Everything You Need to Know About a Garage Door Cable Diagram

Your garage door should be a smooth operator

The two types are torsion springs and extension springs.

The cable in a garage door opener lifts and lowers the door.

Always hire a garage door pro to replace or repair cables.

If you've ever wondered how a garage door opener works, you’re not alone. The good news is that your garage door cable diagram can help you understand how your garage door opener functions, so you can know whether to repair or replace a part if something goes wrong.

There are two primary types of garage door cable systems: tension spring and extension spring systems. While each uses cables, the spring operation that allows the parts of a garage door to run smoothly varies. Let’s take a look at how they work.

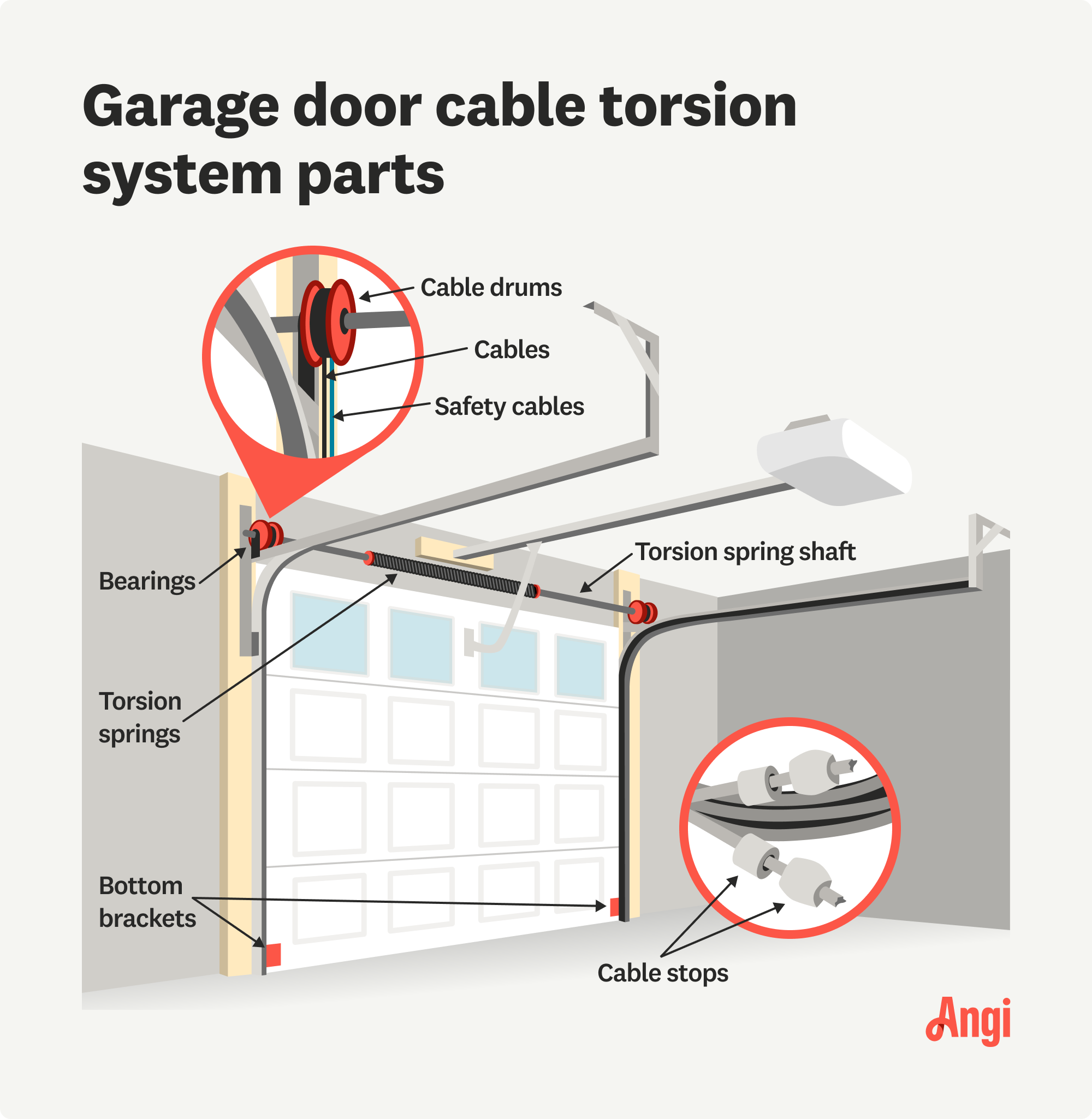

Parts of a Torsion System Garage Door Cable

A garage door with a torsion spring system uses strong springs mounted above the door to lift and lower it smoothly. This type of system is known for its durability and skill at handling heavier doors, such as sectional garage doors.

Torsion Springs

Positioned horizontally above the garage door, torsion springs store mechanical energy and exert force to facilitate the smooth lifting and lowering of the door. The springs contribute to the durability and reliability of the garage door system and are a key element in supporting the door's weight and maintaining its proper functioning over time. As the door moves, the cables wind and unwind around cable drums, guided by the torsion springs for controlled and secure movement. The torsion spring is designed to provide balance and control, preventing the door from slamming shut or rising too quickly.

Torsion Spring Shaft

The torsion springs wind around the torsion spring shaft. When the door is closed, the springs are under tension. As the door is opened, the tension in the springs is released, assisting in lifting the door. The torsion spring shaft maintains balance and stability in the garage door system, ensuring that the forces exerted by the springs are distributed evenly for safe and efficient operation.

Bearings

Bearings are strategically placed components found at both ends and sometimes in the center of the torsion spring shaft. They facilitate the smooth rotation of the shaft as it winds and unwinds during the door's operation. These bearings, often made of steel or nylon, reduce friction and ensure the torsion spring system's efficiency.

