Well Water Stopped Working? 5 Causes and Solutions

Evaporate your well water woes DIY style or with a pro

A well-functioning well pump is critical to your well water system.

Problems with your well pressure tank can lead to supply issues.

Routine well maintenance and inspections will prevent future headaches.

If in doubt, call a well repair specialist to tackle problems you’re unsure of.

You’ve turned on your tap and no water is coming out. Initially, it’s an inconvenience but can quickly turn into a real worry, especially if your home’s water source comes from a well. There’s a myriad of reasons why your well water has stopped working—from clogged-up pipes to your well running dry. Discover some of the most common causes of well water problems and whether you can troubleshoot them yourself or need a professional to help.

1. Well Pump Won’t Turn On

A well pressure pump is essentially the heart of your well water system—if it stops pumping, no water will flow from the well to your house. If your pump doesn’t turn on, it may be down to these reasons.

There’s No Power

Check to see if your circuit breaker has tripped, your well pump has blown a fuse, or the well switch near your pressure tank is turned off. If your well pump won’t turn on due to no power, resetting the circuit breaker, flipping a switch, or changing a fuse may be all that’s needed to fix the problem. However, if your well pump is frequently tripping your breaker, it could signal an electrical issue with your pump’s components such as the wiring or motor. Have it checked out with your local well pump repair professional, just to be on the safe side.

Consider installing a battery- or generator-powered backup pump to prevent future well water loss due to power-related hiccups.

The Pump Controller Needs Replacing

Think of the pump controller as your well water pump’s brain. Its purpose is to monitor the flow of water, control the pump to keep water levels consistent and protect the pump against short circuits and overloads. If the controller stops working, it will likely stop the pump.

Power supply issues, faulty connections, or worn-out parts may all play a part in why your pump controller doesn’t work. If a DIY repair doesn’t fix the problem, you’ll likely need a replacement. Replacing a pump controller is among the most common well pump repair costs, and ranges between $200 and $500 depending on the type and brand.

Worn-Out Motor

If your power supply is fine and there’s no issue with the pump controller, the issue may be the well pump itself—particularly, the motor. You’ll need to pull your well pump to check its condition, which you can do yourself with the help of a friend or with the services of a well pump technician.

Once the well pump is pulled, have a look at the splice connection. Most well pump systems have a splice connection at the top of the well and between the pump and the motor. If the connections are corroded, it may just be a matter of getting them replaced. But if your pump’s motor is worn out, it’s likely due to either overuse or age so you will need it replaced. Well pumps last from 15 to 25 years. A well pump replacement costs $1,835 on average.

2. Well Pump Is Constantly Cycling

A well pump that is always running is one of the signs of well pump failure and should be addressed ASAP. Here are some reasons why your pump may be constantly on the go:

Clogged Pipes or Filter

Excessive mineral or sediment deposits in your water pipes can create a buildup of pressure, leading to your well pump constantly short-cycling or switching on and off. Clearing clogged-up pipes or a blocked filter can eliminate the pressure and get your well pump operating normally.

If your well system has a filter and the filter has a bypass valve, open it to see if it stops your pump from short cycling. No bypass valve? Turn the valves around the filter off, remove your water filter cartridge, clean it, and replace it in the filter.

