Do you know what it will cost to reroute ductwork in your home? Discover the cost factors and other considerations of this HVAC project.

Size matters for proper airflow

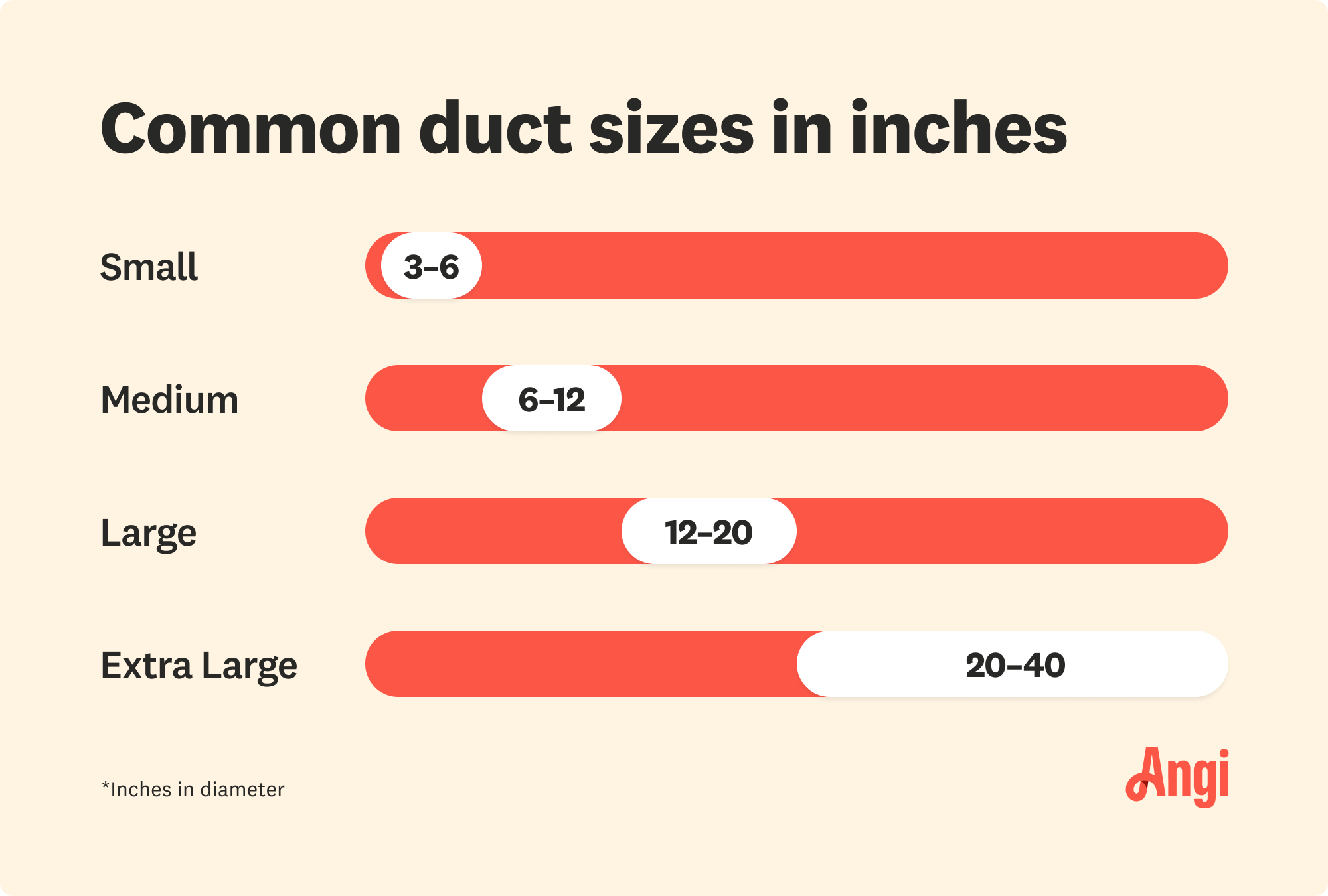

Standard duct sizes are between 6 and 12 inches in diameter.

The two types of ductwork are rectangular and round.

Duct sizes are influenced by home size, ductwork layout, and HVAC capacity.

The size of your ductwork greatly impacts the efficiency of your home's HVAC system, influencing everything from your energy consumption to room comfort. Several factors play into the ideal duct size, including home size and duct layout. Understanding common duct sizes can be useful when planning for ductwork installation in your home.

When taking on this project, expect questions only a pro can answer. With our network of local pros, you'll get the job done and your questions answered—without the hassle and stress of doing it yourself.

The most common duct sizes for residential HVAC systems are 6 to 12 inches in diameter. Overall, ductwork can measure 3 to 20 inches in diameter depending on which types of ductwork are installed and other household factors. In commercial buildings, ductwork can range in diameter between 24 to 40 inches.

| Type of Ductwork | Minimum Diameter (Inches) | Maximum Diameter (Inches) |

|---|---|---|

| Rectangular | 3 | 40 |

| Round | 4 | 40 |

Rectangular or square duct sizes vary widely and are chosen based on airflow requirements and spatial restraints. Common HVAC duct sizes for home systems range from 8x8 inches to 24x24 inches, with smaller ducts used for branch lines and larger ducts for main trunks.

