Exposed ductwork can be a smart choice even beyond aesthetics. Fortunately, exposed ductwork costs are relatively low, and easy access keeps repair costs to a minimum.

A compressor puts the squeeze on refrigerant to keep your air nice and cool

A compressor squeezes refrigerant to move it through the HVAC system.

Your AC system needs a functioning compressor to cool your home properly.

Reciprocating compressors are the most common type in residential AC systems.

HVAC maintenance requires the expertise of a trained technician.

A new AC compressor costs an average of $1,200.

Many of us rely on central air conditioning to cool our homes without pausing to wonder how it works. However, if your AC stops working and starts blowing warm air, you'll quickly become familiar with the compressor. A compressor in an HVAC system is key to keeping your house comfortable, so it’s good to know what it does, how it works, the types you might encounter, and how to maintain it.

A compressor is a crucial component of a heating, ventilation, and air conditioning (HVAC) system that is located in the outdoor air handler.

The role of a compressor is in its name. It's the part of the HVAC system that compresses—or squeezes—warm refrigerant gas. This compression raises the temperature and pressure of the gas, allowing it to cycle through the AC system to the condenser, where it cools.

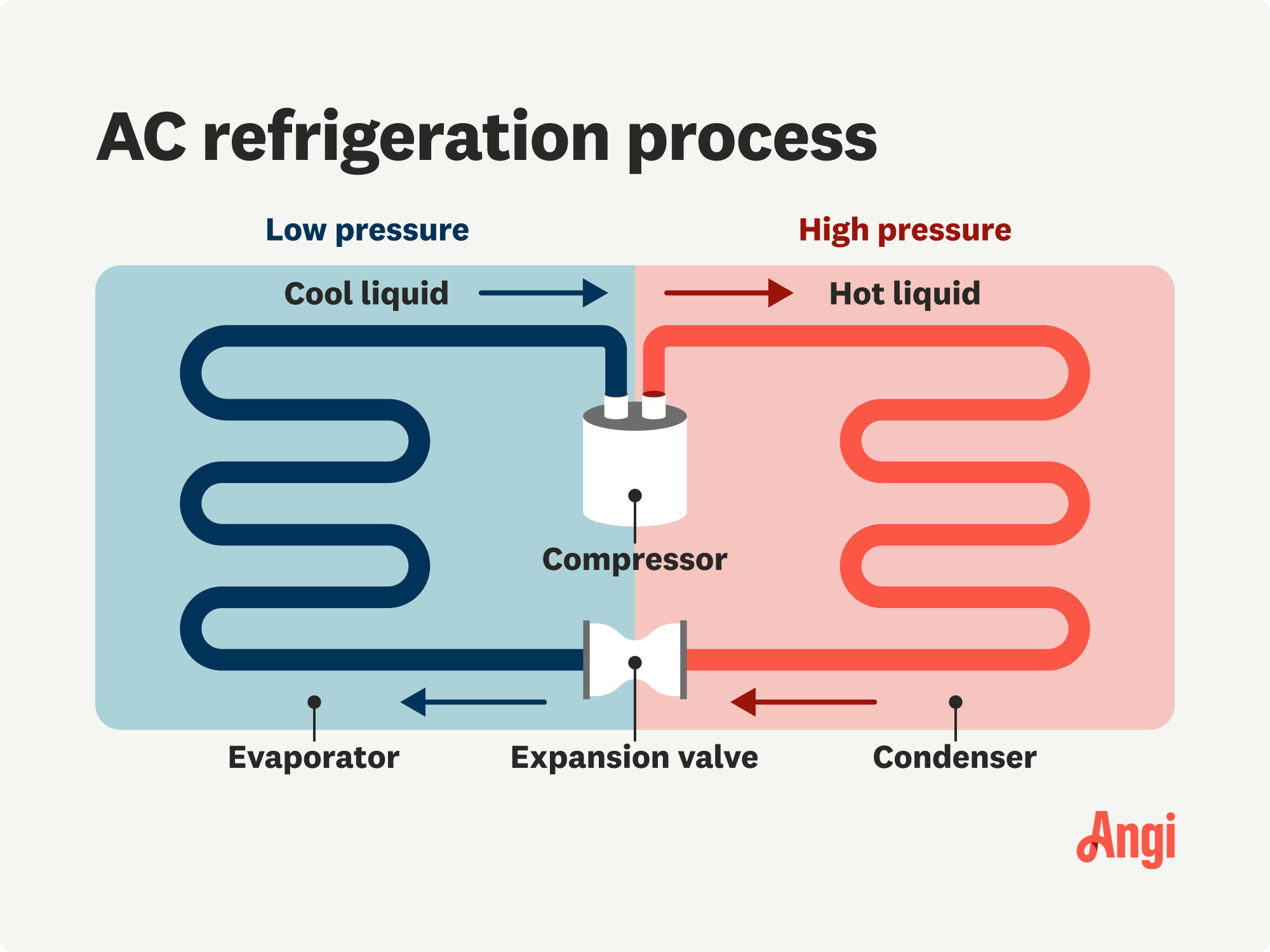

To understand how a compressor works, it helps to know how AC refrigeration works.

Air conditioners remove heat from indoors and carry it outdoors. To do this, the cold liquid refrigerant inside the evaporator coil absorbs indoor heat until it changes from a liquid to a low-pressure gas. That's where the compressor comes in.

The most common type of HVAC compressor is a reciprocating compressor with multiple cylinders. Each cylinder contains a piston, a suction line for taking in refrigerant, and a discharge valve for releasing refrigerant. The compression process is as follows:

The compressor pulls the pistons downward to reduce the pressure inside the cylinders.

This difference in pressure causes the suction line to pull in refrigerant gas.

Once a cylinder is full of gas, the compressor pushes the pistons upward to reduce the space inside the cylinder and increase the pressure and temperature of the gas.

After enough pressure builds up, the heated gas escapes into the condenser, releasing heat outdoors and cooling back into a liquid, ready to repeat the process.