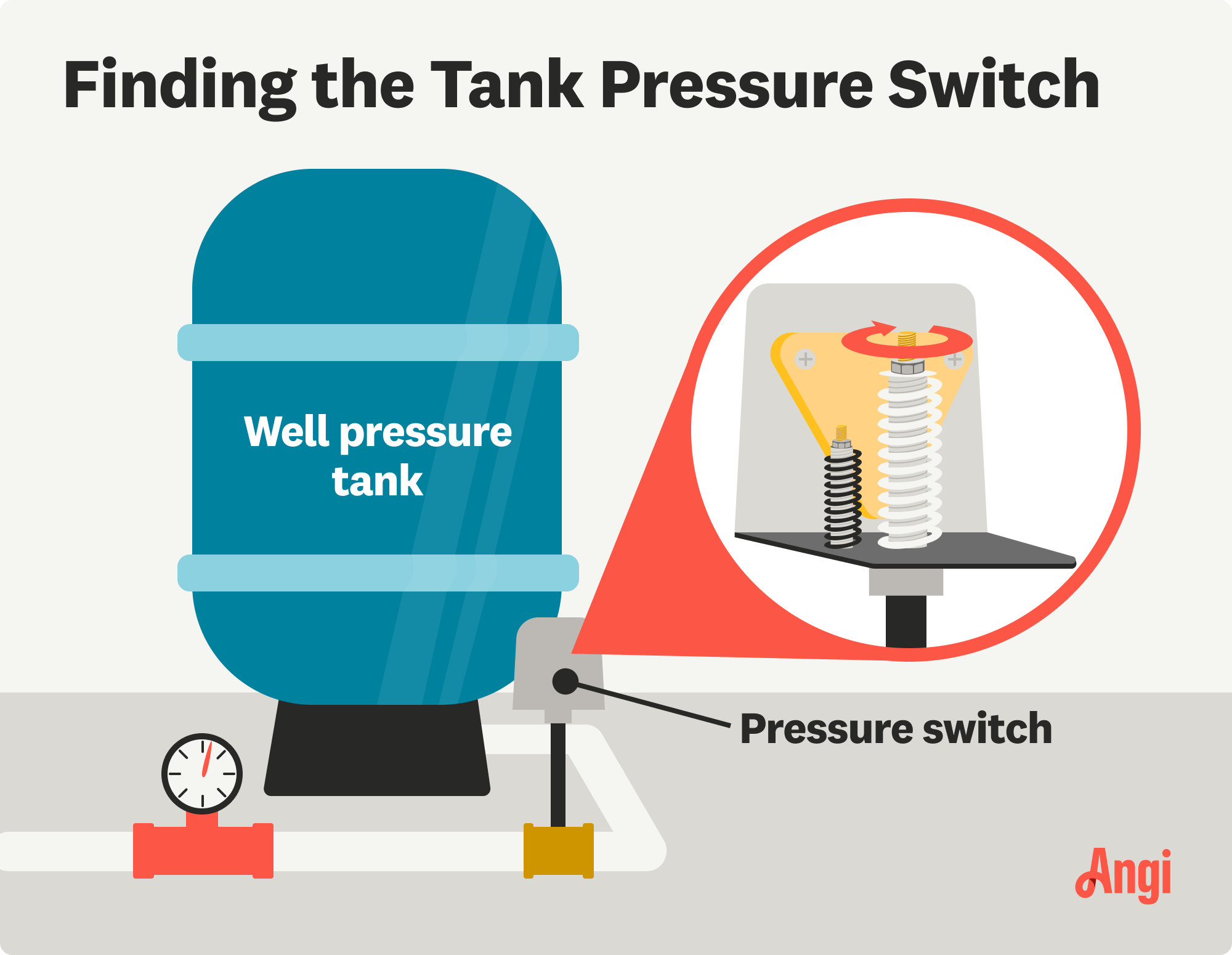

Failing Water Pump Pressure Switch

The well pump pressure switch gauges the amount of pressure in the water system to activate the pump, making it a vital component of your well water system. Some of the telltale signs of well pump pressure switch problems include low water pressure even with the pump running, the pump not turning off or on, or frequent cycling.

If you suspect a failing pressure switch is the source of your well water problems, there are a few things you can do before you call for professional backup. Cut the power to your well pump system and inspect the inside of the switch for corroded contacts. Check for leaks under the switch at the plumbing connection—all it may need is a tightening at the union. Or clean the pressure sensor if it’s clogged with iron bacteria and water sediment.

Not Enough Air in the Water Tank

Insufficient air is a common cause of frequent pump cycling. It is seen most often among older water tanks, non-bladder tanks, and newer models with a damaged bladder.

For non-bladder water tanks, try draining the water and let air re-enter the tank. Or for tanks with a bladder, drain the water and use the air inlet valve to recharge the air in the tank. You can monitor the amount of air in the tank using a tire pressure gauge. Pressure levels are 20/40, 30/50, or 40/60 psi (pounds per square inch)—the low number representing the cut-in value and the high number as the cut-off. The air charge should be 2 psi lower than the cut-in number.

3. Well Is Filled With Sand and Other Sediment

If you notice dirty or sandy water from your taps leading up to your well water not working, it’s a red flag that there’s too much sand or other sediment in your well—which will eventually damage your well pump. One of these reasons may be the cause:

Improper Placement of the Well Pump

Your well pump may be placed too low in your well or it has fallen. In either case, this will cause the pump to draw up sediment from the bottom of the well and need to be repositioned.

When placing your well pump, make sure it’s set level at around 10 to 20 feet above the bottom of the well. This will help prevent any sand, dirt, or sediment from getting sucked into the pump’s intake.

Pump Pressure Is Too High

Sometimes, too much power can be a bad thing. If your well pump has more horsepower than you need, it may be drawing in more than just water. Most residential well pumps require ½ hp to operate efficiently.

To lower the cut-in pressure, rotate the range nut counter-clockwise in your pressure switch. As you adjust, your cut-out value should also lower accordingly. If you’re unsure of how to adjust the pressure switch yourself, call a plumber or well pump repair professional.

If lowering the pressure on your well pump is not an option, you may need to get a less powerful pump installed.

Hole in the Drop Pipe

The drop pipe connects to the well pump and is responsible for carrying water to the well head. A hole in the drop pipe causes air and water leaks, leading to irregular pressure. This causes the well pump to cycle more frequently, pulling in sand and sediment at every intake restart.

The drop pipe can be easily repaired, depending on the size of the hole. You will have to pull the drop pipe from the well in order to inspect it—you can do this yourself, but experts recommend you leave it to the professionals to avoid damaging the pipe. Small holes creating minor leaks are usually fixed with a well liner or repair sleeve. An epoxy putty can also be used, but only as a temporary fix. If the drop pipe is irreparable, you’ll need a new one. Costs range from $135 to $400 per 100 feet.

