The cost to add plumbing to a detached garage depends on several factors, including the type of plumbing and the garage's distance from your home.

PEX pipes make it easy for plumbing novices to DIY their whole system

PEX pipe is a flexible plastic tubing that has gained popularity in residences.

Flexibility makes PEX easy to work with and ideal for DIY plumbing.

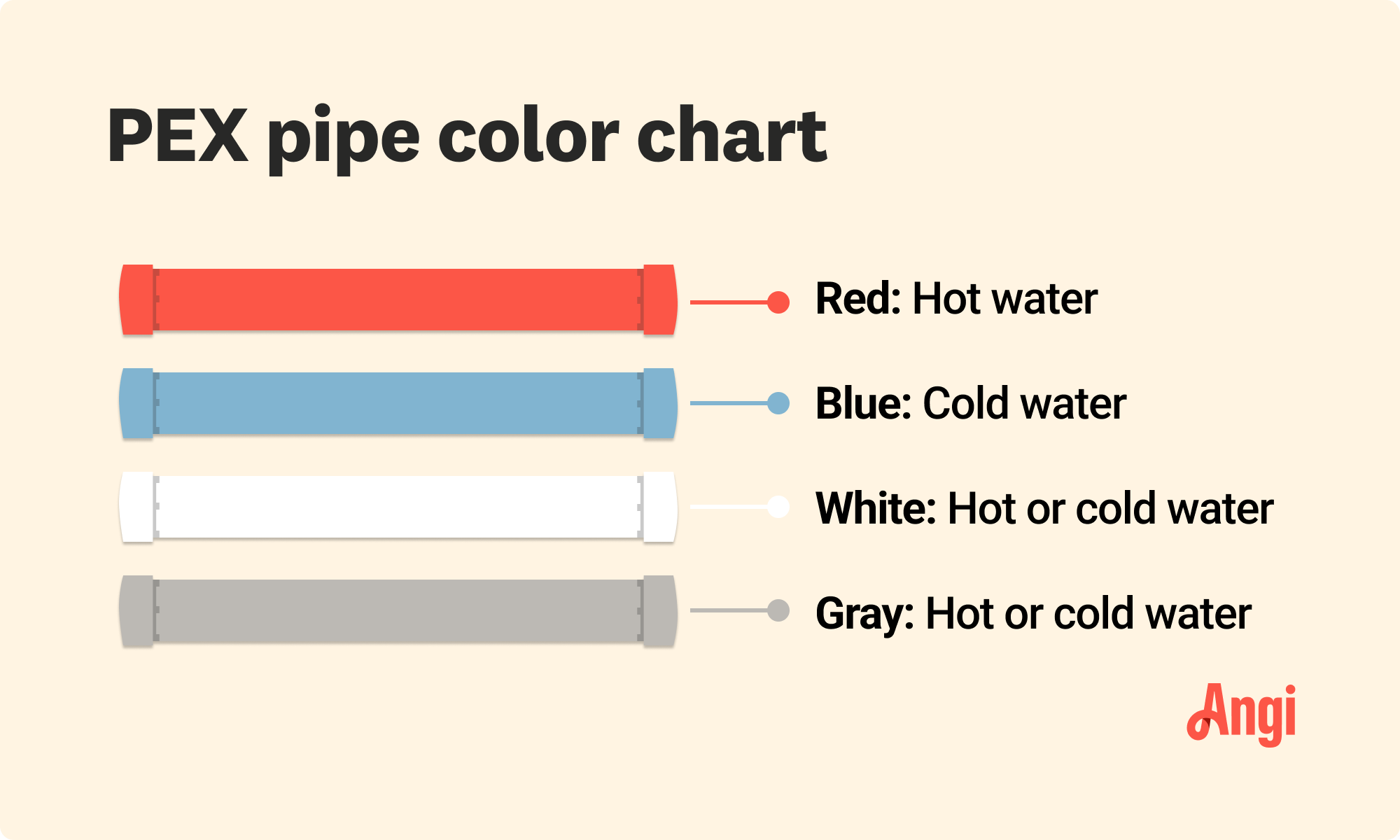

Bright colors make it easy to tell which pipes carry hot and cold water.

