5 Types of Concrete Sealers and How They Work

Seal the deal on the look and longevity of your concrete

Concrete sealers cost an average of $1,500 to install.

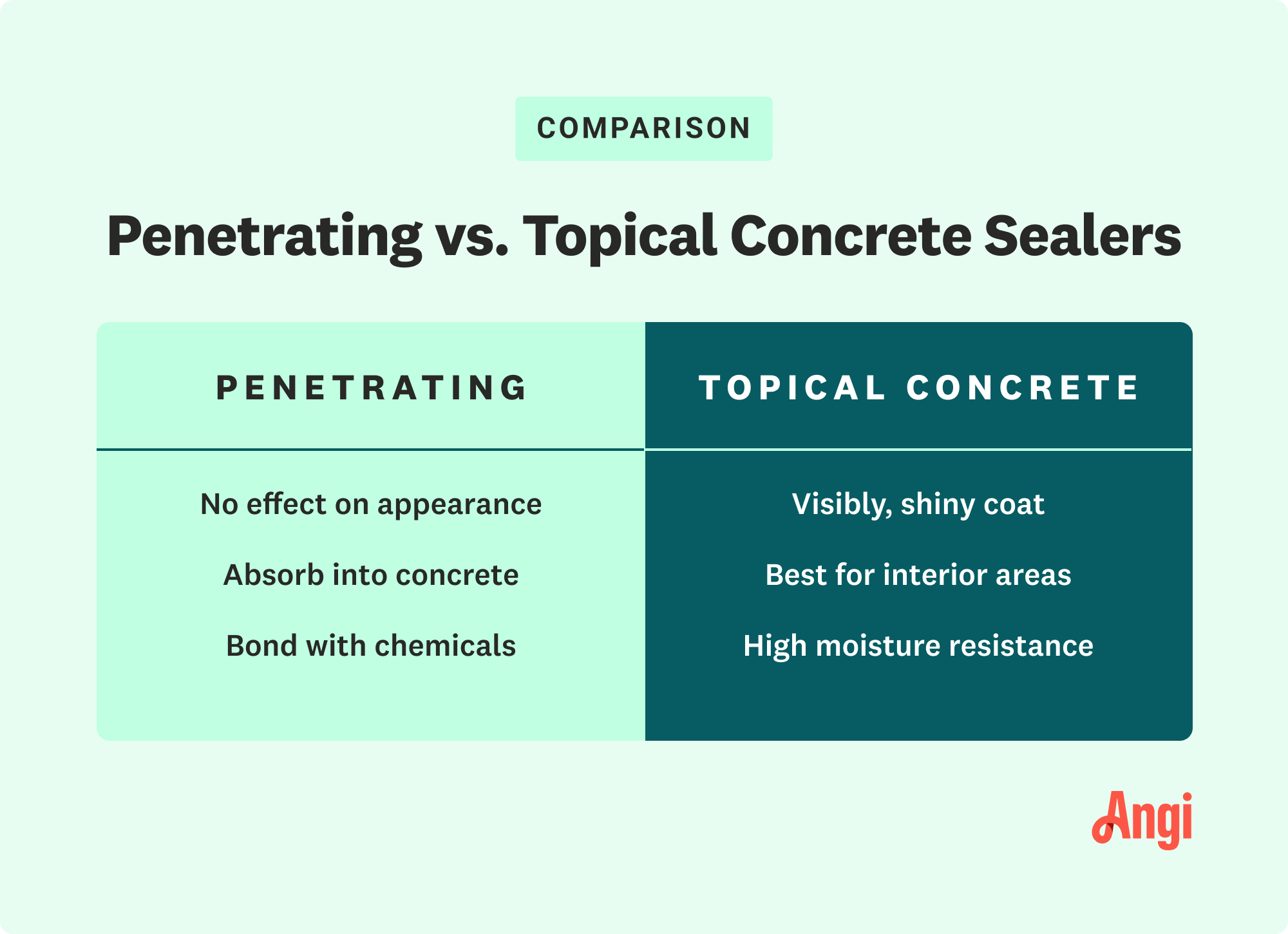

Some sealers penetrate the concrete while others are topical.

