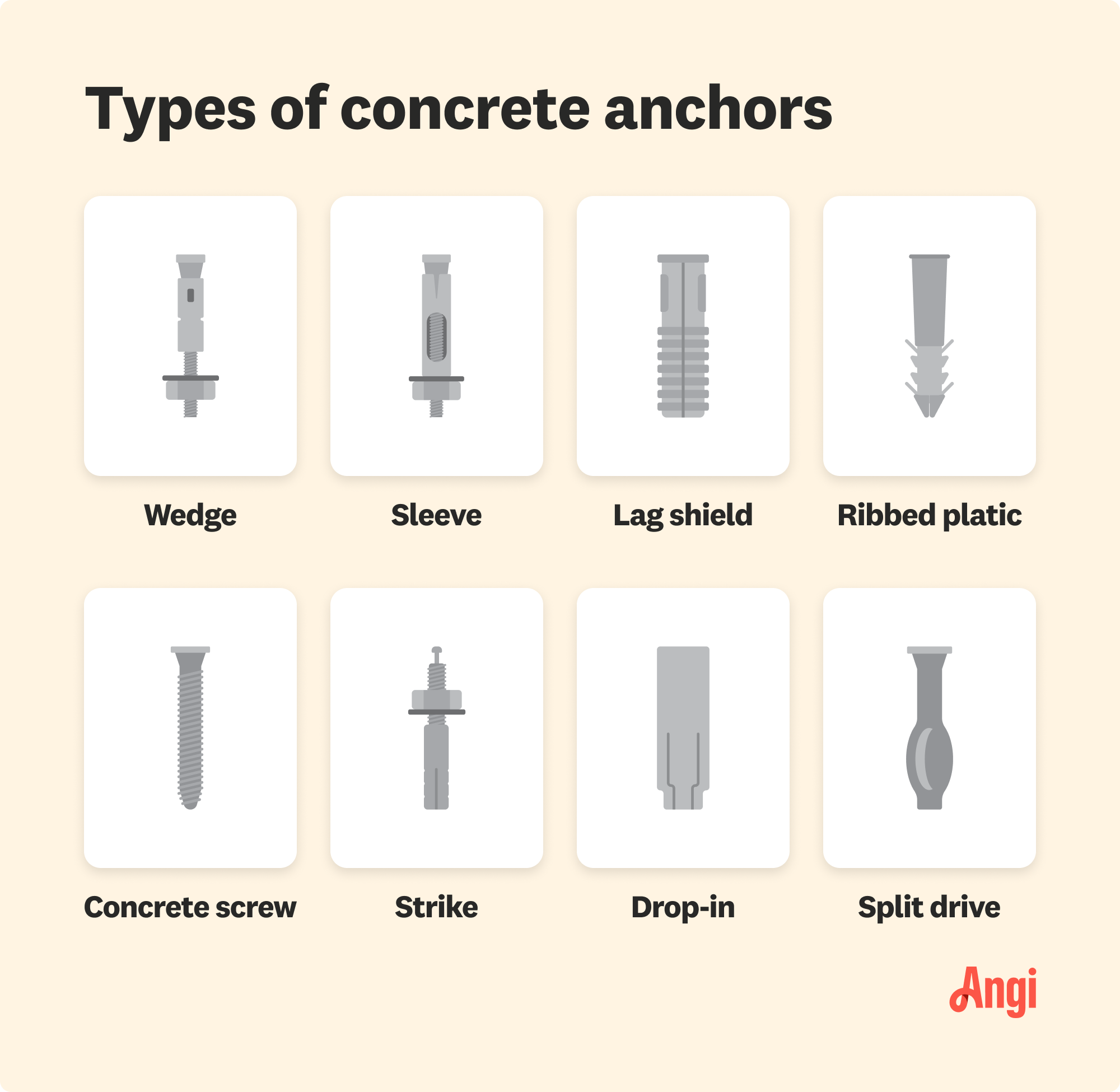

8 Types of Concrete Anchors: Which Is Right for Your Project?

Get the concrete facts about the best types of concrete anchors

Many home projects require you to drill into concrete, but it can be challenging to know what type of concrete anchor will keep everything secure without compromising the concrete. We’ll explore eight common kinds of concrete anchors so you can decide which is best for your project. Knowing which anchor to use is crucial, whether you’re mounting a TV, installing railings on your steps, or putting up new light fixtures.

1. Wedge Anchor

Made of steel and one of the strongest types of concrete anchors (thus optimal for heavy-duty use), the wedge anchor is also one of the most popular choices. Named after its ability to wedge and expand into solid concrete, once you hammer a wedge anchor into place, rest assured it’s there to stay. It’s also corrosion-resistant and relatively easy to insert.

