Furnace cleaning is an essential annual chore to keep your home safe. Find out common furnace cleaning costs by type and size of furnace with this guide.

Ducts work better together—here’s how they’re joined

Hire a duct installer to handle the duct joints, as this isn’t a DIY-friendly project.

Installing your own ducts without the help of a pro is illegal in some locations.

S and D cleats are the most common fittings for ducts that emit low to medium amounts of pressure.

Expansion joints may be necessary if your aim is to increase the range of airflow in your home.

When it comes to a properly functioning HVAC system, ductwork is something of an unsung hero. Even with the best air conditioner or furnace in the business, you’d be out of luck without the series of metal pipes or tubing that runs through your home, regulating airflow and ensuring every space is evenly cooled or heated.

Of course, ducts don’t just arrive pre-assembled and perfectly sized for your home. They must be constructed and retrofitted to meet your home’s needs, which usually means that separate pieces of ductwork need to be joined together—that’s where duct joints come in.

To understand how duct joints work, we must understand what ducts are made of. There are a few different types of ductwork out there, including rigid, semi-rigid, and flexible ductwork.

Rigid ductwork is most common and is usually made of sheet metal, like galvanized steel or aluminum (which is also what semi-rigid ductwork is made of). This type of ductwork may also be made of fiberglass or incorporate fiberglass insulation.

Flexible ductwork is made of flexible plastic and metal wire and can be bent and shaped to suit a home’s needs.

Different types of ductwork use different types of duct joints, though all these joints have the same purpose: to link together ducts and help air move efficiently and properly through the system. Duct joints may be screwed or riveted into place, sealed with a sealant, or welded.

Let’s dig into the different ways in which ducts are held together.

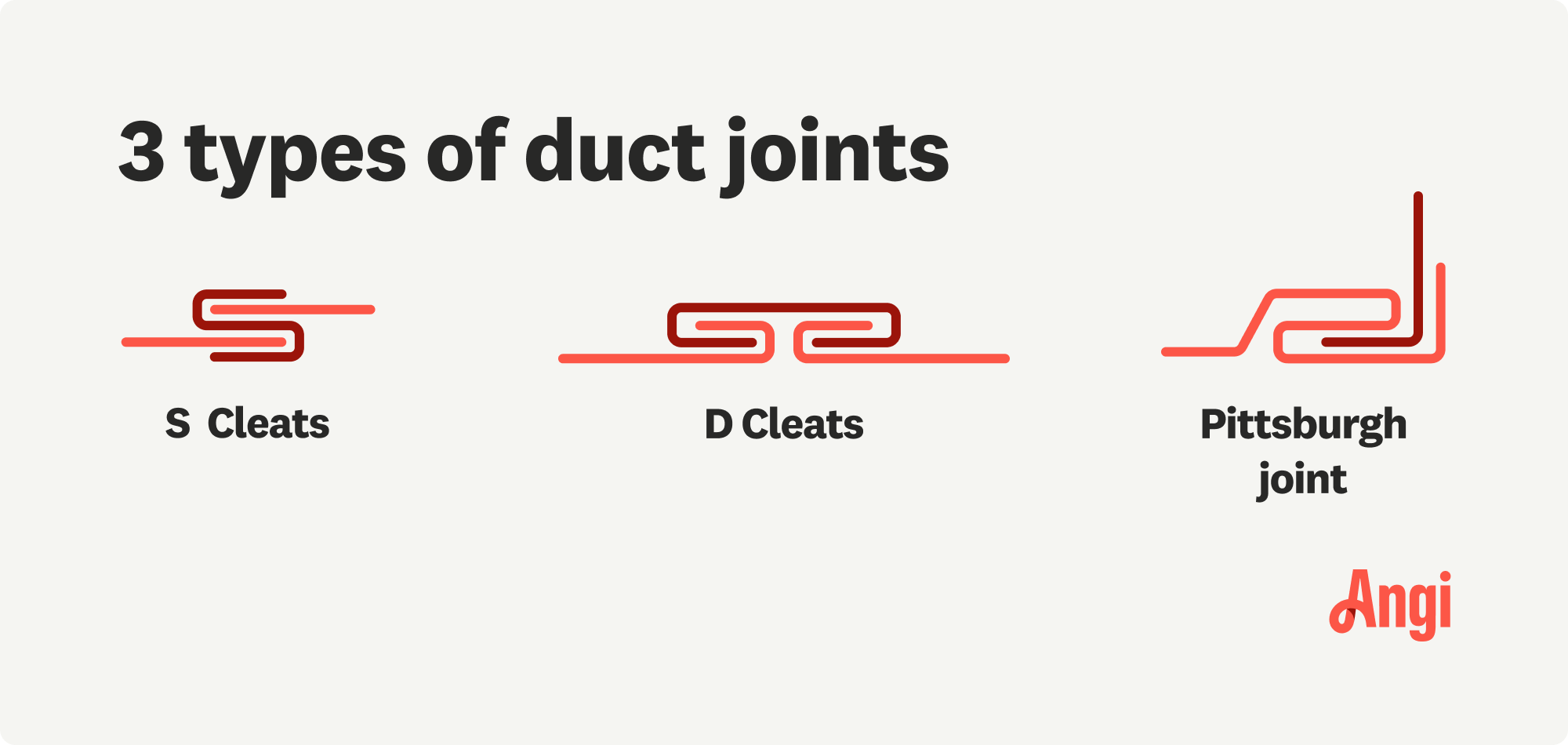

Also known as a Pittsburgh lock or Pittsburgh seam, Pittsburgh joints occur longitudinally along the duct—that is, the long way down, not the short way across. These are less of a joint holding multiple ducts together, and more part of the way each individual duct is constructed.