Polyaspartic sealers have low VOCs for indoor applications.

You’ll save about $1.50 per square foot with DIY concrete sealing.

Whether you’re looking to protect your new stucco exterior or preserve a brick patio and prevent premature wear and tear, concrete sealers can help protect and extend the life of your concrete. But the sheer number of concrete sealers on the market is enough to make anyone scratch their head. Read on to learn the different types of concrete sealers for your next project.

What Are Concrete Sealers?

Concrete sealers are water- or solvent-based substances that work to strengthen and protect your concrete from harmful water damage, the elements, oil stains, abrasion, UV rays, deicing salts, and more. There are four main types of concrete sealer technologies: acrylic, polyurethane, epoxy, and polyaspartic. Each falls into one of the two main categories for sealers: penetrating or topical, working by either coating the surface of your concrete or penetrating the pores of the concrete and binding with the concrete’s properties.

Penetrating Concrete Sealers

For a sealer that won’t change the appearance of your concrete, you’ll want to choose a penetrating sealer. These sealers absorb into your concrete and bond with the chemicals inside to stabilize and protect the concrete without altering the look of your structure. This is ideal for homeowners who love the way their concrete floor finish looks and don’t want to change the appearance.

Topical Concrete Sealers

On the contrary, some homeowners love the sheen of topical concrete sealers, also called film-forming sealers. These sealers form a protective coat over the surface of your concrete. This makes them ideal for moisture resistance and interior applications, like kitchens and garages, as well as an alternative to the cost of polishing a concrete floor.

You should seal concrete every one to five years depending on the external conditions and level of wear and tear. A masonry contractor can advise on how often your surface will need resealing.

1. Penetrating Concrete Sealers

Let’s break down the four primary types of penetrating concrete sealers: silicates, silanes, siloxanes, and siliconates.

Silicate-Based Sealers

Silicate is a popular type of penetrating concrete sealer because it contains small particles that will seep into the pores of your concrete and chemically react with the lime and calcium to form calcium silicate hydrate. This strong mineral will strengthen the concrete. Popular silicate sealers include sodium silicate, potassium silicate, and lithium silicate.

The downside to silicate-based sealers is they don’t protect your concrete from water damage alone, so they’re not the best option for outdoor sealants.

| Pros | Cons |

|---|---|

| Minimal residue left behind | Not waterproof |

| Raises the pH of the concrete, reducing the risk of damage or cracking | Not ideal for outdoor use |

Best For: Garage, basement, and workshop floors

Silane Sealers

For a water-based sealer, silane concrete sealers are resistant to mold and freeze-thaw damage, making them ideal for outdoor concrete structures in wet or cold climates. These sealers are often found on highways and in commercial concrete. Silane has small molecules, allowing it to penetrate deep into the pores of your concrete, but it requires a high pH level to do the job.

| Pros | Cons |

|---|---|

| Good for outdoor structures | Potential to wear unevenly |

| Penetrates deeply into concrete |

Best For: Driveways and patios

Siloxane-Based Sealers

Siloxane is another waterproof sealer. Unlike silane, siloxane doesn’t need a high pH level to catalyze. However, siloxane does have large molecules, making it less effective at penetrating deep into the concrete. You’ll want to use this sealant for very porous concrete.