There are five main types of compressors used in AC units. Each uses a different mechanism to compress refrigerant.

Reciprocating: The most common for residential AC, which uses pistons within cylinders.

Rotary: Small, quiet, and ideal for window units. This type uses a rotating blade or shaft.

Scroll: Long-lasting and quiet, but more expensive. It uses a motor and two spiral scrolls.

Screw: Highly efficient and common in commercial AC, this compressor uses rotating screws.

Centrifugal: Expensive and only practical for large AC systems because it uses centrifugal force to function.

The average AC compressor lasts 10 to 20 years, depending on how well you maintain your HVAC system and how often you use it. If your AC is blowing warm air, it may be because your compressor is breaking down and needs repairs.

Running your AC with too little refrigerant can put stress on the compressor and eventually cause it to fail. However, only a licensed pro from a local HVAC service can properly diagnose your AC issue and make necessary repairs.

Schedule annual HVAC maintenance appointments, during which an HVAC technician will check your system's refrigerant levels and adjust them if needed.

The average replacement cost of an AC compressor is about $1,200, though you could pay up to $2,800. Repairing an individual compressor can cost up to $3,000. Because of these high costs, many homeowners opt to simply pay the cost to update an AC system entirely when significant repairs are needed.

From average costs to expert advice, get all the answers you need to get your job done.

Exposed ductwork can be a smart choice even beyond aesthetics. Fortunately, exposed ductwork costs are relatively low, and easy access keeps repair costs to a minimum.

Whole-house humidifier costs vary based on the type and size of the unit, along with other factors. The price might be worth it for people living in dry regions.

Heating and cooling system on the fritz? Discover the factors that go into HVAC repair costs and how you can save money on this crucial home update.

Who do you call to fix a boiler? This easy guide will help you hire the right pro for the job of fixing your boiler.

Are you considering adding a whole-house humidifier to your home? Keep reading to learn the pros and cons of a whole-house humidifier.

No one likes a cold shower or a frigid winter night. Regular boiler maintenance and repair will ensure your appliance stays in tip-top shape. Keep the hot water flowing year-round with these easy tips.