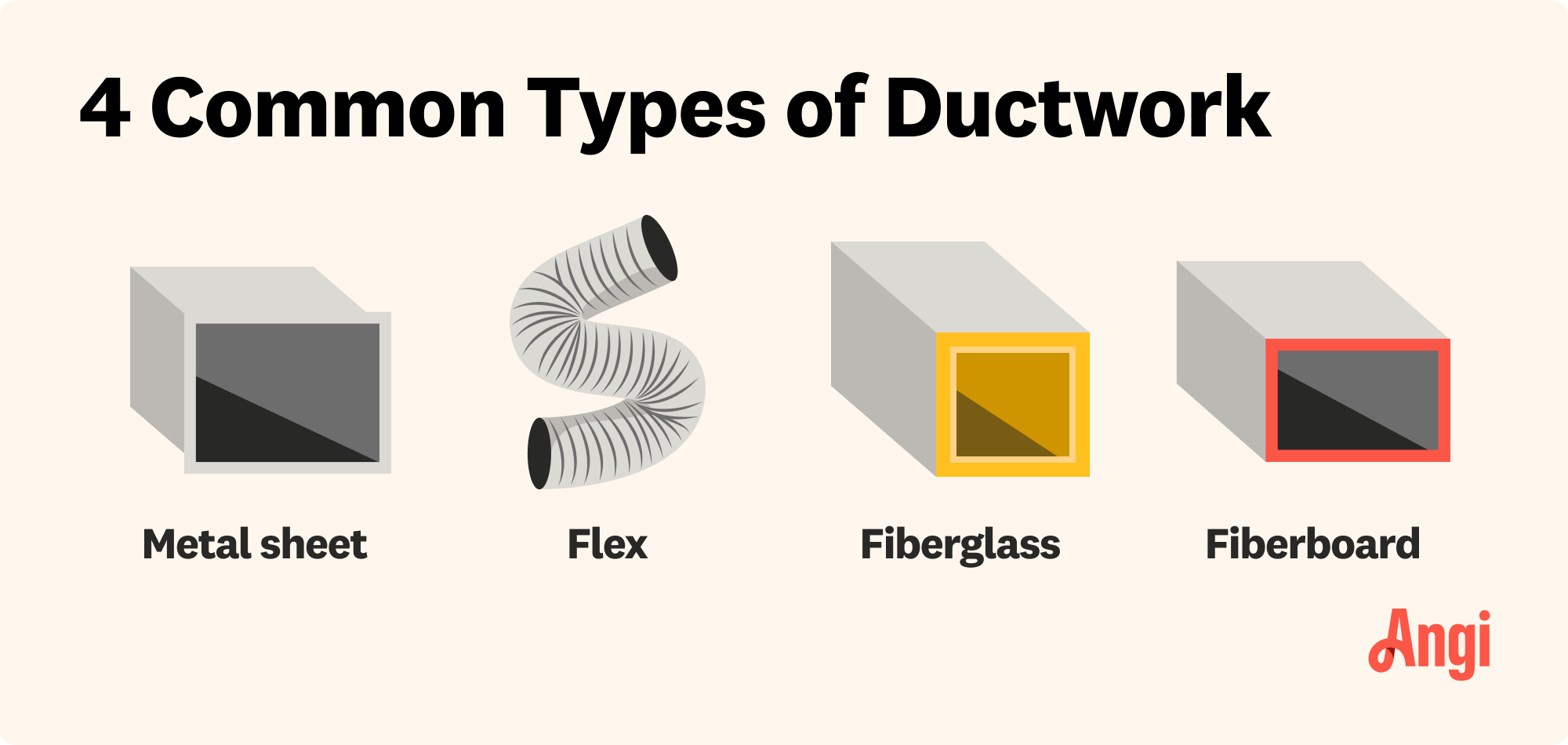

Rigid ductwork is made from a more structurally sound material but is less forgiving during the installation process. The most common type of rigid duct is galvanized steel (also known as steel ducts), but other materials include aluminum, fiberglass, and fiberboard.

