Dealing with a visibly damaged roof or leak? Learn about roof repair costs in Columbus to see how much you’ll need to budget for a permanent solution.

Torch down roofing is a go-to for flat roofs

Torch down roofing involves heating sheets of modified bitumen.

The sheets bond together to form a waterproof and fire-resistant seal.

Torch down roofing works best on flat and low-slope roofs.

The pros are that it’s low cost and low maintenance.

The cons are that it’s easily damaged and tricky to install.

Roofing is a little more complicated when you have a roof with very little pitch to it. In situations like this, you can't just install ordinary shingles, so you should explore alternatives.

Torch down roofing is one of those options. It's a unique roofing method that will give your roof a beautiful finish and waterproof protection. Here's what you should know about this method, including how much it costs and its pros and cons.

The average cost to replace a flat roof, including materials and labor, is $3,100 to $9,600

Torch down roofing involves laying out sheets of modified bitumen and then using a hand-held propane torch to heat the material so it bonds permanently with the roof. It’s used most commonly on homes with flat roofs or a very slight pitch, as opposed to the steep-pitched roofs most homes have.

The bitumen used for this type of roofing is typically modified with rubber or plastic, which means it can expand and contract without resulting in any damage. The reason you would use this type of roofing instead of standard shingles for a flat roof is that shingles are meant to assist a roof in draining water quickly and efficiently.

If there is no slope, the water will start to pool and may find a way through the cracks and crevices of the shingles and into the underlayment and roof trusses. But with torch down roofing, there’s a watertight seal between the bitumen sheets.