Additionally, you can choose a silane- and siloxane-based hybrid. Siloxane and silane go hand-in-hand to reinforce your concrete, as this combination takes the best of both sealants to make an extra effective barrier for protecting your concrete from water seepage, all while strengthening it.

| Pros | Cons |

|---|---|

| Waterproof | Prone to abrasions and wear |

| Can be combined with silane sealers for a stronger solution |

Best For: Driveways and patios

Siliconate-Based Sealers

This medium-size sealant works well for a wider range of concrete surfaces. Siliconate concrete sealers are hydrophobic and help to repel water, mold, salt, dirt, and other debris. They’re also often water-based and emit very little volatile organic compounds (VOCs), making them an environmentally friendly sealant choice.

| Pros | Cons |

|---|---|

| Good at minimizing stains | Not 100% waterproof |

| Low VOClevels |

Best For: Garages, walkways, and patios

2. Acrylic Concrete Sealers

Acrylic sealers are a popular, budget-friendly topical sealer for concrete. This sealer is water-resistant and will help protect your concrete from deicing salt, chemical spills, and—in some cases—ultraviolet damage. You can apply an acrylic sealer to interior and exterior concrete, and it won’t damage your stamped or stained concrete (though it can turn the surface yellow over time).

It’s worth noting that acrylic sealants lack durability and can deteriorate quickly. If you need to reapply sealer frequently, it’s best to remove the concrete sealer every few applications to ensure the new sealer adheres to the concrete solidly rather than existing layers of deteriorated sealer.

There are two types of acrylic sealants: water-based and solvent-based. Here’s how the two compare.

Water-Based Acrylic

Water-based acrylic contains fewer VOCs and is more durable but hard to remove and unsuitable for temperatures under 50 degrees Fahrenheit.

| Pros | Cons |

|---|---|

| Less expensive | Difficult to remove |

| Easy to apply | Doesn’t work well in cold temperatures |

| Low levels of VOC | Requires a lot of prep work |

| More durable than solvents |

Best For: Garages, basements, and other interiors

Solvent-Based Acrylic

Solvent-based acrylic is ideal for outdoor surfaces, recoating, and enhancing the appearance of the concrete, but it contains more VOCs.

| Pros | Cons |

|---|---|

| Enhances color better than water-based acrylic | Higher VOC levels |

| Less prep needed for additional coats | Can bubble and show roller marks |

Best For: Walkways and other high-traffic outdoor areas

3. Polyurethane Concrete Sealers

Polyurethane sealer is one of the strongest, abrasion-resistant topical sealers, making it ideal for walkways and car traffic. Like acrylic sealers, polyurethane sealers come in a solvent-based and water-based form.

You can use this sealer on both interior and decorative exterior concrete—but be warned that this sealant is only moisture-resistant once dry. For this reason, you’ll want to avoid slathering your driveway, walls, or other outdoor structures with polyurethane concrete sealant. Another potential dealbreaker with polyurethane is that this sealer emits high levels of VOCs and is one of the least environmentally friendly sealers.

| Pros | Cons |

|---|---|

| Highly durable | High VOC levels |

| Thicker than other sealers | Must be completely dry before water contact |

| Suitable for interior and exterior surfaces | Non-breathable (vapors can’t escape from the concrete) |

| Greater flexibility than acrylic | Requires sanding for new coats to adhere |

Best For: High-traffic areas

4. Epoxy Concrete Sealers

From your countertops to your floors, epoxy sealers have a way of adding a glossy finish to your concrete surfaces—all while protecting your surface from scratches. But just because you can get a glossy sheen on your interior doesn’t mean you can’t also use epoxy on the floor, too. Some epoxy sealers come with a slip-resistant aggregate for added traction.

Epoxy concrete sealers are susceptible to the sun’s ultraviolet rays and will stain if exposed to the great outdoors, so you’ll want to avoid using epoxy on exterior surfaces. Likewise, opt for a water-based epoxy to avoid VOC emissions in interior spaces.

| Pros | Cons |

|---|---|

| Thicker, longer-lasting protection | Can be slippery without non-slip additive |

| Water-repellent | Vulnerable to UV rays which can cause discoloration |

| Harder than acrylic | Non-breathable (vapors can’t escape from the concrete) |

| Food-safe, can be used on countertops | Requires sanding for new coats to adhere |

