Skim coating drywall is a great alternative to replacement, and is often more affordable. Use this guide to estimate the cost to skim coat walls in your home.

Smooth surfaces on the horizon

Have a drywall installation pro evaluate your project’s needs to identify the best drywall mud to use.

All-purpose compound is the most affordable choice, but depending on the project, you may need to go with a more expensive type, like top compound or quick-setting compound, to get the job done right.

For DIY jobs, all-purpose compound is easy to work with and budget-friendly.

Taping compound is specific to taping drywall joints and will produce the best results.

Top compound is best for the final coat while quick-setting compound works best for repair jobs that need to be done fast.

Drywall mud, also known as joint compound, plays a pivotal role in the transformation of bare drywall panels into beautifully finished walls and ceilings. Whether you're a seasoned DIY enthusiast or a newcomer to the craft, understanding the characteristics and applications of the types of drywall mud will empower you to embark on your home improvement endeavors with confidence and precision. Learn everything you need to know about each of these four products.

All-purpose drywall mud often serves as the primary coat in drywall applications due to its bonding properties, enhancing the adhesive qualities of the drywall tape. As its name suggests, it can also be used for other stages in drywall installation such as bedding, taping, and finishing. Its use is popular with both DIY enthusiasts and professional drywall installers.

| Pros | Cons |

|---|---|

| Widely available | Longer drying time |

| Easy to sand | May shrink during drying |

| Budget-friendly | May require more coats |

| Long shelf life | Can crack over time |

Best for: DIYers and those on a budget

If you’re wondering what hot drywall mud is, it's commonly known as quick-setting or setting compound. Its introduction has revolutionized the process of installing and repairing drywall. With its rapid drying capabilities, this specially engineered compound has significantly impacted project timelines.

| Pros | Cons |

|---|---|

| Quick dry time | Harder to adjust on the fly with fast drying time |

| Needs fewer coats | More costly than standard options |

| Great for small repairs and patches | Tough to DIY |

| Doesn’t shrink as much during drying | Heavy |

| Strong adhesion | Limited variety |

Best for: Timely projects and repair work

Taping drywall mud is specifically formulated for embedding joint tape to create a strong, seamless connection between drywall panels. Taping is a crucial step in drywall installation to achieve a smooth and durable finish for walls and ceilings.

| Pros | Cons |

|---|---|

| Strong bond | Not good for finishing coat |

| Effectively conceals seams and joints | Longer drying time |

| Easy to sand smooth | Heavy |

| Low crack and separation risk | May shrink while drying |

Best for: Connecting drywall panels and fixing cracks

If you want a good finish on your wall, it's absolutely worth it to pay for professional taping and mudding. Many DIYers are tempted to pay someone to hang the drywall and do the rest themselves, but this is one area where a skilled contractor can make a huge difference.

Topping drywall mud represents the final stage in the journey to achieving a perfectly smooth and ready-to-paint drywall surface. This specialized type of drywall mud is designed to provide an ultra-smooth finish, hiding imperfections, and delivering a pristine surface for painting or other finishing touches.

| Pros | Cons |

|---|---|

| Creates a flawless, smooth surface | Not suitable for taping |

| Low shrinkage risk | Costly |

| Sands easily | Heavy |

| Can cover larger areas with less material | Requires some skill |

Best for: The final coat

In addition to choosing between the different types of drywall, you also have to choose between a dry or wet product.

Powdered dry compound, which must be mixed with water to achieve a suitable consistency, offers a longer shelf life and cost savings compared to pre-mixed wet mud. This makes the product a convenient choice for infrequent use.

With dry mud, you have the flexibility to adjust the mixing ratios to your preference and can customize the thickness. However, creating the right consistency requires skill and experience, and the mixing process can be time-consuming.

Pre-mixed or wet drywall mud can be used straight out of the container without requiring any mixing, and it guarantees consistent texture. This option proves to be a time-saver, particularly for smaller projects, and it is highly favored by beginners or individuals looking for convenient solutions.