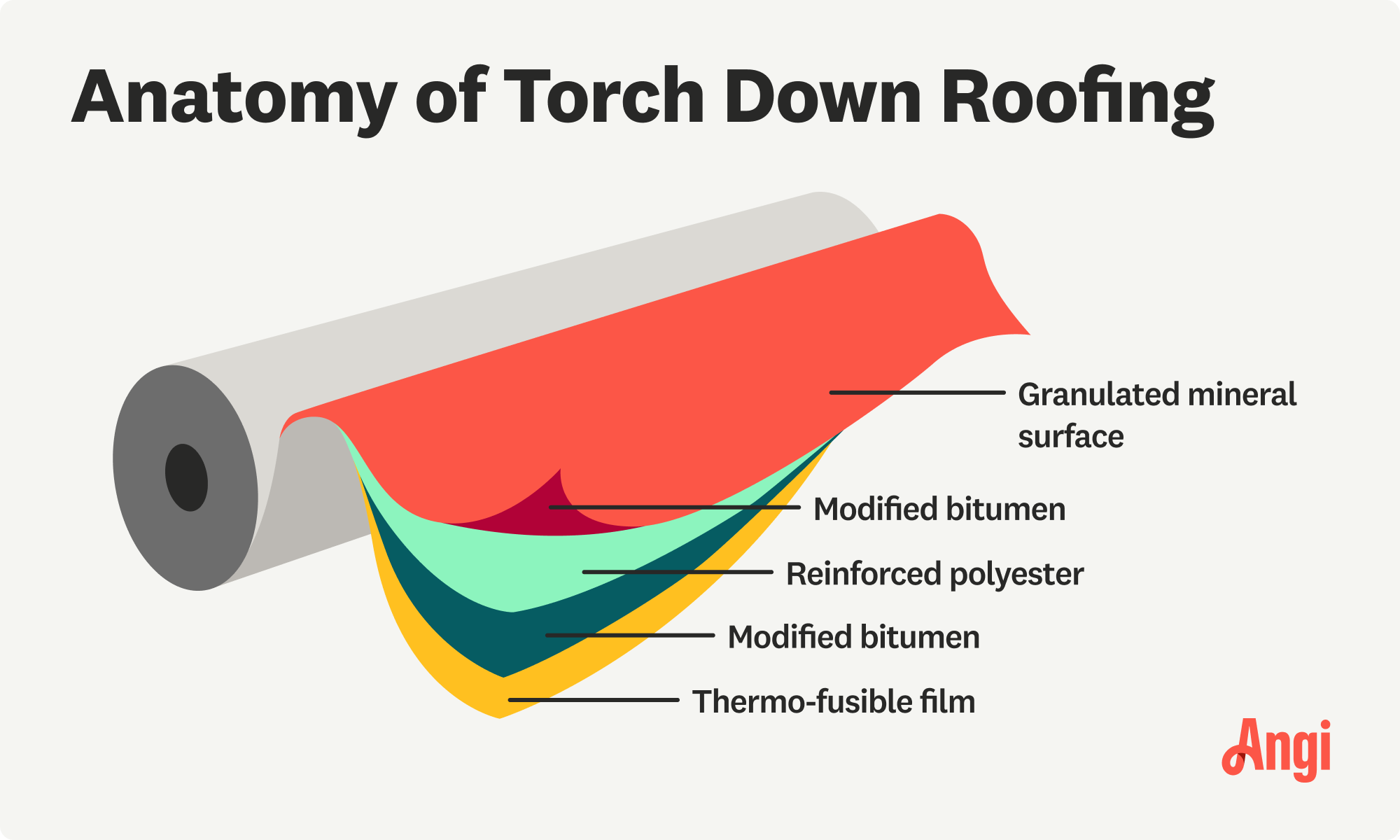

Each torch down roofing membrane contains a few layers made from different materials. The primary material is modified bitumen, which you’ll find in the second and fourth layers. Manufacturers mix bitumen with either plastic or rubber:

Atactic Polypropylene (APP): This torch down roofing material is a type of plastic. It’s flexible enough to withstand both high and low temperatures.

Styrene Butadiene Styrene (SBS): This polymer is a form of synthetic rubber. It’s also flexible but has a lower melting point than APP. Therefore, it is suitable for torch down roofing, self-adhering, and cold-processed roofing. It’s ideal for cold-weather climates.

In addition to layers of modified bitumen, your torch down roofing membrane will have a bottom layer of thermo-fusible film, a layer of reinforced polyester, and a top layer of granulated minerals.

Different roof types have different components. When installing a torch down roof, you can choose a two-layer or three-layer system. A two-layer system has a base sheet and one cap sheet. A three-layer system still has a base sheet and two cap sheets. One is smooth, and one is granular. Three-layer systems are often more durable, more fire resistant, and more energy efficient. Here are the different components.

The first layer of a torch down roofing system is insulation, which is adhered with glue or screwed into the roof deck using plates. This is especially important for flat roofs since heat tends to escape more quickly. The type of roof insulation depends on the material of your roof deck and desired performance.

The second layer of a torch down roofing system is a vapor barrier. Since flat or low-slope roofs tend to collect water and snow, a vapor barrier helps mitigate condensation and moisture problems along the underlayment.

This board is placed over the vapor barrier and supports the torch down roofing membrane.

The base sheet is the first layer of the bitumen membrane. Your contractor can install this a number of ways. Most commonly, they’ll roll out the membrane and use a gas torch with an open flame to melt the rolls to the overlay board. Alternatively, they may use adhesive or another method of heat fusing.

After installing the base sheet, your contractor will install a smooth cap sheet. Again, they’ll use their torch to heat the bottom of the cap sheet and fuse it to the base layer. This forms a watertight seal. At this point, your contractor can stop and you have a complete two-layer system.

To complete a three-layer torch down roofing system, your contractor will apply another cap sheet that has a granulated surface.

Most roofs have features that penetrate the roof (think: HVAC units, chimneys, or vents). In this case, your contractor will install a self-adhering modified bitumen membrane around the features and top it with a layer of metal flashing.

Torch down roofing has a lot of great pros that make it an attractive option for some homes.

White or light-colored bitumen sheets reflect sunlight, which means your home will be cooler and more energy efficient. The darker the color, though, the more heat it absorbs.

Bitumen sheets are very light, weighing just 2 pounds per square foot. But they are also strong, so they’re good at protecting your home from the elements (they do not stand up as well to blunt force damage, however).

Little needs to be done to maintain torch down roofs other than patching holes and clearing off debris. As a result, you won’t have to spend much time or money on maintenance.

Torch down roofing costs start at $7,000, which is less than other roofing options like metal or tile. In comparison, a standing seam metal roof costs $17,000 on average.

Torch down roofs provide an excellent seal against water leaks, and they’re fire-resistant as well—so they offer homeowners peace of mind.

There are a few cons you should be aware of before choosing this roofing.

A torch down roof is best for homes with a slightly angled roof—it’s not an appropriate option for steeply pitched roofs. Most pros recommend it for roofs between .5:12 and 2:12 pitch. If the roof is perfectly flat, the modified bitumen will leak because it’s not made to handle ponding water.

Unfortunately, while this material can stand up well to water, fire, and UV rays, it is more easily damaged by, say, a falling tree branch or hail. This can create holes in the roofing material and eliminate its waterproof barrier. Fortunately, it's fairly easy to patch holes, but it can be a hassle and may affect the appearance of your roof.

Installing torch down roofing takes some skill and expertise, so it's something you'll want to hand off to the professionals. For one thing, you may need someone with a fire operating permit to get the job done, since it involves working with an open flame. Also, a botched installation job can result in water getting stuck between the layers while rolling out the roofing.

It’s important to note that many liability insurance companies don’t cover torch down applications. If you hire a roofer for this job, you should ask for a letter from their insurance company confirming that they have coverage for this type of work.

