Which Pipes Are for Gas Lines? The 6 Best Types to Consider

Keep in mind durability, safety, and longevity

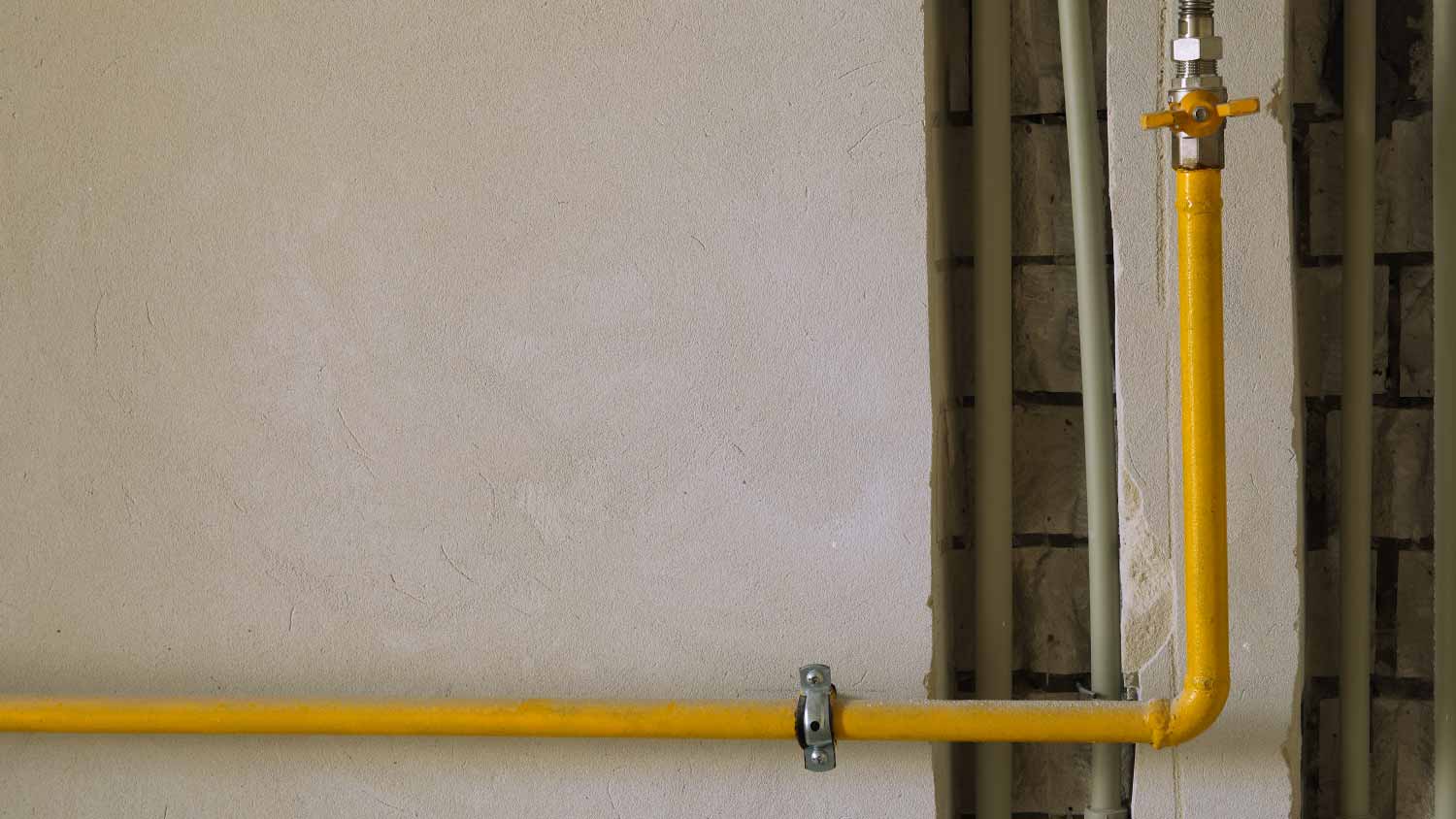

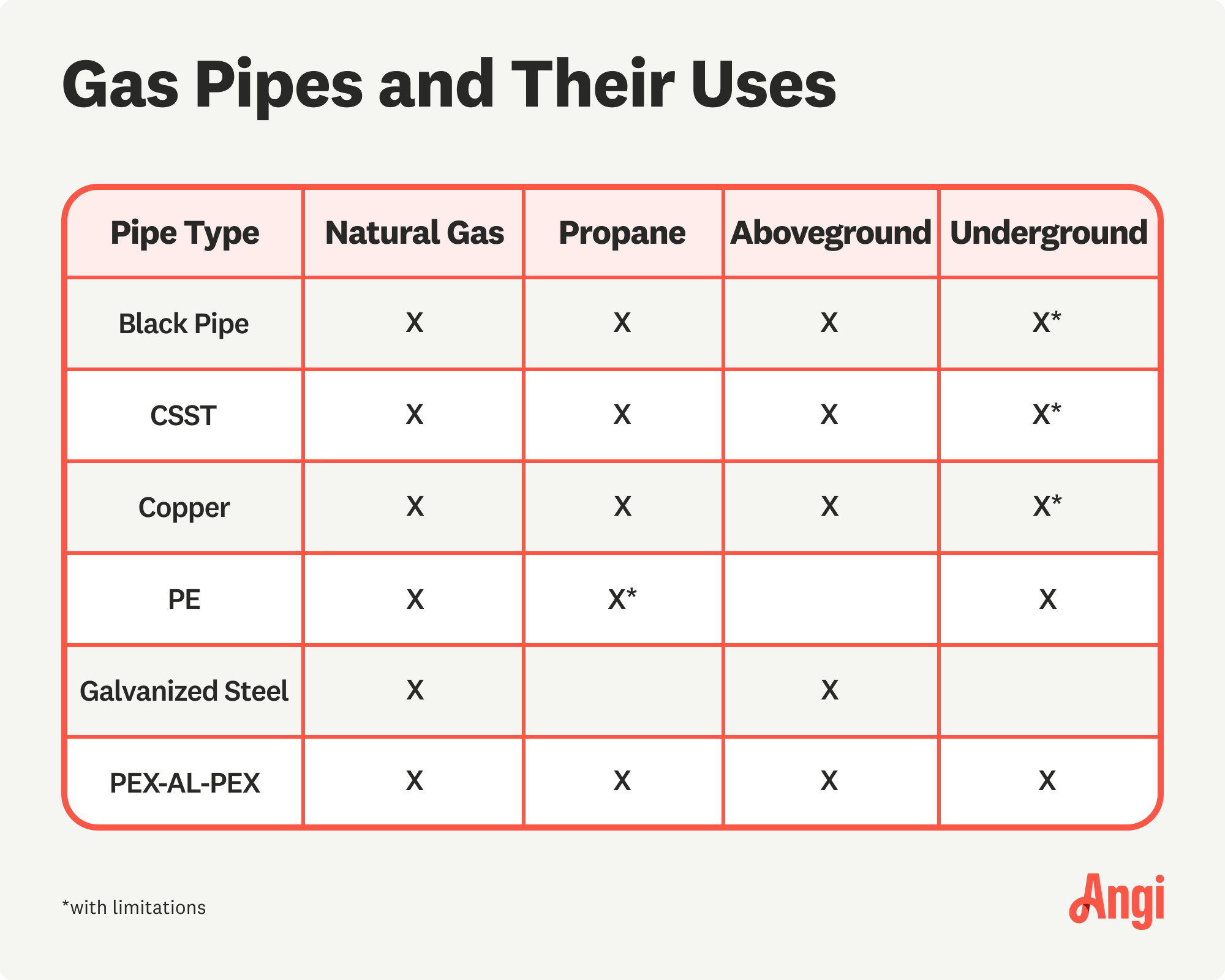

Choosing the best pipes for home gas lines means enjoying toasty heat in the winter and cooking hearty meals on the stove without the worries of dangerous leaks and pipe failure. Six of the most common types of gas line pipes are black pipe, corrugated stainless steel tubing, copper, polyethylene, galvanized steel, and aluminum-plastic composite.

Whether you’re building a new home or looking to repipe your current residence, you’ll see that some pipe types will work better for you than others. Your gas installer can help you figure this out now so that you’re ready when construction begins.

