How Long Do Sump Pumps Last? Is It Time to Replace It?

Swap your sump pump every decade to defend against flood damage

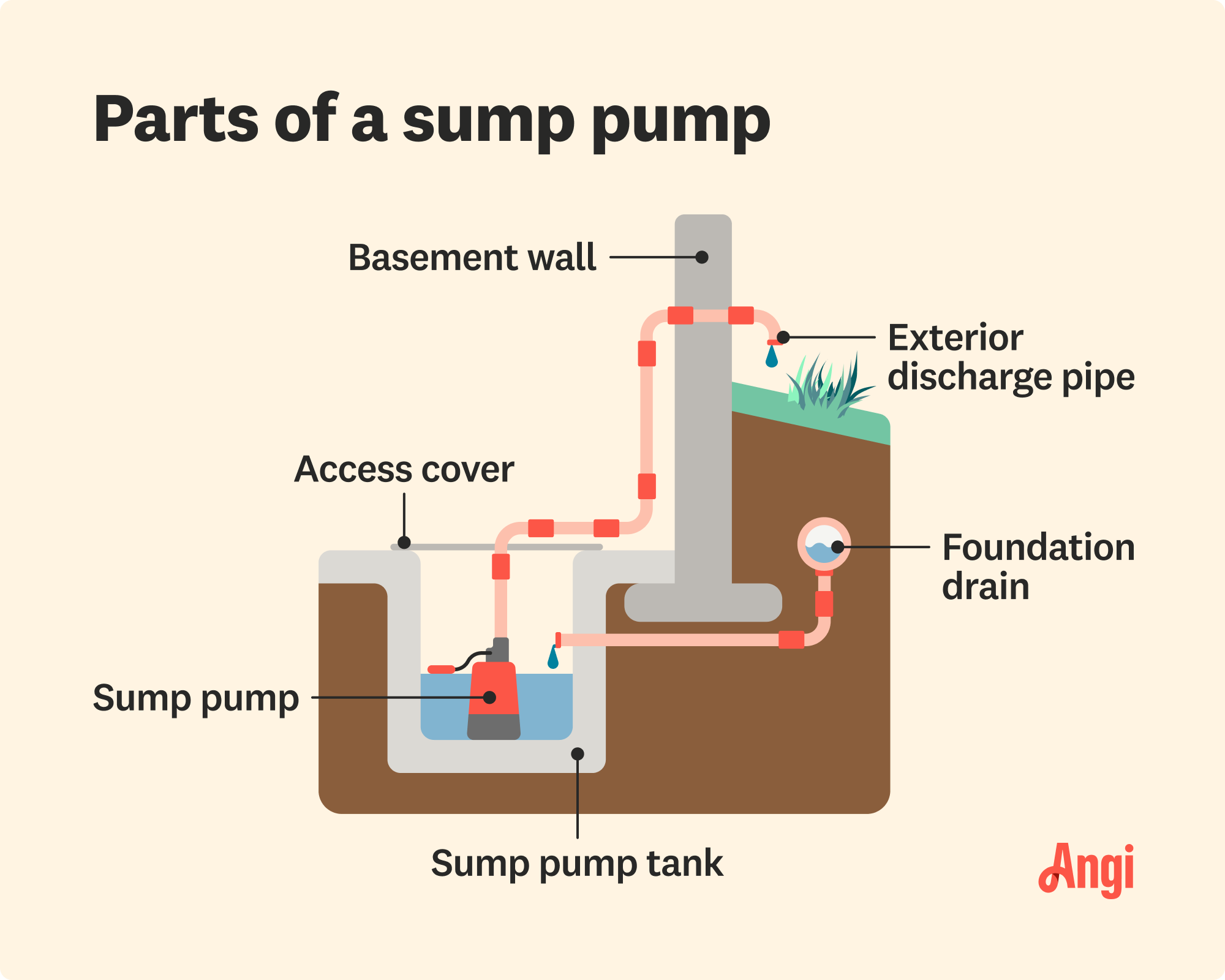

Sump pumps are your final line of flood protection. They are often used in stone basements and designed to let water in or older basements with a history of leakage or flooding. You might also find a sump pump in your crawl space. However, like all other appliances, sump pumps fail after a certain period, and nothing screams more trouble than a failing sump pump when you need it to save the day.

How Long Do Sump Pumps Last?

On average, a sump pump should be replaced every 7 to 10 years with good maintenance. If you’ve never realized there is a sump pump in your basement, chances are it was never properly maintained. In that case, you should hire a professional to inspect the pump so you’re not caught unprepared with standing water in the basement.

Factors Influencing How Long a Sump Pump Lasts

Your sump pump relies on a simple mechanism where a float triggers the motor when the water level is too high. Then, the device begins pumping the water out. A few key factors determine how long your sump pump might last:

Frequency: The more frequently you run the pump, the more wear and tear it gets and the shorter it will last.

Capacity: Sump pumps come in different horsepowers. If you have a smaller, one-third-horsepower pump designed for low or moderate flooding but live in an area with high water volume, you will wear your pump out prematurely.

Cleaning and maintenance: Cleaning and regular maintenance are key. Poorly maintained pumps tend to be short-living.