Contact a roofing professional near you for a consultation and a quote.

Homeowners should look for a lifetime warranty that comes standard with the roofing product and be sure to read the fine print to learn specifically what the warranty covers.

The cost of torch down roofing falls between $7,000 and $14,000, which is in line with the average cost of a roof replacement. That said, if you’re installing a new roof, it’s way more affordable. The typical cost to install a new roof on a home with an angled roof is about $25,000, so torch down roofing might be the way to go depending on your budget. However, keep in mind that other types of roofing last longer.

Labor will make up about 60% of the cost of installing torch down roofing. The roofing materials themselves will be about $1 to $2 per square foot, with labor running twice that. You may have to pay more if you live in a region where flatter roofs are common (such as arid climates), and therefore demand is greater for torch down roofing.

You can protect torch down roofs by coating them to protect from ultraviolet rays, and you will need to reseal it every few years. Other than that, there's not much that needs to be done to maintain the roof aside from clearing off debris regularly and patching any holes that develop.

Fixing a water leak accounts for nearly half of flat roof repairs. Torch down roofs are sealed against water, but they can sustain damage from hailstorms and fallen tree branches, which can lead to leaks. Contact a roofer as soon as possible to have your roof repaired and prevent future damage.

Torch down roofing is just one option for a flat or low-slope roof. Instead, you may choose to install metal roofing, built-up roofing, or a single-layer membrane made out of something like neoprene or ethylene propylene diene monomer (EPDM). It’s important to weigh the pros and cons before you choose. In most cases, torch down roofing works best for:

Roof pitch of 1/12 or less

Climates with extreme temperature changes that crack other roofing materials

Roofs with condensation or moisture issues

Torch down roofing is not suitable for roofs with a significant slope, which is why you’ll typically find it on flat-roofed commercial buildings or multi-story apartment buildings. It’s also not suitable for a DIY project. If you want to install your own roof, pick a different option.

D1 Roofing delivers outstanding service from beginning to end, backed by a strong warranty and expert teams. I highly recommend them for their excellence in meeting and surpassing expectations with unmatched communication. Choosing D1 Roofing was flawless decision

I am really impressed with their timeliness and turnaround. Mitchell came out, and we decided to move forward with their pricing. Our roof was on within a week, and we could not be happier with their team! Amazing company, great prices and honest, dependable craftsmanship. I highly recommend...

Storms Mobile Welding was great to work with. They were prompt, professional and did an overall excellent job on the project. I highly recommend.

We used Unique Hardwood Floor LLC three years ago to work on the floors of a 70 year old home that needed a great deal of work. Some floors needed repairs, some were replaced and others just needed to be refinished. It was a complicated job as they needed to blend the old and the new to...

They damaged multiple items on my property, including a marble slab used as a table top, tried to hide it, and refused to pay or replace. Arrived day one without a ladder to access roof & delayed a day. Left a mess in back yard; didn't wear face masks; no show by owner to property to see damages

While Naaman and Mike were very professional and amicable to work with, there were issues in this project that makes giving a higher rating impossible. We had several communications issues that delayed completion. The roofers accessed the property without communicating with me. Just showed up...

Lyle did a great job removing asbestos shingles from our front porch roof. They worked together with our roofer to make sure that the new roof was able to be installed on the same day that Lyle removed the asbestos shingles.

What a pleasure working with a professional organization that takes pride in its work and wants to ensure customer satisfaction. Out of the several quotes I received for the re-roof, Capps was not the cheapest, but I felt I could trust them to do an excellent job and I was not disappointed....

They did a great job. They checked to determine where the squirrel was gaining entry and set traps to catch it. They removed all of the squirrels (there was only one) and kept the traps in the area with fresh bait to ensure there were no more. They were thorough & effective. Also they...

A wild goose chase. Maybe this is no big deal since this was not an emergency - not a tree that had crashed through my roof - just a nuisance tree that needs to be removed. Even so, it strikes me as quite careless and perhaps a bit rude.

From average costs to expert advice, get all the answers you need to get your job done.

Dealing with a visibly damaged roof or leak? Learn about roof repair costs in Columbus to see how much you’ll need to budget for a permanent solution.

Learn about roof replacement costs in Columbus and what factors are at play to budget accurately and make sure you’re getting a fair price.

A metal roof can defend your home against Ohio’s varying weather conditions. Learn how much a metal roof costs in Columbus, OH.

Courteous homeowners may wonder what the etiquette is when it comes to tipping roofers. Find out if, when, and how you should tip roofers for a job well done.

Painting a metal roof helps it look great and last for decades. Use this guide to learn how to paint a metal roof, whether you DIY the job or hire a pro.

Choosing the right roofing material can help your home stand up to snow, ice, and harsh winds. Learn more about the best roofing materials for cold climates.