The average cost of an electric furnace ranges between $1,700 and $7,000, depending on the size, ductwork, and complexity.

Channel your home’s energy with the right kind

Sheet metal ducts have the longest life and can last from 30 to 50 years.

Most HVAC ducts last around 15 years and should be replaced as they reach the end of their life.

Fiberglass-lined ducts can affect indoor air quality and are harmful to those with asthma, sinusitis, or other respiratory conditions.

Talking to an HVAC duct installation pro before installing new ducts in your home can help minimize potential risks and hazards.

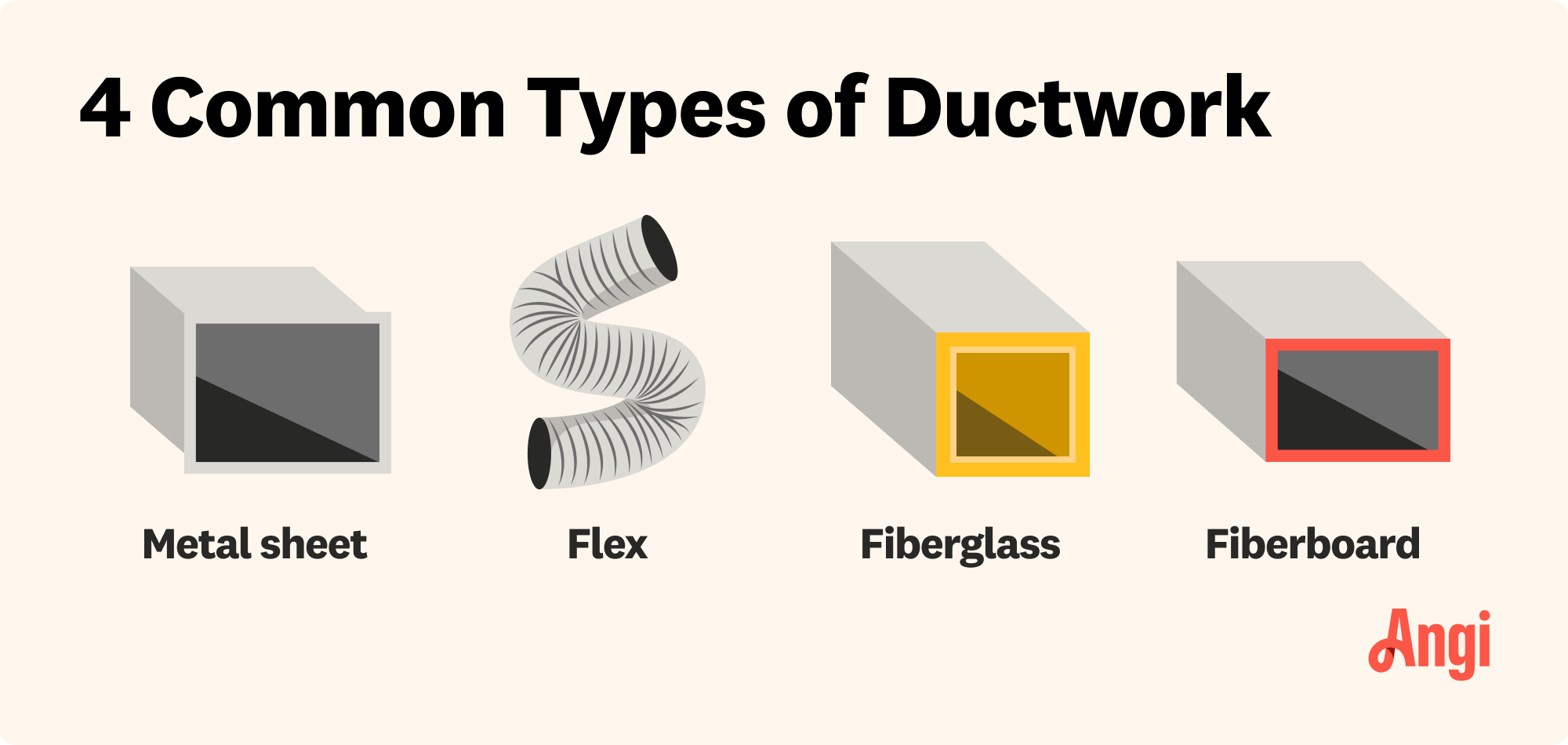

Ductwork is the hidden backbone of your home’s HVAC system. While you may not be familiar with all the HVAC duct types that are out there, it helps to know which variety is in your home or which type works best should you need a repair or complete replacement.