Rigid ducts come in three shapes: rectangular, round, and ovular. In recent years, semi-rigid ducts have come into the market, offering more installation flexibility and cutting down on some of the labor costs.

| Pros | Cons |

|---|---|

| Longevity | Higher cost |

| Greater efficiency | Complicated installation |

| Easy cleaning | Requires precision |

Best for:

Homes in areas that see extremely hot or cold temperatures

Whether made of aluminum or steel, rigid ductwork is built to last. Unlike flexible ducts, it won't snag, tear, or kink. Since the inside of the ducts is completely smooth, air can flow through them more efficiently, leading to lower energy bills. The ducts are also easier to clean compared to flexible options.

The big drawback of rigid ductwork is its price. It costs much more to install rigid ductwork than flexible ducts, and rigid duct replacement costs are also higher due to the complexity of installation.

Rigid ductwork weighs a lot, so it requires more people during installation. A local professional duct installer will also have to cut rigid ductwork to an exact length and ensure that the width of the ducts works in the space.

Here's how flex ducts and rigid ducts stack up.

Rigid ducts win hands down when it comes to durability. Thanks to their sturdy metal material, they resist rust and mold growth and can last for decades.

While rigid ducts win for durability, flexible ducts give them a run for their money. Flex ducts are more affordable, ranging from $1 to $4 per linear foot versus $7 to $13 per linear foot for metal.

Since they have a simpler installation process, the cost to install or replace flexible ducts is also lower than for rigid ducts.

Both rigid and flex ducts can make noise while they work. While the shape of rigid ducts can help them direct sound more smoothly and dampen the hum of airflow, you may hear noise if they become blocked or turn at certain angles.

Flex ducts may also produce noise due to their walls' ability to contract and expand in response to changes in temperature and air pressure. However, flex ducts can also reduce noise if they're made of non-metal materials such as fiberboard or if they're installed at the end of the ductwork system.

All ducts generate noise, but some sounds are cause for concern. A gentle humming or clicking is normal, but loud rattling, banging, buzzing, or whistling means you may have a problem requiring professional help. Some factors that cause excessively noisy ducts include dents or damage, loose metal parts, dirty or blocked vents, and closed dampers.

Once again, flex duct wins for installation ease. The ductwork weighs less, which makes it easier to maneuver. It's also more forgiving in tight areas. Because you can scrunch it, there's more leeway when cutting the ductwork, too.

Rigid ducts are easier to clean than flex ducts, as dirt and debris are less likely to get trapped inside them. Since they resist rust and mold growth, you don't have to worry as much about cutting the ductwork in place to replace sections of it.

Flex ducts require more frequent cleanings than rigid ducts, to keep dust and debris from collecting inside.

Thanks to the smooth interior surface, air flows easily through rigid ducts, which can help your HVAC heat or cool your home more efficiently. While flex ducts can still heat and cool your home, they do so with slightly less efficiency, thanks to the uneven texture inside.

The cost to replace air ducts ranges from $455 to $2,185, with the average person paying $1,250. If you’re starting your duct framework from scratch, costs depend heavily on the type and installation method. The cheapest option is exposed ductwork, which costs between $1,600 and $4,800 or an average of $2,200.

The price you pay will depend on your home’s size, the condition of your interior walls, which types of ducts you choose, and any repairs needed.

While it may save you some money, installing air ducts yourself isn’t recommended unless you’re an extremely skilled DIYer. The labor costs associated with this project can range anywhere from $2,000 to $5,000, depending on the professional and the job scope. However, a lot can go wrong if you install air ducts yourself improperly, such as leaks, HVAC damage, poor energy efficiency, and insurance issues. Ultimately, it’s not worth the price of your time or the risk to do it yourself, so hire a local air duct professional for the job.

From average costs to expert advice, get all the answers you need to get your job done.

Gas furnace replacement costs depend on the type of furnace you want and installation fees. Our guide explains all the factors involved in a new furnace cost.

Discover the cost to install ductwork. Learn about average prices, cost factors, and tips to save money on your ductwork installation project.

Discover the primary whole-house air filtration system cost factors when installing one in your home to help remove airborne contaminants and allergens.

Learn how to add Freon to your AC unit with our step-by-step guide, and keep your home cool with a properly functioning AC unit.

No one likes a cold shower or a frigid winter night. Regular boiler maintenance and repair will ensure your appliance stays in tip-top shape. Keep the hot water flowing year-round with these easy tips.

A whole-house humidifier costs between $400 and $800, but can have an ROI of 40%. Learn if adding this HVAC appliance is worth it for you.