Cables

The cables in a torsion system are situated on each side of the garage door. The cables run from the bottom brackets of the door, extending to the cable drums mounted on the torsion spring shaft. As the door opens or closes, the cables wind and unwind around the cable drums, guided by the rotational movement of the torsion spring shaft. This coordinated action assists in lifting and lowering the garage door in a controlled manner to provide stability and balance.

Cable Drums

The cable drum is positioned on the torsion spring shaft and functions as a winding mechanism for the cables. As the door opens or closes, the cables wind or unwind around the cable drum, facilitating controlled movement. The cable drum's rotation is synchronized with the torsion spring shaft, allowing it to wind the cables and store tension when the door is closed. As the door opens, the tension in the cables is released, aiding in the smooth and balanced lifting of the door.

Bottom Brackets

The bottom brackets in a torsion garage door cable system are located at the base of the garage door and serve as anchor points for the cables. These brackets securely hold the ends of the cables and are attached to the bottom section of the door. As the door operates, the cables are wound or unwound around the cable drums. The bottom brackets maintain the alignment and tension of the cables, contributing to the stability and controlled movement of the garage door. Proper installation and secure attachment of the bottom brackets are essential for ensuring reliable and safe operation.

Cable Stops

The cable stops in a torsion garage door cable system are positioned strategically along the cables to prevent them from slipping out of the bottom brackets. These stops act as a fail-safe to prevent the cables from disengaging to maintain the structural integrity of the garage door system.

Safety Cables

Safety cables are additional cables designed to run through the torsion springs, providing an extra layer of safety in case spring breaks. These safety cables are installed parallel to the main lifting cables and are anchored to the bottom brackets. If a torsion spring fails, the safety cables prevent the broken spring from causing harm by controlling its movement.