PEX won’t crack when freezing or thawing, and water flows through quietly.

You cannot recycle PEX tubing and should avoid using it outdoors.

When you think about the pipes carrying water through your home, do you imagine flexible plastic? If you walk down any plumbing supply aisle, you’ll find it lined with colorful plastic pipes made from cross-linked polyethylene (PEX).

Plumbers and DIYers prefer PEX over traditional copper and galvanized steel pipes because it’s reliable, lightweight, and relatively easy to work with. This means PEX pipe is an easier material to work with for the DIYer attempting to retrofit their plumbing system. Let’s take a closer look at this type of pipe.

PEX pipe is a European invention used in more than 60% of new U.S. home construction today. This is largely thanks to recent manufacturing innovations that allow the plastic to safely carry our more chlorinated drinking water supplies. While there are many types of plumbing pipes, PEX is easy to work with and has multiple uses. DIYers should consider using it for all home plumbing projects and for radiant heat flooring.

PEX is a uniquely flexible material that can easily wind through walls and floors. Plumbers can even use a single length of PEX for each hot and cold water supply fixture. This tactic eliminates the risk of leaks at connection points and is often called “home run plumbing.” With traditional metal pipes, it wouldn’t be possible.

If your home already has metal pipes, you can slowly have PEX spliced in whenever a pipe needs to be fixed. And if you’re having your plumbing system built from scratch, using PEX pipes throughout it can simplify the system.

With PEX, you may be able to fix a leaky pipe without calling in a pro. But if you’re new to DIY or plumbing, hire a local plumbing repair pro to do the job. Even with the flexibility of PEX, plumbing work is complex, with dangerous consequences for mistakes such as severe water damage to your home. In many states, you’ll need a license to add or replace home plumbing.

If you’re tired of freezing your bare feet on the bathroom tile every morning, consider radiant heated flooring with PEX. Hello, toasty toes.

In hydronic systems, PEX tubing embedded in flooring distributes hot water throughout the floor and radiates heat. Radiant floor heating is one of the best ways to heat any space, saving you up to 30% on your current heating costs.

To retrofit a floor with a PEX pipe for floor heating, pros may work from below by fitting tracks for the tubing in the floor joists exposed in your basement. Second-floor installations are trickier and may involve pulling up existing floors to make room for the new heating system. Once it’s in place, you can have a new flooring surface installed on top.

Next to PEX pipe, PVC is the next most popular stand-in for copper pipes. PEX and PVC pipe have many similarities, but some differences that set them apart:

Life span: PEX pipes last about as long as copper pipes, about 40–50 years, whereas PVC pipes last as long as 70 years.

Cost: PVC is affordable at most hardware stores and costs less than PEX piping, which is harder to find but costs about one-third as much as copper pipe.

Recyclability: If sustainability is an issue you care about, PVC pipes are more recyclable than PEX pipes, meaning they’re kinder to the environment.

Flexibility: PEX pipes are the ultimate in flexibility. You can shape and adjust them as needed, and they work well with most other types of pipes if you’re only replacing a section of piping.

| Pros | Cons |

|---|---|

| Affordable | Not recyclable |

| Long life span | Can’t use outdoors |

| Resistant to corrosion |

There are plenty of reasons why DIYers love working with PEX pipes, including their flexibility. However, there are a few drawbacks to consider.

Quiet

Inexpensive

Color-coded

No soldering needed

Resistant to corrosion

With PEX pipes, you won’t have to worry about the spooky creaks that metal pipes make. Water flows through PEX without a peep.

As mentioned earlier, PEX pipes are easier to work with and more accessible for DIYers because they’re fairly inexpensive—PEX pipes are typically one-third the cost of copper pipes—and their color-coding system makes it easy to know which pipe goes where. You also won’t need to solder to put them together, so don’t worry about purchasing a soldering iron.

Unlike metal pipes, corrosion isn’t a concern with PEX. As corrosion can lead to leaks down the road, that means PEX pipes are a durable plumbing solution. They will last an average of 50 years.

Not recyclable

Not suitable for outdoor use

Green-minded DIYers beware: PEX isn’t recyclable. The material doesn’t melt like other plastics do, which poses a major recycling challenge. But it can partially make up for that with its long life span.

