Rubber roof costs vary considerably for each project. Learn how factors other than roof size and labor contribute to the total cost.

Roof truss costs for an average-sized home run about $16,500, but range between $7,500 and $35,000, depending on materials, labor expenses, roof pitch, and building type.

The span of the truss, which is determined by your home’s width, is the most important cost factor to think about.

Trusses for more complex roof styles, like a gambrel roof, can cost more than twice as much as a simple truss for a flat roof.

Interior design options, like cathedral ceilings or open attic spaces, require more complex trusses that will drive up costs.

Roofers charge based on complete roofing systems rather than single trusses, so they’ll take your complete project into consideration when drawing up a quote.

Roof trusses cost an average of $16,500, but you could pay anywhere between $4,000 and $60,000, depending on the type of trusses you need, the square footage of your roof, and more. The cost per linear foot for roof truss materials is between $3.50 and $9.25, and you can expect labor costs for the installation to sit between $25 and $75 per hour.

Trusses can be expensive, but they’re the backbone of your roofing system, so they are well worth the investment. In this guide, we’ll explore roof truss cost factors to help you budget appropriately.

Overall, roof truss prices fluctuate due to location, size, and roof complexity. Here are some things that influence the final cost of your roof trusses.

A single roof truss can cost anywhere between $3.50 and $9.25 per linear foot for materials. The measurement in linear feet refers to the span of the truss, which is the width of the roof from end to end.

For a 40-foot span, a single roof truss costs between $140 and $370, while a 60-foot span costs between $210 and $560. The number of trusses you need, which will be based mostly on the length of your home across the roof ridge, will determine your total cost.

Roof trusses often require spacing of 24 inches, so you can divide the length of your home in feet by two and then multiply by the cost per truss to get an idea of your total. You might need additional trusses for overhangs.