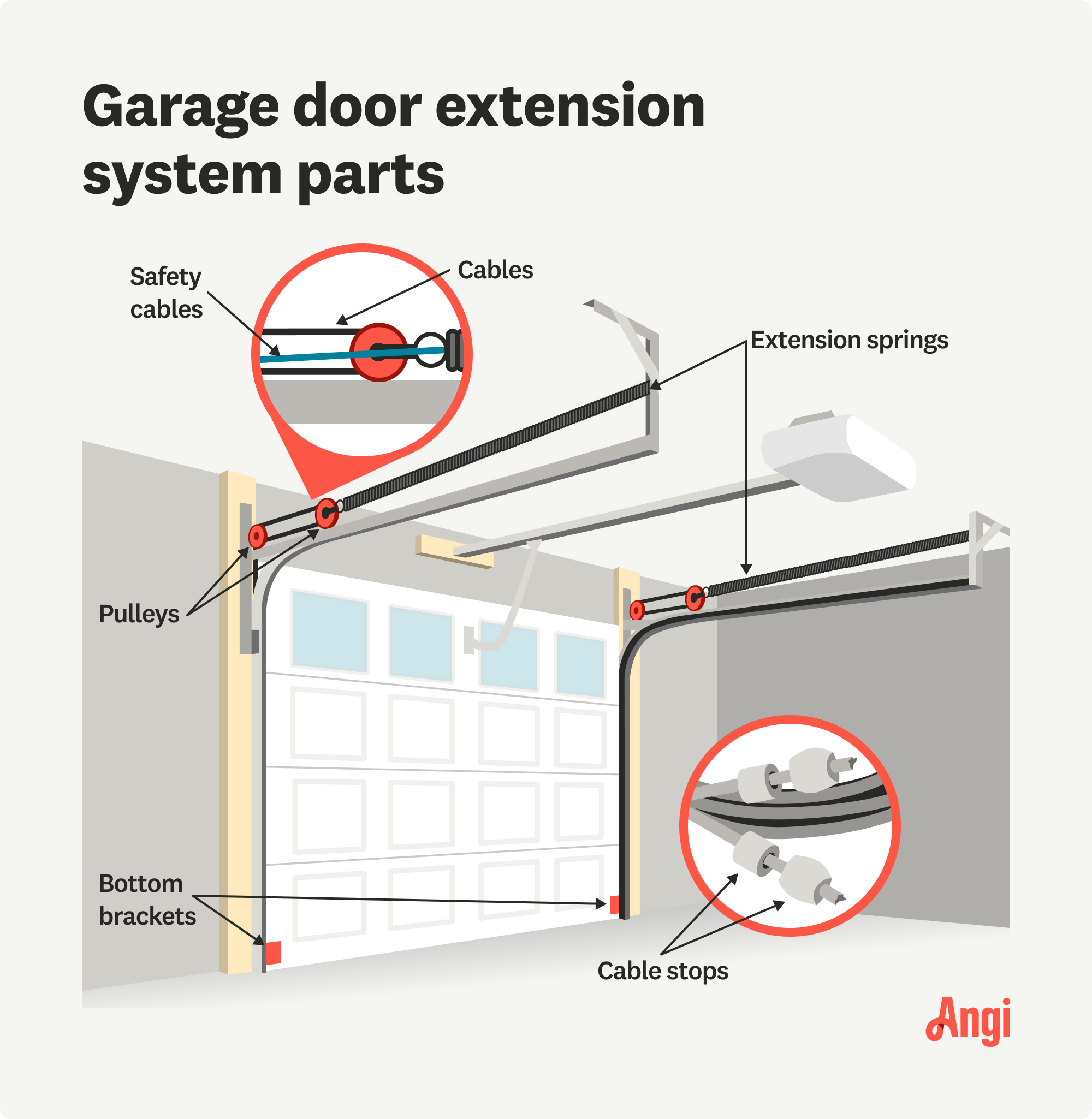

Parts of an Extension System Garage Door Cable

Extension spring system garage doors use springs that stretch and contract to assist in the opening and closing of the garage door. This type of system is often chosen for lighter garage doors.

Extension Springs

Extension springs are parallel to the horizontal tracks on both sides of the garage door, extending and contracting to facilitate the door's movement. The springs are attached to safety cables that run through the garage door extension springs. As the door opens, the extension springs stretch, storing energy, and then contract as the door closes, providing the necessary force for smooth and controlled movement.

Pulleys

In an extension garage door cable system, pulleys contribute to the door's smooth operation. Positioned at the top corners of the door's vertical tracks, pulleys guide the extension springs and cables as the door opens and closes.