1. Black Pipe

Black pipe is commonly used for gas lines because it’s highly durable and reliable. It’s a steel pipe with a black exterior. The black color is from the natural oxidation of the steel when exposed to air. The layer of iron oxide and ferric oxide prevents rust and corrosion. However, the black layer can become damaged in humid weather or high-moisture conditions. It costs $4.90 per linear foot and has a lifespan of 40 to 70 years.

| Pros | Cons |

|---|---|

| Highly durable | Airtight seal can degrade over time |

| Straightforward installation | Susceptible to high-moisture conditions |

| Resistant to rust and corrosion | Requires regular maintenance |

Best for: Traditional homes

2. Corrugated Stainless Steel Tubing (CSST)

Corrugated stainless steel tubing (CSST) is a flexible pipe that makes installation a lot easier, especially when you want to run gas lines under floor joists, above ceiling joists, and inside walls. It doesn’t require soldering and there are few joints. Another advantage to these is that they’re less likely to be damaged by earthquakes. On the downside, CSST requires proper bonding and grounding to avoid problems from lightning strikes on the property or nearby, like electrical shocks, gas leaks, and fire. It costs $2 to $4 per linear foot and lasts 30 to 50 years.

| Pros | Cons |

|---|---|

| Easy to install in hard-to-reach areas | Underground installation can lead to pinhole leaks from corrosive soil |

| Durable and resistant to corrosion | Specialized training is required for installation |

| Less likely to be damaged by earthquakes | Impact or crushing can damage these pipes |

Best for: Homes with nontraditional layouts

3. Copper

Copper pipes are on the lower end of the price range at $1 to $3 per linear foot and are the most cost-effective solution for gas with a lifespan of 50 years. You can opt for flexible copper tubing that’s easy to install in tight spaces and wherever you need it. It’s durable and has been used for gas lines for over 30 years.

The downside of copper is that it’s not allowed in all areas because the material can wear down over time and sustain damage through corrosion or pinhole leaks. If you’re not sure if it’s allowed in your home, you can call a natural gas plumber near you to find out.

| Pros | Cons |

|---|---|

| Durable | Not allowed by some building codes |

| Easy to install | Can corrode |

| Affordable | Can develop pinhole leaks |

Best for: Budget-conscious homeowners

A professional should always do gas hookups because of the serious dangers and risks involved. Signs you might need gas plumbing repairs are rust, damaged connections, or a gas smell. If you smell gas, turn off your appliance immediately and call a professional to inspect it.

4. Polyethylene (PE)

Polyethylene pipes are durable and can withstand extreme weather and high levels of moisture without cracking, corrosion, or rust. You can also use high-density polyethylene (HDPE), which is a more durable version of PE pipes.

Installation is easier with PE pipes than with steel pipes because PE is lighter and more flexible. However, installers must watch out for sharp objects like nearby rocks that can cause damage. You can only use PE pipes underground, not in your home aboveground. These pipes can last 100 years and cost $1 to $2 per linear foot.

| Pros | Cons |

|---|---|

| Durable against moisture and weather | Only allowed for underground use |

| Long lifespan | Not as strong as steel |

| Doesn’t require constant maintenance | Rocks and sharp objects can puncture the pipe |

Best for: Underground installations

5. Galvanized Steel

Galvanized steel pipes for gas have a zinc coating on the exterior and interior that protects them from corrosion and rust. While the zinc coating is intact, these pipes are extremely durable, corrosion-resistant, and energy-efficient.

One downside is that the zinc can wear down over time, leading to serious damage like leaks. For this reason, galvanized steel is not allowed by some building codes, and it’s only usable for aboveground installations. This option costs $2 to $9 per linear foot and lasts 20 to 50 years.

| Pros | Cons |

|---|---|

| Durable | More costly compared to other types |

| Energy-efficient | Not allowed by some building codes |

| Corrosion-resistant while the zinc coating is intact | Regular inspections are vital since the pipes can get damaged over time |

Best for: Aboveground installations

6. Aluminum-Plastic Composite (PEX-AL-PEX)

Aluminum-plastic composite pipes, also referred to as PEX-AL-PEX, have polyethylene on the interior and exterior with an aluminum tube in the middle. These pipes are durable, require limited joints like copper, and are energy-efficient compared to black pipes.

PEX-AL-PEX is susceptible to damage from UV rays, requires specialized knowledge to install, and isn’t allowed in all areas. Some people find them visually unappealing because they don’t install perfectly straight, and you’ll notice some curvature even when it’s vertical. The lifespan is 50 years, which is comparable to other pipe types.

| Pros | Cons |

|---|---|

| Durable and lightweight | Visually unappealing |

| Energy-efficient | Susceptible to UV damage |

| Doesn’t corrode | Regular inspections are required |

Best for: Alternative to common pipe types