However, wet mud has a shorter shelf life, and it may require disposal if left unused for a while. Additionally, wet mud is typically more expensive than dry powdered mud. While it provides a convenient option, it may not be as flexible in terms of adjusting consistency.

Choosing the right drywall mud for your project comes down to your needs and skill level—but you may need to use more than one type. Call a local drywall pro for advice, and consider these factors:

Versatility: If you want drywall mud that can be used on just about any project, choose an all-purpose compound. Just remember this type isn’t best for a smooth finish.

Timeliness: If you need rapid drying, consider quick-setting drywall mud for embedding tape or initial coats on corners and joints. Quick-setting compounds come in different drying time options, so select one that aligns with your project's speed requirements.

Adhesion: While you can technically use all-purpose or quick-setting compounds, taping compounds are specifically designed to ensure structural integrity. Only skip over this if you’re on a tight budget.

Smooth finish: If you want a perfect finish on your drywall, topping compound is the best way to achieve that. Not only does it deliver the finish you need during this drywall finishing level, but it does an excellent job of keeping imperfections away.

In addition to selecting from the types of drywall mud, you will also need to decide between dry or wet compounds:

Dry compound: Use if you’re experienced and prefer customization. It's cost-effective for larger projects and has a longer shelf life, making it suitable for intermittent use.

Wet compound: Use if you're looking for convenience, have a small task, or are a beginner. It saves time by eliminating the mixing step and offers a consistent texture. However, it’s pricier and has a shorter shelf life.

I had a great experience with Zenkai Restore. They came in quickly to address the water damage in my home, setting up fans and dehumidifiers to dry everything out. They also cut out the damaged drywall and thoroughly sanitized the framing. To top it off, they put up a solid airtight...

Canyon State Drywall has been one of the best home remodel companies I have worked with. They responded quickly and I had an estimate within 24 hours. The estimate was very competitive and they were able to start work in just a couple of days. They quoted a 3 day project time and there were...

I've delayed a few weeks in writing this review. I didn't have a great experience with this contractor and want to be honest and fair with my review. I hired this contractor to do some drywall repairs, which he was very accommodating to do, same day even. We spoke about what was to be...

Jesus n’ Sons Drywall are nice people who do great work. They were on time the price was right and they over delivered.

My overall experience was great. Jay came out to evaluate the best possible approach and came up with a great solution to minimize impact to the house/yard. On the day of the work, Miguel and Alex came out and did a fantastic job. They were on time, very professional and answered all the...

I did a project with them. It was in the summer. It was for landscaping.

The electrician was prompt, professional and friendly. Not only did he do a great job but he called a drywall team and arranged to them come to the house while he was there and fix the holes he cut to run wiring. That allowed me to get that done at the same time without having to make those...

Jeff O. arrived sooner than expected. Found the leak and the source of the leak. Detected the issues as being a previous carpenter defect. Jeff vacuumed the pools of water and repaired the cut pipe. He also recommended which steps should be next and suggested a company to come and dry the...

I hired XLT Construction to do drywall repairs, painting and carpet replacement in my home and I am very satisfied with the work they have accomplished. Owner Leonel LeBaron provided me with a very reasonable price with a quality product. I was very happy with the results of the work. I would...

I have had him do work for me several times over the years and his work is just excellent along with his attitude. Very reasonable and does the Best Drywall repair work of anyone I have ever met ... I live in a historic area of older homes, have older rentals, and I have learned to call him...

From average costs to expert advice, get all the answers you need to get your job done.

Skim coating drywall is a great alternative to replacement, and is often more affordable. Use this guide to estimate the cost to skim coat walls in your home.

Whether you’re trying to keep noise in or out, soundproofing materials are the way to go. Use this guide to see how much it costs to soundproof a room.

Drywall texture can create an attractive finish and add dimension to your home’s walls. This guide breaks down the factors that influence the cost to texture drywall.

Hanging and finishing drywall can be hard work if you don’t have experience. These professional-level drywall mudding tips make the project easier.