Signs It’s Time to Replace Your Sump Pump

Many never realize their sump pump is malfunctioning until standing water is in the basement. Next thing you know, you’re spending a fortune on an emergency plumber and a water restoration company.

That’s why you should always look for signs that your sump pump might be dying. Some common signs include:

Visible rust and corrosion: Corrosion and rust around the base, motor, or float are telltale signs that your pump is either undermaintained or too old. These buildups can affect your pump’s normal functionality, clog the motor or float, and eventually cause it to not engage.

Running nonstop: If your pump runs several minutes at a time, it’s either underpowered for the water volume it’s expected to handle or too far from the flooding area, which forces the pump to run excessively to do its job. Make sure your pump has the correct water per hour (GPH) for your needs and is close enough to the flooding zone.

Cycling on and off: Short cycles of on and off are another sign that your pump is dealing with more water than it’s meant to handle. This will eventually burn out the motor, significantly reducing your sump pump’s life span.

Weird noises: If you hear anything other than a low hum from your sump pump, something is not right. Strange noises in sump pumps are usually caused by faulty mechanics, such as a jammed impeller or failed motor bailing.

Excessive vibration: Sump pumps vibrate moderately during normal operation. But if it’s visibly shaking, that might indicate jammed parts or improper installation. Left unattended, the vibration can lead to worse mechanical problems and eventually render the pump inoperable.

How to Increase the Life Span of a Sump Pump

Proper maintenance is the most important step if you are hoping to increase the life span of a sump pump. While it’s best to hire a pro for sump pump maintenance, there are a few things you can do at home to keep your pump in good shape, including keeping the pump upright and avoiding debris from gathering around the pump.

Inspect your sump pump every three to four months. A contractor will check the pump’s physical condition along with Ground Fault Circuit Interrupter (GFCI) checks.

Troubleshooting Tips for Sump Pumps

Most problems with sump pumps are caused by the same reasons: lack of maintenance, rust buildup, corrosion, and overworking. While sump pump repair is a job for the pros, there are useful troubleshooting tips you can follow to give yourself a better idea of what’s going on before reaching out to a contractor.

Sump Pump Won’t Engage

Several reasons can cause your sump pump not to engage or turn on when it’s supposed to. Begin by checking the lid. If the fitting lid is loose, debris and dirt will clog the pump. If that’s the case, pick up an airtight fitting lid, and you can replace it yourself. You should also hire a plumber to thoroughly clean the sump pump if you suspect it might have been jammed. Otherwise, replacing the lid won’t undo the buildups that have already cumulated.

Sump Pump Trips Breaker

A sump pump tripping the breaker is an electric issue. Check your fuse and circuit breaker and make sure they’re the correct size. If your pump sump draws too much energy, it can blow a fuse or trip the breaker. Most sump pumps require an electric circuit capacity that is 15 amps or higher.

Warranties for Sump Pumps

A new sump pump usually comes with a manufacturer’s warranty covering one to three years after purchase. Once that expires, your home warranty policy typically covers sump pump repair and replacement. However, since home warranty policies can vary drastically between carriers and plans, it’s best to check with your provider to ensure your pump is fully covered.

Repairing vs. Replacing a Sump Pump

A new sump pump costs $308 to $748 on average. Minor issues such as buildup cleaning and a loose lid are easily repairable. Generally speaking, if your sump pump is still covered by the manufacturer’s warranty or is less than five years old, repair might be a wiser option.

However, if your sump pump has a severe mechanical problem or is nearing the end of its life span, replacing it completely will save you money in the long run. If your sump pump doesn’t have enough capacity to handle the rainfall, you will also want to replace the basin with a higher horsepower model.

If your sump pump isn’t engaging, it might be clogged with dirt and debris. Check to see if the fitting lid is loose and has been letting debris in. Next, check the float and make sure it’s not obstructed by rust or gunk, which results from insufficient maintenance. Tangled wires or damaged switching systems can also stop your sump pump from engaging.

If you live in areas with severe rainstorms that often cause power outages, a battery backup sump pump will provide additional protection for your home. Frequent outages can also cause electric current surges, which can sometimes burn out the sump pump. A battery backup pump ensures you always have something to keep your basement dry.

A new sump pump installation costs $1,200 to $2,500. If you’re simply replacing the sump pump with all necessary connections in place, you can expect to pay $308 to $748 on average. It is important to have a licensed professional install your sump pump since installation quality can significantly impact your pump’s life span and warranty coverage.

- Gas Plumbers

- Plumbing Repairs

- Sump Pump Installation

- Wood & Pellet Stove Repair

- Shower Repair

- Wood Stove Services

- Emergency Plumbers

- Fire Sprinkler Contractors

- Perc Test Companies

- Toilet Repair & Installation

- Boiler Repair

- Sewer Line Repair

- Faucet Repair

- Main Drain Camera Companies

- Foundation Drain Installation

- French Drains

- Bathtub Replacement

- Subcontractors

- Storm Drain Contractors

- Affordable Plumbing

- Plumbing & Heating Companies

- Bathroom Repair Services

- Sink Installation

- Commercial Plumber

- Barndominium Builders

- Water Line Repair

- Faucet Installation

- Water Line Installation

- Leak Detection