| Type of Ductwork | Lifespan in Years |

|---|---|

| Flexible | 10–15 |

| Sheet metal | 30–50 |

| Fiberboard | 10–20 |

| Fiberglass lined | 15–25 |

Quality ductwork will increase the efficiency of your HVAC, sometimes by 20% to 30%. This is because there is reduced air leakage due to better insulation and more optimized airflow. This means your HVAC doesn't have to work as hard to keep the desired temperature, so it uses less energy.

Flexible ductwork consists of a metal wire coil covered by a layer of plastic. Its thermal insulation is made of glass wool, which helps reduce heat loss or gain and improves energy efficiency. This type of ductwork is commonly used in smaller, single-story homes with tight spaces.

| Pros | Cons |

|---|---|

| Budget-friendly | Damages easily |

| Easy to install | Prone to sagging |

| Good for small spaces | Can restrict airflow over time |

Best for: Smaller homes with tighter budgets

As its name suggests, sheet metal ductwork is made of galvanized steel, aluminum, or stainless steel. This type of ductwork can be shaped into round, spiral, or rectangular ducts and is one of the most durable types available. It falls on the higher end of the price range due to its ability to resist mold and pests.

| Pros | Cons |

|---|---|

| Durable | More expensive |

| Resistant to mold and pets | Requires professional installation |

| Promotes good airflow | Prone to air leaks |

Best for: Larger homes in humid or extreme climates

This ductwork type consists of compressed resin-bonded fiberglass topped with a foil laminate to prevent moisture buildup and leakage. Because of its rough material, it can be prone to trapping dust and debris, so it helps to consider the cost of air duct cleaning if you’re thinking about installing fiberboard ductwork.

| Pros | Cons |

|---|---|

| Built-in insulation | Shorter lifespan |

| Budget-friendly | Can trap dust and debris |

| Reduces noise | Less airflow efficiency |

Best for: Small homes in moderate climates

Fiberglass-lined ductwork is made of sheet metal ducts coated with a layer of fiberglass insulation. It’s beneficial for open spaces that need noise control and more consistent thermal control.

The main downside is that it’s possible for fiberglass-lined ducts to deteriorate and release small particles of fiberglass into the air, which can be harmful for people who struggle with breathing conditions like asthma.

| Pros | Cons |

|---|---|

| Improved insulation | Can affect indoor air quality |

| Quiet | Shorter lifespan |

| Controls condensation | Difficult to clean |

Best for: Commercial buildings or offices

Don’t try to climb up into an attic to learn more about duct systems. A local ductwork installer can take a look at your home or plans for your home to make recommendations on the right type of ductwork for you. HVAC ductwork can make the difference between a well-heated home or one that harbors mold and has you shivering in below-freezing temperatures.

From average costs to expert advice, get all the answers you need to get your job done.

The average cost of an electric furnace ranges between $1,700 and $7,000, depending on the size, ductwork, and complexity.

Here's what you can expect when getting an estimate for coolant leak repair costs. The cost can vary based on the detection method used, the source of the leak, and the amount of damage that needs to be repaired in the aftermath.

Discover how much R-22 refrigerant costs per pound based on factors such as the size, age, and location of your HVAC unit.

With so many types of furnaces out there, how do you know which one is best for you? Explore our guide to the five main types and get your home warmed up.

How to clean your air conditioner depends on the unit type. Sometimes, a good hose-down is all you need if you have centralized AC. This guide can help with the cleaning process.

You’ll need to get creative if you want to run your portable AC in a windowless room. Here’s how to vent a portable air conditioner without a window.