| Roof Truss Size | Cost (Materials Only) |

|---|---|

| 20 feet | $70–$190 |

| 30 feet | $100–$280 |

| 40 feet | $140–$370 |

| 50 feet | $170–$460 |

| 60 feet | $210–$560 |

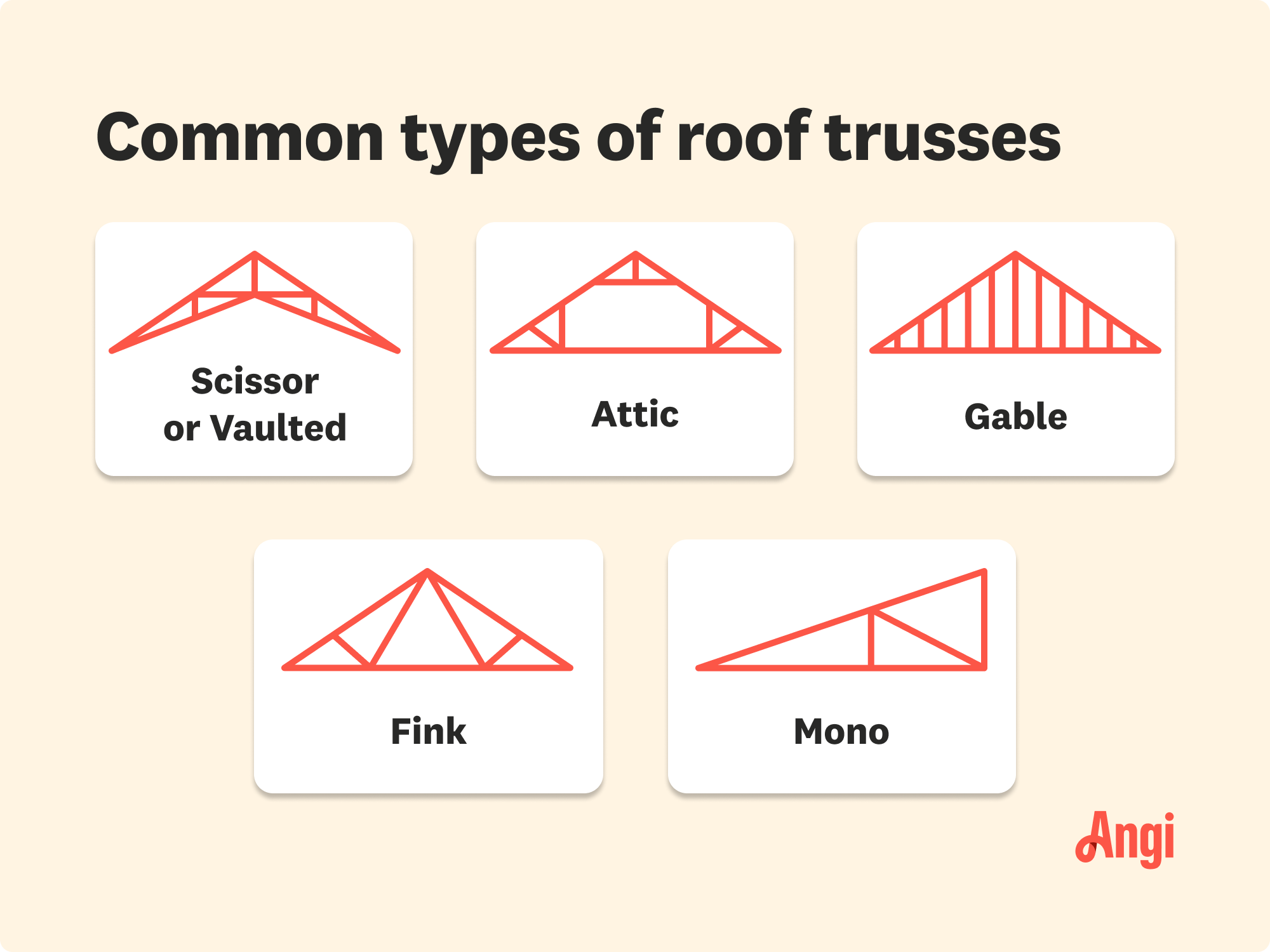

The cost of roof trusses will depend on the type of truss you need for your home. The total depends mostly on the complexity of the truss and the amount of lumber and lumber ties the manufacturer requires for each truss.

Something like a gable truss requires more lumber and ties than an attic truss or fink truss, so it will be one of the more expensive options. Fink and mono trusses use comparatively little lumber and very few lumber ties at the joints, so they’re among the least expensive options.

| Truss Type | Average Cost (Per Truss) |

|---|---|

| Attic | $100–$400 |

| Cathedral | $250–$550 |

| Fink | $120–$260 |

| Flat | $75–$250 |

| Gable | $80–$800 |

| Gambrel | $100–$700 |

| Hip/Hip Frame | $100–$400 |

| King Post | $60–$160 |

| Mono | $60–$450 |

| Raised-Heel | $70–$600 |

| Scissor | $120–$500 |

| Vaulted | $250–$600 |

| Prefabricated | $60–$800 |

The type of building you’re constructing will affect your total roof truss costs. For example, if you’re building a new construction home and plan on installing heavy roofing material, like concrete tiles, clay tiles, or slate, or you’re going to install solar panels, your structural engineer might recommend installing trusses 12 or 16 inches apart on center rather than 24. Putting trusses closer together will add more structural stability and strength to your roof system, but you’ll need more trusses in total, which will drive up material and labor costs.

Some building designs require fewer trusses or more affordable ones based on their use case.

| Building Type | Average Cost |

|---|---|

| New home | $7,500–$35,000 |

| Pole barn | $5,300–$15,000 |

| Garage | $3,500–$9,000 |

| Home addition | $3,000–$12,000 |

The steeper your roof is, the more you’ll spend on trusses because you’ll need more lumber to make up each truss. Steep roofs might also require trusses with more stabilization and supports, as they’ll see heavier horizontal wind loads.

You can calculate the pitch (or angle) of a roof by dividing the number of inches it rises vertically for every 12 inches it extends horizontally. A roof pitch of 6:12 is common, so speak to your contractor or truss manufacturer about how your pitch will affect pricing if it’s much steeper than this.

Truss manufacturers can use wood or steel to make roof trusses, and steel trusses will be more expensive. This is due to the greater challenge of welding the truss components together, as well as the need for additional labor and heavy machinery to lift the trusses into place, which drives up labor costs.

Wooden trusses are the most common option for residential applications, though they have some use in small commercial buildings. They also represent the more budget-friendly option, at $60 to $500 per truss. Wood trusses are easier to install than metal trusses but are susceptible to extreme weather conditions, boring insects, and other issues. They also are not fireproof, so the structural stability of a building will be compromised in the case of a fire.

Metal trusses, which are typically steel, are often found in the commercial and industrial sectors, though certain residential designs require steel trusses. Steel trusses cost $150 to $700 each. They’re more expensive, but metal stands up extremely well to extreme weather and is at no risk of being invaded by mold or insects. It’s also fireproof and won’t warp over time.

| Truss Material | Average Cost (per Truss) |

|---|---|

| Wood | $60–$500 |

| Metal | $150–$700 |

Labor costs to install roof trusses will sit between $25 and $75 per hour, depending on the expertise of the contractors and the demands of the job. Contractors sometimes charge by the square foot, particularly when adding a truss to a new construction. If this is the case, labor amounts to $4 to $10 per square foot, in most cases.

For pre-existing structures, removing the old trusses before installing the new ones adds another $4 to $5 per square foot. Labor costs are generally higher in urban areas when compared to rural sites, due to easier accessibility to job sites.

Roof trusses are heavy and bulky, especially if you need them to span a large distance, and lifting them into place on a second story or higher can be challenging and dangerous without using a crane.

A crane (with operator) costs $300 to $1,000, depending on how long the job takes, though your contractor has likely developed relationships with nearby crane operators to allow for occasional discounts. Pros and amateurs alike also need tall and sturdy ladders, which contractors provide. Buying the ladders on your own costs $100 to $500. Pros also bring various high-powered saws to the job site to cut beams and boards to the specific required lengths and thicknesses.