Best For: Interior concrete floors and surfaces

5. Polyaspartic Concrete Sealers

One of the newest concrete sealing technologies is a polyaspartic sealer or polyaspartic polyurea. This topical sealer is hot- and cold-resistant, smooth, holds up well to ultraviolet rays, and won’t stain. Polyaspartic sealers also cure in under two hours, don’t bubble in locations with high humidity, and have low VOCs after the application. Since this sealer has a smooth bond, you’ll need to add traction on floors or other walkways.

| Pros | Cons |

|---|---|

| Enhances color better than water-based sealers | Short working time due to quick drying and curing |

| UV- and stain-resistant | Needs non-slip additive for outdoor applications |

| Can be applied at any temperature | Higher cost |

| Tolerates high humidity without bubbling | Can delaminate from concrete that emits moisture vapor |

| Low VOC content | |

| Highly durable and wear-resistant |

Best For: Kitchens and other indoor surfaces

Concrete Sealer Types

| Sealer Type | Applications | Longevity |

|---|---|---|

| Penetrating | Exterior concrete | 5–10 years; up to 25 years |

| Acrylic | Interior and exterior | 2–3 years |

| Polyurethane | Interior and exterior | 4–8 years |

| Epoxy | Interior | 5–10 years |

| Polyaspartic | Interior and exterior | 5–10 years; up to 25 years |

How to Safely Navigate Volatile Organic Compounds

Many concrete sealers contain volatile organic compounds (VOCs), carbon-based chemicals that evaporate at room temperature. When handled improperly, VOCs can be dangerous as they are highly flammable and can lead to short- and long-term adverse health effects, according to the U.S. Environmental Protection Agency, especially in indoor areas that are not well-ventilated.

Some of the most common VOCs found in concrete sealers include xylene and acetone, which are often used to thin down the sealers to make them easier to spray or roll onto a surface. It’s important to wear a respirator approved for working with sealers containing high levels of VOCs.

Also, be sure to apply these sealers in a well-ventilated area and away from heat sources and open flames. You should have no problems if you’re applying sealer on exterior concrete, but your neighbors downwind might be annoyed with the strong smell for an hour or so.

How Much Do Concrete Sealers Cost?

Concrete sealing costs anywhere from $1,250 to $1,750 or an average of $1,500 to install. How much you’ll pay depends on the surface area of your concrete and the type of sealant you choose, with new concrete costing around $1.50 per square foot. High-end epoxy costs more than acrylic sealers. Acrylic sealants may only cost $0.15 per square foot for the material, while epoxy can cost over $2 per square foot.

If your concrete is already deteriorated and cracked, it may be worth comparing concrete slab costs to the cost of preparing and sealing your concrete area.

DIY vs. Hiring a Pro to Seal Your Concrete

You can save around $1.50 per square foot in labor costs with DIY concrete sealing for a garage, driveway, or other area of your home. The installation is fairly straightforward, with the cure time depending on the type of sealant you choose. No matter which sealer you go with, it’s important to know how to clean concrete properly in preparation for sealing it.

Once clean and dry, apply a coat or two of the sealer with a paint roller or sprayer and wait for the sealant to fully dry. But if you’re not up for going the DIY route, you can always call a local concrete flooring company to help with sealing.

Allie Ogletree contributed to this piece.

- How Long Does Concrete Sealer Last?

- How Long Does Concrete Sealer Take to Dry?

- How to Remove Concrete Sealer and Give Surfaces a New Look

- Best Driveway Sealers by Type for Asphalt and Concrete

- How to Seal Concrete Yourself to Help It Last Longer

- How to Clean Concrete Indoors and Outdoors

- Can You Pour New Concrete Over Existing Concrete?

- 6 Concrete Maintenance Tips to Extend Its Longevity

- 17 Types of Concrete and How They’re Used

- 9 Types of Concrete Floor Finishes to Suit Any Home