Insulating your attic can massively improve your home’s efficiency and reduce electric bills. Use this guide to find out what attic insulation will cost you.

Maintaining a cozy home is all in the details

Duct insulation, often hidden from view within the depths of your home, plays a pivotal role in regulating indoor temperatures, energy efficiency, and environmental comfort. If you're preparing a project, you'll need to know which types of duct insulation to choose from. Whether seeking optimal thermal control, soundproofing, or cost-effective solutions, understanding the options is your first step toward achieving indoor comfort and efficiency.

Fiberglass duct insulation is a versatile and widely utilized option for insulating residential and commercial ductwork. Made up of delicate glass fibers, this insulation is praised for its affordability and efficiency in conserving energy. The material is flexible for both round and rectangular ducts and comes in various thicknesses and R-values—more on that later.

This insulation material can be purchased fully wrapped in aluminum or perforated foil, offering superior sound absorption.

| Pros | Cons |

|---|---|

| Low-cost and DIY-friendly | Risk of respiratory and skin irritation |

| Prevents condensation | Can release airborne particles during installation |

| Good temperature control | Loses insulation properties over time |

| Fire-resistant | Not good at soundproofing |

Best for: Budget-conscious homeowners and DIY enthusiasts.

Polyethylene (PE) duct insulation is commonly used to minimize heat loss or gain within the ductwork. It is made from polyethylene foam, a lightweight, flexible, and resilient material applied to the interior or exterior of ductwork. This material could also be a good choice when installing dryer vent insulation that connects to the home's exterior. Of course, this extra ruggedness comes with a slightly higher price tag, making polyethylene a more expensive alternative to fiberglass.

| Pros | Cons |

|---|---|

| Minimizes heat transfer | Expensive |

| Flexible material | Not fire-resistant |

| Resistant to moisture and condensation | Not DIY-friendly |

Best for: Higher-budget projects and homeowners looking to reduce the risk of mold growth or corrosion within ducts.

Mineral wool duct insulation, or stone wool or slag wool insulation, is a high-performance thermal insulation material that can be installed with a sheet metal liner. It’s manufactured from molten rock or industrial slag, spun into fibers, and bound together to form rigid or semi-rigid boards, blankets, or batts. This robust insulation material is known for its exceptional resistance to heat and fire and its ability to provide both thermal and acoustic insulation.

Many people also like that mineral wool is made from environmentally friendly recycled materials. For this reason, mineral wool is considered a top choice when creating an eco-friendly home.

| Pros | Cons |

|---|---|

| Excellent thermal resistance | Expensive |

| Fire-resistant | Rigid and challenging to install |

| Good soundproofing | Not good for tight spaces |

| Resistant to moisture | Has a heavy weight |

| Durable and long-lasting | Can cause respiratory or skin irritation while handling |

Best for: Homeowners looking to maintain consistent indoor temperatures and improve energy efficiency.

To get the best performance out of your HVAC system, you must use the right kind of insulation in your ductwork. Here are the key factors that determine what type of insulation is best for you.

When shopping for duct insulation, the R-value is arguably the most crucial factor to consider. It measures the thermal resistance of an insulation material, indicating its effectiveness in preventing heat transfer. A higher R-value means better insulation properties, which is particularly important for ducts, as they control the flow of conditioned air throughout your home.