Most equipment costs will be baked into the total installation cost, although crane rental and operation is a common exception and often shows up as a dedicated line item.

You may pay an extra $100 to $200 for disposal fees for waste when laying down trusses on top of new construction, with prefab trusses being your least expensive option here. The costs climb much higher when disposing of pre-existing trusses. Demolition here costs $4 to $5 per square foot, and disposing of the old trusses costs anywhere from $300 to $1,800.

Roof trusses are built to support the weight of your roofing materials, including insulation, and should be able to handle local snow-load averages. If you live in an area with a higher-than-average snow load, you might require a bulkier truss design or shorter spaces between trusses to add support.

Accounting for high snow volumes or heavier roofing materials like slate could increase the cost of truss construction by around 25%. Talk to your roofer, as they are well-versed with any local requirements to accommodate snow load.

The vast majority of roof trusses are installed with a spacing of 24 inches on center. If your building requires a higher level of stability, pros may recommend spacing your trusses at 16-inch intervals or even 12-inch intervals. This translates to more labor and materials, as it increases the number of trusses the building needs. Count on paying around 50% more for trusses that are spaced 16 inches apart and about 100% more for trusses spaced 12 inches apart.

Roof trusses support the entire roof structure, and installing or replacing one affects load-bearing walls and structural stability. Improper installation can lead to sagging, shifting, and costly roof repairs in the future. By hiring a local roofing pro, you’ll know the job’s done right, protecting your roof’s strength now and in the future.

Roofing stability and strength are not to be taken lightly, and here’s why you’ll want a pro to do the job:

Roof truss experts confirm that your home’s truss design meets the load requirements for your climate and roofing specifications, including snow, attic storage, and solar panels.

Roofing contractors know how to follow structural plans so the roof’s weight is evenly distributed.

They have the right heavy-lifting equipment and experience needed to correctly position trusses.

They’re prepared to deal with hidden framing issues or damage that may be uncovered during the work.

Roofers know how to fasten and brace trusses to prevent them from shifting or failing.

Contractors can coordinate with engineers if your roof design needs modifications.

They will ensure your roof’s sheathing and tie-downs are installed correctly.

Before grabbing your ladder, it’s best not to go on your roof for repairs. Getting up on a roof is challenging and potentially dangerous, so this one is best left to a roofing professional.

Roof trusses can be quite expensive, but there are a few things you can do to keep costs down:

Find the best company to work with. Contact at least three different companies and get estimates. Look at their reviews, read customer testimonials, and review their estimates before making a decision.

Find a reliable manufacturer. Ensuring you have a reliable truss manufacturer will reduce the risk of broken trusses or misaligned components, which would require truss repair. Ultimately, you might pay a bit more for work from a good manufacturer, but you could save time and money in the long run.

Choose your truss type carefully. Some truss designs are more involved and more expensive than others. If you’re building new construction, keep the design simple to keep your costs down, and forgo vaulted or cathedral ceilings or ornate roof designs.

Use pre-fabricated trusses. Pre-fabricated trusses are likely more affordable than custom ones, even if it means paying more for delivery to the job site.

Finish the interior yourself. Installing a roofing system isn’t a job suitable for DIYers, but you can save hundreds or even thousands on your total project costs by hanging drywall on the underside of your trusses and tackling other finishes, like spackle, paint, and trim.

Confirm whether you’re replacing only damaged roof trusses or updating the entire roof structure.

Review your current roof load so your roofer can determine the right type of trusses and spacing.

Ask if an engineer needs to review or adjust the truss design, especially for older homes or additions.

Review the permitting and inspection schedule to anticipate the timing.

If your budget allows, consider discussing other structural upgrades, such as reinforcement for future insulation, ventilation, or solar systems.

Home is the most important place on earth, which is why Angi has helped more than 150 million homeowners transform their houses into homes they adore. To help homeowners with their next project, Angi provides readers with the most accurate cost data and upholds strict editorial standards. We extensively research project costs to develop the pricing data you see, so you can make the best decisions for you and your home. We rely on reputable sources, including the U.S. Bureau of Labor Statistics, academic journals, market studies, and interviews with industry experts—all to ensure our prices reflect real-world projects.

Want to help us improve our cost data? Send us a recent project quote to [email protected]. Quotes and personal information will not be shared publicly.

From average costs to expert advice, get all the answers you need to get your job done.

Rubber roof costs vary considerably for each project. Learn how factors other than roof size and labor contribute to the total cost.

Discover composite roof repair cost estimates. Learn what impacts pricing, how to save, and whether to repair or replace your composite roof.

Raising the roof in your home can add character and intrigue, as well as living space. Use this guide to learn the cost to raise a roof, as there are expenses you may not have considered.

If you’re upgrading your roof with stone-coated steel, you should be aware of the total project cost. Learn what will impact your final stone-coated steel roofing costs.

You may wonder what fascia is on a house. Our guide explains what you need to know about this important part of your roof and what purpose it serves.

What's a cupola? Is it possible to have one on my home? What do they look like? Learn all about the variety of cupolas you can add to your home or barn.