Old Well Shaft

As a well shaft ages, its structure becomes vulnerable over time due to factors like weather, corrosion, and erosion. If you notice a heavier build-up of sand and dirt in your old well, it's perhaps time for a new one.

Well drilling costs between $1,500 and $6,000 for a new well. Most wells are 100 to 400 feet in depth—the deeper the well, the more you’ll expect to pay. Another option is to have your old well cased, which means well casing pipe is installed around the interior of your well to support its walls. However, casing installation is often just as expensive as a new well.

4. Leaking Well Water Line

All homeowners relying on a well dread a leaking water line. At first, you may not notice it, but if it’s a considerable leak, you could see puddles in the lawn, cracks in your home’s foundation, and a big drop in your water pressure. If this sounds like what you’re experiencing, it’s worth investigating these potential causes.

Wear and Tear

No matter what your water line is made of—plastic, PVC, iron, copper, or steel—it will eventually succumb to the elements of time. If you have an aging water line in your well water system, it’s best to have it professionally inspected by a well repair specialist to determine whether or not your line is salvageable. But, if your line is discovered to have multiple cracks and corrosion, a replacement is your only solution.

Ground Freezing and Thawing

If you live in a chilly region prone to well-below-freezing temperatures, your well water lines stand more of a chance of cracking in the cold. However, this is entirely preventable if you have a water line made of a material to withstand the deep freeze.

Experts recommend using PEX, or cross-linked polyethylene. Not only does this flexible material expand to accommodate frozen water, but it also contracts during a spring thaw. Lines made from copper or PVC plastic tend not to fare well in comparison. Copper loses heat quickly and tends to burst with frozen water. PVC plastic gets brittle at low temperatures, making it prone to cracking in the cold.

5. Low Water Pressure

A sudden drop in water pressure is often one of the main reasons why your well water has stopped working. This could be due to a variety of factors, including these common issues.

Clogged Pump or Screen

Well water containing high levels of iron bacteria can cause sludge, slime, and grime to form on your well pump and well screen. If they become clogged, this prevents water from flowing at an even rate. You can easily clean your well pump and well screen yourself by using a garden hose and a wire brush.

It’s also recommended to hire a well cleaning company to pressure clean your well. This involves using a high-powered compressor, which blows air or water to the bottom of the well to break up any mineral or bacterial buildup. Regular inspections and well water testing may also help control any bacterial overgrowth.

Tank Pressure Switch Is Set Too Low

Check your water tank’s pressure switch—you may not realize it’s set too low. For some, a 20/40 psi doesn’t provide enough water pressure throughout the home. Fortunately, this is an easy fix. First, turn off power to the pump, otherwise you could be electrocuted. Adjust the switch by rotating the range nut clockwise for a higher cut-in pressure. Increase it by 10 psi—for example, if your pressure switch was set at 20/40 psi, adjust the level to 30/50 psi.

Once you’ve changed the pressure level, keep an eye on the pressure gauge so you can monitor the point the well pump cuts off.

Failing Well Pressure Tank

Whether it’s due to mechanical issues or old age, a failing well pressure tank will directly impact the water pressure in your home. This is because a pressure tank holds pressurized air to actively pump well water throughout your home.

A plumber or well repair specialist is best equipped to determine whether or not your pressure tank is beyond repair. If you have DIY plumbing skills, you can save yourself some money and replace it yourself. A new well pressure tank costs around $400 on average. Labor and installation costs between $125 and $200.

Frequently Asked Questions

A water well contractor or well pump repair pro near you is the go-to pro if your well water stops pumping. Well pump repair pros specialize in wells, reservoirs, and other water pumping equipment located outside your home. While plumbers are the experts in indoor waterworks and understand how wells pump water, they may not always have the experience with residential wells that well pump repair pros and water well contractors do.

If the well pump is more than 10 years old, it's worth contacting a well pump repair pro near you and weighing the cost of repairs against buying a new well pump. Pumps can last a long time with regular maintenance, but if your pump is nearing the 10-year mark and starts needing repairs frequently, it’s time to replace it.

Most submersible well pumps last eight to 15 years, depending on the quality, type, and how well they’re maintained. Lower-quality submersible pumps that are poorly maintained will not last very long, but higher-quality pumps can last 15 to 25 years (or even longer). Jet pumps last eight to 10 years.

- How to Check Your Well Pump: Troubleshooting and Fixes

- Common Well Pump Problems and How To Fix Them

- How Much Electricity Does a Well Pump Use? What You Need To Know for Your Home

- Common Well Pump Pressure Switch Problems and How To Fix Them

- How To Increase the Water Pressure From Your Well

- When and How To Test Your Well Pressure Tank

- What’s the Average Cost to Run a Well Pump? [2024 Data]

- How To Get More Pressure From Your Well: Everything You Need To Know

- 9 Tips to Help Increase the Water Pressure in Your House

- 8 Common Problems With Geothermal Heat Pumps