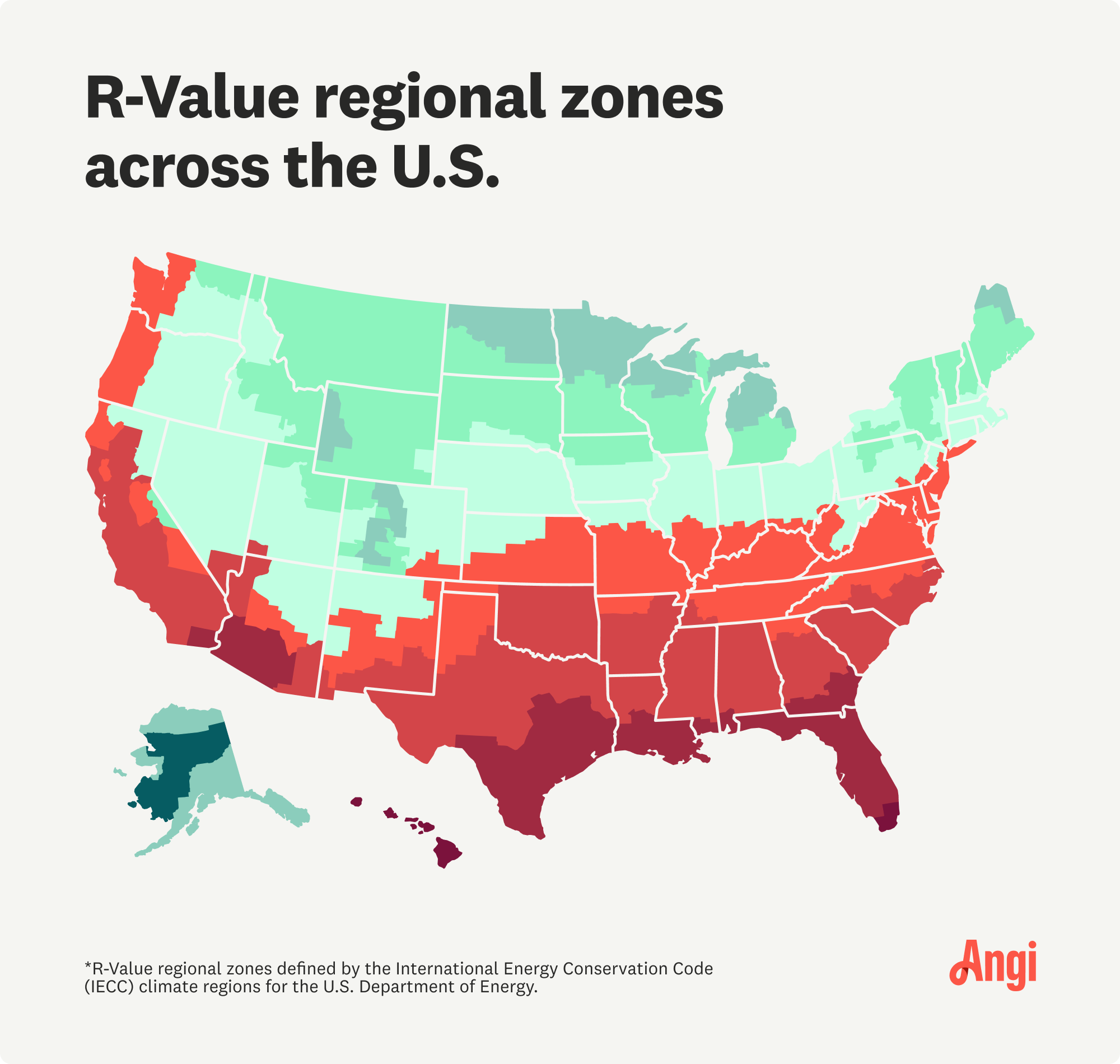

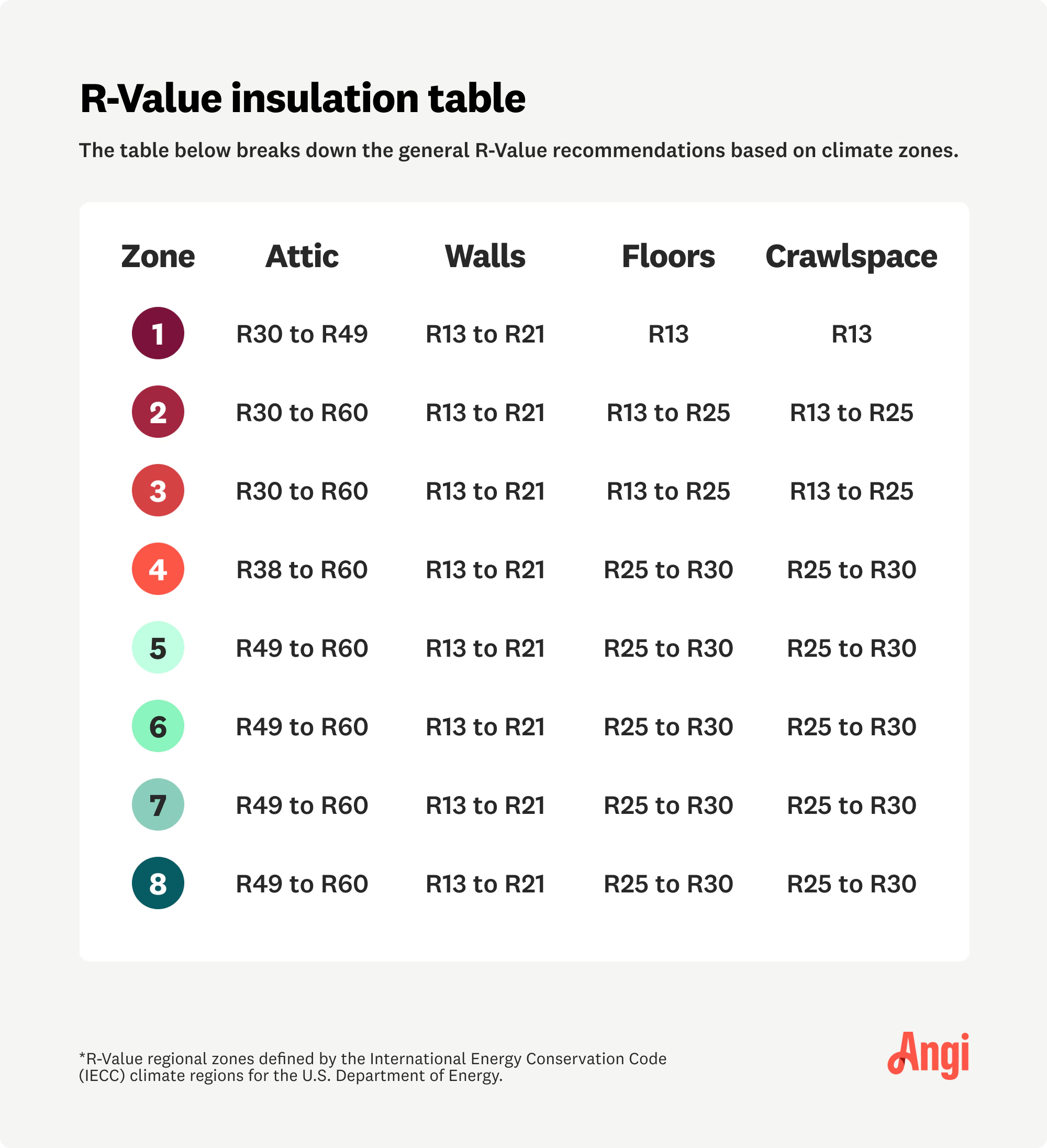

To make an informed choice, first assess your location's climate. Regions with extreme temperatures require insulation with higher R-values.

Each region corresponds with a specific R-Value:

Before selecting ductwork insulation, it’s important to consider how well the material resists moisture and air permeation. Moisture resistance is especially important if you live in a wet, humid area, as exposure to moisture can cause mold growth, corrosion, and reduced thermal performance. Similarly, thermal efficiency decreases when air permeates the insulation material.

Additionally, consider the location of your ducts, whether they are in unconditioned spaces or near external walls, as this affects the necessary level of insulation. Be mindful of local building codes and regulations, which may dictate minimum R-value requirements for your area.

When selecting the most suitable type of duct insulation for your specific needs, budget is another important consideration. Fiberglass is the least expensive choice, but mineral wool's durability may make it more cost-effective over time. As you're considering the cost, remember you need to clean your ducts. Air duct cleaning costs can range between $270 and $500, depending on the size and type of ductwork and insulation you have.

Evaluate the duct system's location and conditions. Polyethylene's moisture resistance makes it ideal for humid environments, while mineral wool provides thermal and acoustic insulation. If fire safety and soundproofing are paramount, mineral wool stands out.

It costs $1,000 to $2,700 to insulate ductwork. However, the average cost for most homes is on the higher end of this range at $2,500. The exact price depends on several factors:

The type of insulation material (fiberglass, polyethylene, mineral wool, etc.)

The material’s R-value (insulation with a higher R-value is more expensive)

How many feet of insulation are needed

The area in which you live

If you need add-on services like duct cleaning or sealing

If you DIY or hire a pro for installation

If you plan to do a DIY installation, consider which one best suits your skill level. Fiberglass is relatively straightforward for DIY projects, whereas polyethylene and mineral wool may require professional expertise due to their unique materials and characteristics. Fiberglass is the way to go if you're looking for an option that offers creative ways to hide ductwork. Ultimately, your decision should align with your specific project requirements and priorities, which may vary. Contact a local duct installer for advice if you have any concerns.

From average costs to expert advice, get all the answers you need to get your job done.

Insulating your attic can massively improve your home’s efficiency and reduce electric bills. Use this guide to find out what attic insulation will cost you.

Wool insulation offers a higher R-value than fiberglass but is more expensive. Use this guide to estimate wool insulation costs for your home.

The cost to insulate a basement varies based on materials, size, and other factors, as well as how much of the work you wish to perform yourself.

Soundproof a room in five simple steps. Learn to soundproof your windows, doors, floors, ceilings, and walls. Beginner friendly.

A radiant barrier can help keep your home cooler without cranking the AC. Learn about radiant barrier problems and how to fix them.

Remove blown-in insulation from your attic safely and efficiently by following this step-by-step guide and prep for your attic remodeling project.