PEX isn’t suitable for outdoor use, as exposure to sunlight can damage it. Ultraviolet rays cause the material to break down quickly. If you accidentally leave PEX outdoors ahead of a plumbing project, you’ll end up with dried and cracked tubes in a month or two.

The several types of PEX piping differ in how they're made. When browsing PEX at your local home improvement store, you'll find rolls of tubing labeled A, B, or C, depending on the process used in manufacturing them.

Manufactured using peroxide, PEX-A is the most flexible type of PEX tubing, making it especially easy to work with, even for DIYers. It expands more than the other types and resists cracking when temperatures drop and water freezes. However, it comes at a higher cost than the other types at $3.50 to $7.50 per 10 feet.

Manufactured using a moisture-cure method, PEX-B is slightly stiffer than PEX-A. This aspect makes PEX-B a little trickier to work with but is still highly resistant to cracking when water freezes. It also comes at a lower cost of $2.50 to $5.50 per 10 feet. PEX-B resists deterioration when exposed to chlorine, so it can effectively carry drinking water in many U.S. households.

PEX-C is the stiffest type of PEX tubing, manufactured using an irradiation method. This rigidity makes it the most difficult to work with since it's prone to kinking and tends to crack when water freezes. Its main advantage is its low cost, $1.75 to $3.50 per 10 feet, making it an economical choice for short repairs of straight piping sections.

If you’ve ever looked at your plumbing system and seen a jumble of colorful pipes, you’ve seen PEX pipes. They come in red, white, blue, and gray, and each color is used differently. Red PEX pipes carry hot water, blue pipes carry cold water, and white and gray can be used for either temperature.

Thanks to the flexibility of the material, there’s little risk of PEX pipes freezing or being damaged by heat. This is why plumbers now use it in water systems for both residential and business properties. But while it’s temperature-resistant, PEX can be damaged in sunlight. Only install it underground (it’s a popular choice for heated floors) or indoors.

PEX is flexible, too—it will spring back into its original shape if you bend or twist it, making fitting pipes together easy. The pipes come in a variety of lengths, so you can always find what you need for both small repairs and a complete plumbing system overhaul.

There are several ways to connect PEX pipes, with push-fit being the easiest.

This method is one of the most common ways to connect PEX pipes. With this connection method, copper or brass rings enclose the end of two pipes to connect them and you’ll use a special PEX crimping tool to secure each one into place.

You’ll need a special PEX expander tool (essentially a heat gun) to use this expansion method to connect PEX pipes. Use the tool to heat and stretch the diameter of the tube, then insert the end of a fitting. As it cools, the tube will contract and shrink to its original size to create a seal around the fitting.

This is the easiest (and quickest) way to connect PEX pipes, so it's a popular practice among DIYers. While you won’t need to purchase tools, you’ll want to ensure you get push-fit specified PEX pipes in order for this to work. Push the PEX into a fitting by hand and the small teeth on the inside of the fitting will hold it into place.

Like with the crimp method, the stainless steel clamp method involves tightening rings around connections. You'll slip a stainless steel ring over the PEX tube, insert a fitting, then use a ratchet clamping tool to squeeze a tab on the ring and tighten everything together.

This type of connection involves inserting a hollow brass compression tube into the end of the PEX pipe. Then, a compression ring is placed over the pipe and a threaded brass nut is placed on the end. Tightening the brass nut forces the ring and pipe against the brass tube insert to create a seal.

From average costs to expert advice, get all the answers you need to get your job done.

The cost to add plumbing to a detached garage depends on several factors, including the type of plumbing and the garage's distance from your home.

A leaky faucet can lead to costly water damage and a lot of wasted water. Learn how much it costs to fix a leaky faucet based on type, part and labor.

This guide to toilet installation cost covers what you can expect to pay when adding a new toilet to an existing or new bathroom.

If your faucet hasn’t been working like it used to, you might need a replacement. Here’s how to replace a kitchen faucet like a plumbing pro.

This guide will tell you everything you need to know about different types of showerheads, from eco-friendly, low-pressure models to panel systems.

Tee, cross, wye, elbow, coupling, bushing, adapter, union, and more. Know the most common 14 types of pipe fittings and what they are suited for.