Pittsburgh joints are specifically designed using overlapping layers of metal that can handle pressure increases and decreases, which ducts must allow as air flow and temperature expands and contracts the metal.

S cleats and drive cleats, also known as D cleats, are the components that make up the connective fittings that can be slipped together along the transverse portion of the duct—which is the wide part rather than the long one, i.e., where the ducts connect to one another.

The S cleat runs along the top of the duct, while the drive cleat runs along its height from top to bottom, and the two are molded in such a way to fit neatly into each other. They are then hammered into place. This is one of the most common ways ducts are fitted together in commercial settings or for HVAC systems that put out low to medium air pressure.

Ducts can also be fitted together using a transverse duct flange (TDF) joint, which refers to a lifted metal piece at the end of the duct that can be fitted onto a similar TDF joint on another duct. In other words, rather than the ducts fitting neatly together with cleats, the transverse duct flange joint allows them to be riveted together along the flanges themselves, which join up.

A slip joint, in ductwork, is basically what the S and D cleats create together: a system where the ducts can be simply slipped onto each other, and then hammered and perhaps riveted into place.

In some cases, especially in industrial or commercial capacities with greater range of air flow and temperature, expansion joints can be used in ductwork, which incorporate a fabric section that allows the joints to more fully expand and contract as needed.

In some cases, you may need your ducts to bend in order to fit into your home’s space—which is where duct elbows come in. Prefabricated of sheet metal and available from home improvement stores, duct elbows can help you get your ducts moving around corners or through vertical space.

In some cases, you may also need to make a shift between one size of duct and another within your ductwork system in order to regulate air flow or meet your HVAC system’s requirements. A duct reducer is a metal joint that’s wider on one end and narrower on the other, allowing you to easily make this shift.

Finally, your ducts are pointless unless they actually lead to an air vent, or register, in your house—which is where duct boots come in. With one circular end (to fit your ducts) and one rectangular end, duct boots work to connect your ducts to your air registers, where air flows out into your home. That means that your HVAC system can do its job and keep your home nice and warm (or cool, depending on the season).

Still have questions about the types of duct joints that’ll get your home’s air flowing properly—or ready to get started on your project? Your local duct installer can answer your questions and help you get going.

Duct installation or replacement costs $1,250 on average, though most homeowners will spend between $450 and $2,180 on the project. Duct installation costs depend on the duct material you choose, the complexity of the ductwork, and the size of your home.

Flexible, non-insulated duct material costs $1 to $ per square foot, whereas flexible, insulated duct material costs more—$2 to $4 per square foot.

Duct installation is not a DIY-friendly project, and in many areas, it’s not legal to do this work on your own. A professional is often required to install your ducts, due to local codes. Furthermore, improper installation could lead to leaks, damaged ducts, poor energy efficiency, and warranty invalidation. It’s best to call a duct professional to handle installation.

Very professional, polite and helpful. I would recommend him!

Raven and crew does absolutely fantastic job. They are very professional if any concerns were to occur with any of her work she always took responsibility and finished out with a great job. I have worked with her business for a year and have always been satisfied. Very trusted business and...

I had Ace Fireplace Services install custom chimney caps for my home, and the results are stunning. They fit like a glove and have added a touch of sophistication to my chimney. I can't recommend their services enough.

Precision and professionalism define Custom Paint Jobs LLC. We couldnt be happier.

Very professional and efficient with work. Answered each question I had with great knowledge and an informative response. Will be working with them again.

Window Depot did an amazing job on my deck. I wasnt sure what I wanted to do, but their composite decking was affordable and will last a long time. I am excited to have family over, and I am no longer embarrassed by my backyard. Jeff and the ground crew were polite, respectful, and caring for...

Great tree company, very professional and honest. Glad we found them, they had the best pricing

Great experience all together. Dog friendly, courteous, great results and honest with recommendations. Will certainly be using Cardinal in the future for any carpet repairs

Maple Tree Service should serve as a mentor for other business! Customer service was superior and beyond expectation. Response to request was prompt. The representative was very courteous and proud of the company. Quote was given during initial visit and work date established. A follow up...

Eugene returned my call within minutes and was able to complete the job within a couple of days. Friendly and professional, and I feel his prices are reasonable.

From average costs to expert advice, get all the answers you need to get your job done.

Furnace cleaning is an essential annual chore to keep your home safe. Find out common furnace cleaning costs by type and size of furnace with this guide.

What you’ll pay in Columbus, OH, for furnace repairs depends on many factors. Here’s a breakdown of what can go wrong and the cost to fix those issues.

Regularly replacing your HVAC filter regularly is vital for a healthy system. Learn how much an HVAC filter replacement costs with this informative guide.

With so many types of furnaces out there, how do you know which one is best for you? Explore our guide to the five main types and get your home warmed up.

Not sure who to hire to install radiant floor heating? Learn which pros handle radiant floor heating installation and how the work comes together.

Learning how to secure a window AC unit will avoid personal injury and damage to your home. It will also protect against theft and break-ins.