Wedge anchors come in many different diameters and lengths and are also available in zinc-plated steel, stainless steel, and hot-dipped galvanized steel. For this reason, you can use the wedge anchor for a variety of interior and exterior home projects.

| Pros | Cons |

|---|---|

| Can handle a lot of weight | Can only be used for concrete |

| Protects against shearing | May split slab if too close to the edge |

| Permanent once installed | Needs to be cut off |

When to use a wedge anchor: Wedge anchors are ideal for heavy load or heavy shear applications. Since they’re heavy-duty, they can hold structures and wall hangings that weigh 200 pounds and more. But keep in mind that you should only use wedge anchors in concrete blocks and thin-wall or solid concrete. You cannot use them in other materials such as brick, stone, block, or mortar.

2. Sleeve Anchor

Like wedge anchors, sleeve anchors are also made of steel, which make them another solid choice for strong and durable results. As you tighten the sleeve into place, it expands against the base material and creates a firm anchoring. However, unlike wedge anchors, you can use sleeve anchors not only in concrete but also in soft base materials, such as drywall, brick, and hollow blocks.

Although strong, sleeve anchors are best for light- to medium-duty use. Sleeve anchors are available in a number of diameters, lengths, and head styles. You also have the choice between zinc-plated and stainless steel.

| Pros | Cons |

|---|---|

| Can be used in various materials | Limited weight capacity |

| Durable material | More susceptible to shear |

| Requires less drilling depth | Requires a larger diameter hole |

When to use a sleeve anchor: Sleeve anchors are best suited for medium-duty applications, such as light fixtures, metal railings, grab bars, and more. You can insert them into concrete, brick, or block base materials. Available in four head styles and two kinds of steel, you can use steel anchors for a wide range of home construction projects.

3. Lag Shield Anchor

Lag shield anchors (sometimes called lead shields) are another common type of concrete anchors you can fasten to concrete, brick, and block. It’s a screw-style anchor, so you’ll have to pair it with a lag bolt. Lag shield anchors come in five diameters and two lengths for each size.

Short lag shields are ideal for harder masonry materials, which can help to cut drilling time. Long lag shields, on the other hand, are best used in softer and denser base materials to provide greater hold strength.

| Pros | Cons |

|---|---|

| Can be used in various materials | Limited weight capacity |

| Easy installation | Requires separate bolt |

| Resistant to vibration | Improperly spaced anchors can decrease hold |

When to use a lag shield anchor: Lag shield anchors are designed for medium-duty use in concrete, brick, and block materials. Coming in both short and long styles, you can use lag shield anchors in hard and soft base materials. They can reduce drilling time, offer added hold strength, and even maintain a firm hold in areas prone to vibration.

4. Ribbed Plastic Anchor

While concrete anchors are often used for heavy-duty projects, some types are designed solely for lighter home projects, such as hanging a picture or installing a towel rack. Ribbed plastic anchors fall into this category. Ideal for all types of walls but most commonly drywall, these plastic anchor ribs keep the anchor from turning in the hole and expands as you tighten the screw to hold it firmly in place.

| Pros | Cons |

|---|---|

| Effective in drywall | Can only be used for lightweight projects |

| Can be used in other materials | Prone to shear and pullout |

| Leaves a relatively small hole | Not suitable to install fixtures that swivel or move |

When to use a ribbed plastic anchor: Ribbed plastic anchors are optimal for lightweight home projects, such as installing ornamental fixtures, electrical plates, and bathroom fixtures. You can set them in drywall, stucco, tile, and some masonry, but they are mostly used in drywall.

5. Concrete Screw

Like some of the other concrete anchor types we’ve considered, concrete screws come in several different styles and sizes. This means they are extremely versatile, and you can use them for a wide range of applications, such as attaching lumber to concrete or a light fixture to brick.

However, concrete screws work best as a masonry anchor for dry indoor applications. In general, you’ll want to use concrete screws for light- to medium-duty projects in concrete, brick, stucco, or blocks. They are relatively quick and easy to install while also providing a firm hold for the fixture.

| Pros | Cons |

|---|---|

| Easy to install | Prone to corrosion |

| Versatile for different uses | Easy to overtighten |

| Built-in anchor | Can only hold limited weight |

When to use a concrete screw: Concrete screws are best suited for light- to medium-duty projects, like attaching items such as doors, furring strips, and electrical boxes to concrete, brick, stucco, or blocks.