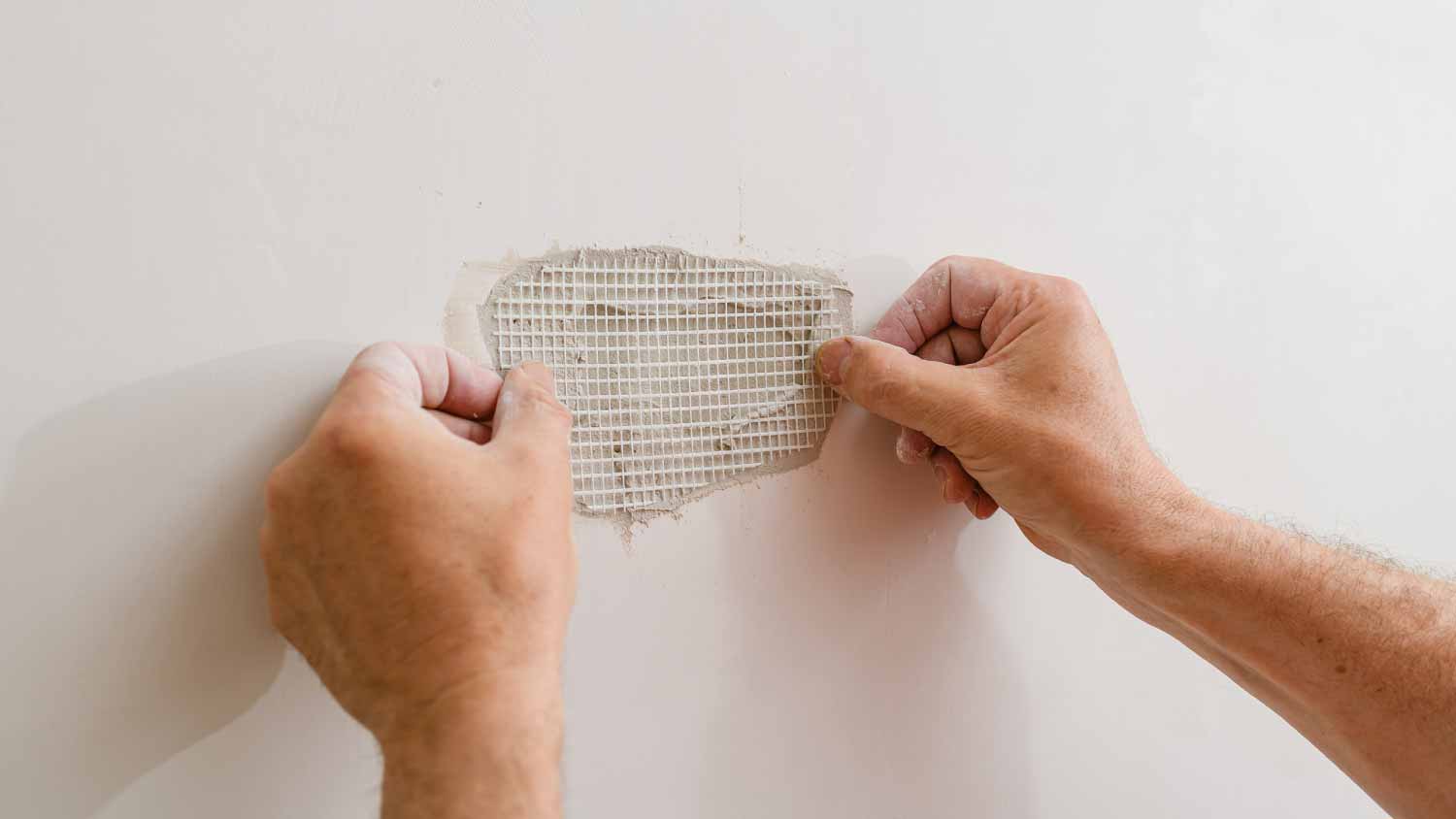

Mesh drywall patches add strength to small drywall repairs. Learn why mesh patches are important and when to use this material for drywall repairs.

Skim coating helps smooth out drywall before you apply paint. Learn how to skim coat a wall in eight steps with this guide.