Rectangular ducts work best in homes with limited space since they can fit within ceiling cavities, walls, or other tight areas where round ducts can’t.

Round duct sizes are commonly used in both residential and commercial HVAC systems due to their efficiency and ease of installation. Sizes range from 4 to 16 inches in diameter, with 6 to 10 inches being the most common for main supply and return ducts.

Their round shape allows for smoother airflow with less resistance, which can enhance your HVAC’s efficiency. The uniform cross-section also helps minimize dust and debris build-up, making them easier to clean and maintain.

Measuring duct sizes begins with calculating the airflow requirements for each room, measured in cubic feet per minute (CFM). This calculation considers factors such as room size, number of occupants, windows, insulation, and intended space use.

Once you know the CFM for each room, the next step is to design the ductwork layout and select appropriate duct sizes. This involves using the CFM values and consulting duct sizing charts or software to match the airflow requirements with the correct duct dimensions.

The goal is to ensure each duct can handle the required airflow without causing excessive pressure drops or noise. Additionally, considering the total equivalent length of the duct runs, including fittings and bends, is crucial to account for any added resistance.

A local air duct installer can take care of this process to ensure your home has the appropriate duct size for optimal HVAC performance.

Key factors come into play when determining the right duct size for your home. The size makes a difference in not only the comfort of the home but on how efficiently the HVAC system can operate.

Home size directly influences duct size because larger homes require more extensive ductwork to distribute conditioned air evenly throughout the space. The total square footage, number of rooms, and home layout all contribute to the calculation of airflow needs. Larger homes with more rooms and higher CFM requirements require larger or more ducts to ensure adequate airflow and maintain consistent temperatures.

Proper duct sizing based on home size is essential to avoid issues such as inadequate heating or cooling, uneven temperature distribution, and increased energy consumption, ensuring the HVAC system operates efficiently and effectively.

Ductwork layout design must account for the distance air needs to travel, the number of turns, and any obstacles. A complex layout with many bends, long runs, or multiple branches requires larger ducts to maintain adequate airflow and minimize pressure loss.

Each turn and fitting adds resistance, which can require an increase in duct diameter to compensate. Efficiently planned layouts with shorter, straighter runs can use smaller ducts while delivering the required airflow.

The HVAC system capacity dictates the air volume that needs to be distributed throughout your home. A higher-capacity system, designed to heat or cool larger spaces or higher load demands, requires larger ducts to accommodate the increased airflow without causing excessive pressure drops or noise.

Properly sizing the ducts to align with your HVAC system’s capacity ensures that the system can deliver the desired temperature control and maintain energy efficiency while preventing strain on the equipment.

The wrong duct size can lead to several issues that affect your HVAC system efficiency and the comfort of your home. Undersized ducts can restrict airflow, causing the system to work harder to heat or cool the house, which increases utility bills.

This added strain can lead to more frequent breakdowns and a shorter life span for the HVAC equipment. Additionally, restricted airflow causes uneven temperature distribution, with some rooms being too hot or cold.

If you have the wrong duct size, the best course of action is to consult a professional HVAC technician to assess and redesign the ductwork. This may involve resizing the existing ducts, adding new ducts, or modifying the layout to improve airflow and efficiency. In some cases, installing dampers to control airflow or upgrading to a more powerful HVAC system may be necessary.

Air duct replacement costs between $1,400 and $5,600. Home size factors into the cost, with larger homes between 3,000 and 4,000 square feet paying up to $9,000 to replace ductwork. The ductwork material makes a difference as well, with flexible ductwork, insulated or non-insulated, costing between $1 and $4 per linear foot. Fiberglass and sheet metal ductwork are on the higher end, with fiberglass costing $4 to $6 per linear foot and sheet metal ranging between $7 and $13 per linear foot.

Duct replacement is a serious job that’s best left to a local HVAC professional. This job requires specialized knowledge in a number of fields, including HVAC systems and wall demolition. Additionally, pros use unique tools like sheet metal shears to cut, bend and connect duct sections. Other specialized tools include duct brakes and crimpers.

While DIYing this job is possible in select scenarios, improper installations lead to an imbalance in air distribution. This means higher energy bills and uneven temperatures throughout the home. In rare cases, poor duct installation can lead to carbon monoxide leaks, electrical issues, and fires.

From average costs to expert advice, get all the answers you need to get your job done.

Do you know what it will cost to reroute ductwork in your home? Discover the cost factors and other considerations of this HVAC project.

Heating and cooling system on the fritz? Discover the factors that go into HVAC repair costs and how you can save money on this crucial home update.

When your heat goes out, it can cause a bit of a panic. But knowledge is power, so let's go over radiator repair costs before that happens.

Discover heat exchanger replacement costs to learn about price factors, labor, and ways to save before hiring a pro or starting your project.

Energy bills rising? Here’s how to perform a DIY duct leakage test to locate any damage in your ductwork and restore your energy-efficient home.

Wondering who to hire for swamp cooler installation? Learn when to call an HVAC contractor, electrician, or handyperson, and what to expect.