6. Strike Anchors

Strike anchors, also known as hammer-set anchors, are another good option for lightweight applications inside the home. They’re made of steel, coated in yellow zinc, and easy to install using the included pins. Strike anchors are available in various diameters and lengths for different applications.

| Pros | Cons |

|---|---|

| Easy to install | Only for use in concrete |

| Tamper-resistant | Difficult to remove |

| Versatile for different uses | Limited weight capacity |

When to use a strike anchor: Strike anchors are a popular choice for DIYers due to their easy, straightforward installation that doesn’t require specialized tools. You can use them to install lightweight fixtures like electrical boxes, conduit straps or clips, or even wooden fixtures to concrete.

7. Drop-In Anchor

Drop-in anchors use a combination of internal threading and expansion to achieve strong holding power on concrete surfaces. These anchors are mounted flush with the concrete surface and come in diameters ranging from 1/4 to 3/4 of an inch wide.

| Pros | Cons |

|---|---|

| Good for overhead applications | Requires a setting tool |

| Can easily remove bolt from anchor if needed | Can only be used in concrete |

| High weight capacity | Strength depends on size, depth, and concrete composition |

When to use a drop-in anchor: Drop-in anchors are commonly used for overhead installation of HVAC ductwork, sprinkler heads, electrical cable trays, and garage door openers. They’re a good option for fixtures that may need to be removed or replaced, as the bolt can easily be removed without affecting the anchor.

8. Split Drive Anchor

Split drive anchors are one-piece anchors that can be used in concrete and other materials like stone or grout-filled blocks. They are hammered into place and expand once installed, exerting outward force against the base material for a secure anchor. These anchors come in two types of heads—round-head and flat-head—and are best for light- to medium-duty indoor projects.

| Pros | Cons |

|---|---|

| Easy to install | Prone to corrosion |

| Tamper-proof | Limited sizes |

| Permanent once installed | Cannot remove the item being fastened |

When to use a split drive: The most common use for split drive anchors is to install underlayment for hardwood flooring into concrete. The flush head and permanent fastening of these anchors make them ideal for flooring installation.

Factors to Consider When Choosing Types of Concrete Anchors

If you’re still feeling a bit uncertain about how to drill into concrete or choose the best type of concrete anchor for your project, no worries. You can never go wrong hiring a handyperson near you, especially one with concrete experience. They’ll be able to assess your needs and choose the best concrete anchor type for the job, as well as install it correctly.

Consider these factors when deciding which type of concrete anchor is right for your project:

Base material: Not all types of concrete anchors are suitable for the same base materials. You can only use some concrete anchors, like wedge anchors, in certain types of concrete. Other types are ideal for use in base materials, such as brick, drywall, and stone.

Weight of the load: When choosing which type of concrete anchor to use, consider the type of load and how much weight the anchor can withstand. Light- to medium-duty anchors can usually hold anywhere from 50–200 lbs. Heavy-duty anchors can typically hold 200 lbs. or more.

Fixture permanence: Concrete anchors are designed to remain in concrete permanently. However, some types can be removed.

Concrete thickness and hole size: These are important to consider when choosing which diameter and length of an anchor to use.

Concrete age: If you still have concrete forming in your driveway, it’s too early to think about drilling or anchoring anything into the concrete. You shouldn’t drill into concrete that’s less than 28 days old. Some types of concrete anchors may not work in extremely old concrete, either.

Breyden Kellam contributed to this piece.

- Power Washing

- Greenhouse Companies

- Wood & Pellet Stove Repair

- Vinyl Siding Repair Contractors

- TV Antenna Services

- Ceiling Repair Companies

- Wall Repair Services

- Emergency Handymen

- Countertop Repair

- Vinyl Siding Cleaning

- Furniture Assembly

- Trampoline Assembly

- Carport Repair

- TV Mounting

- Chain Link Fence Repair

- Picture Hangers

- Electrical Handymen

- Handymen Plumbers

- Mailbox Installation

- Treehouse Builders

- Door Refinishing

- Aquarium Services

- Grab Bar Installation

- Caulking Services

- Grill Assembly

- The 5 Best Anchors for Brick and How to Use Them

- 7 Types of Drywall Anchors and What They’re Used For

- Unlocking the Advantages of Concrete: Why It’s the Ultimate Building Material

- 17 Types of Concrete and How They’re Used

- How to Dispose of Concrete 5 Ways

- How to Clean Concrete Indoors and Outdoors

- How to Break Up and Remove Concrete

- 9 Tips and Tricks for Beginners Working With Concrete

- Can You Pour New Concrete Over Existing Concrete?

- 6 Concrete Maintenance Tips to Extend Its Longevity