Cables

In this system, cables are responsible for transmitting the force generated by extension springs to facilitate the controlled movement of the door. These cables are attached to the bottom brackets of the garage door and run through pulleys positioned at the top corners of the door's vertical tracks. As the extension springs stretch and contract during the door's operation, the cables transmit the resulting force, aiding in the smooth lifting and lowering of the door.

Bottom Brackets

The bottom brackets securely anchor the cables and are attached to the bottom section of the garage door. The brackets maintain the alignment and tension of the cables for stability and controlled movement throughout the door's operation.

Cable Stops

To guarantee the safe and reliable functioning of the door, cable stops secure the fastening of cables to the bottom brackets. The stops are a vital safety measure placed strategically along the cables to prevent them from dislodging from the bottom brackets.

Safety Cables

Safety cables run through the extension springs as extra protection for garage door operation. The cables are installed parallel to the main lifting cables to safeguard spring breakage, should it occur. This safety feature prevents the broken spring from flying across the garage, minimizing the risk of injury or damage.

How to Maintain a Garage Door Cable System

Proper maintenance is crucial to help your garage door system work properly and last a long time. Both torsion and extension spring systems have similar maintenance needs, beginning with inspecting the springs themselves. Check for any signs of wear, rust, or imbalance. With extension springs, you'll also want to look for signs of stretching. For a torsion system, the tension should meet manufacturer specifications.

Examine other components, such as the pulleys, cables, cable drums, bearings, and bottom brackets for signs of wear or misalignment. Lubricate all moving parts to reduce friction and test the garage door's balance by disconnecting the automatic opener and manually opening the garage door and closing it halfway. If the door does not stay in place, it may indicate an issue with the springs or balance that requires adjustment.

For each type of garage door cable system, it's important to adhere to the manufacturer's guidelines and specifications for each. Professional garage door technicians can provide routine maintenance services, ensuring that the system remains in top condition and addressing any potential issues before they become major concerns. Regular and proactive maintenance means a safer and more reliable garage door system for you and your household.

Cost to DIY Garage Door Cable Repair vs. Hiring a Pro

Repairing a garage door cable can be a complex and potentially hazardous task, so it's always best to hire a local garage door repair technician rather than attempting to do it yourself. While garage doors can vary in weight, they are all quite heavy, and their components, including cables, springs, and pulleys, are under high tension. Mishandling these components can result in further damage, safety hazards, or even complete door failure.

With their skillset and equipment, garage door experts can proficiently and safely identify and fix garage door problems. Their ability to pinpoint the exact issue — such as a worn-out cable or a drum that's out of place — ensures precise repairs. Furthermore, these professionals are equipped to thoroughly examine the entire garage door system, which could reveal underlying issues that may have gone unnoticed.

The average garage door cable repair cost ranges between $5 and $50, while installing new cables ranges between $100 and $500. While the cost may not be incredibly high to repair or replace, it's still best to hire a professional to avoid any unforeseen costs later should a DIY repair or replacement go wrong.

Repairing vs. Replacing Parts of a Garage Door Cable

Deciding whether to repair or replace garage door cables depends on the extent of damage and the overall condition of the cables. When cables show significant wear, fraying, or signs of imminent failure, it's more advisable and cost-effective to opt for replacement rather than attempting repairs. The crucial role of cables in the garage door's proper functioning and the potential safety hazards associated with compromised cables make replacement a safer and more reliable solution. However, minor issues like slight fraying might be repairable, given the age of the cables and the overall condition of the garage door system.

- How to Replace Garage Door Springs for Effortless Opening and Closing

- Should I Repair or Replace a Garage Door Spring?

- Why Your Garage Door Won’t Stay Closed and What to Do About It

- What Are All the Parts of a Garage Door?

- How to Adjust a Garage Door Spring: Bounce Back Before It Breaks

- 5 Warning Signs You Have a Broken Garage Door

- How to Manage a Broken Garage Door Spring

- Garage Door Installation Tips Every Homeowner Should Know

- 10 Garage Door Maintenance Tips for Maximum Longevity

- 8 Reasons Your Garage Door Is Stuck and What to Do