Whether you’re trying to keep noise in or out, soundproofing materials are the way to go. Use this guide to see how much it costs to soundproof a room.

Here’s how a board made of paper and pressed powder can be strong enough to hold up your house

Drywall is made of processed gypsum sandwiched between two sheets of paper.

Some drywall uses other materials, such as fiberglass, mica, or wax, to add properties such as water resistance.

Gypsum is a mineral that has been used in home construction for thousands of years.

If you think your home has drywall that was imported from China between 2001 and 2009, call a pro to discuss replacing it.

You used to need to slather wet plaster over your walls in multiple, slow-drying layers to build your home. Today, all you need to do is hang a few sheets of drywall. But what is drywall made of? These boards contain gypsum, just like plaster, but it’s already dried, hardened, and ready to hang. Learn more about the different components of drywall below.

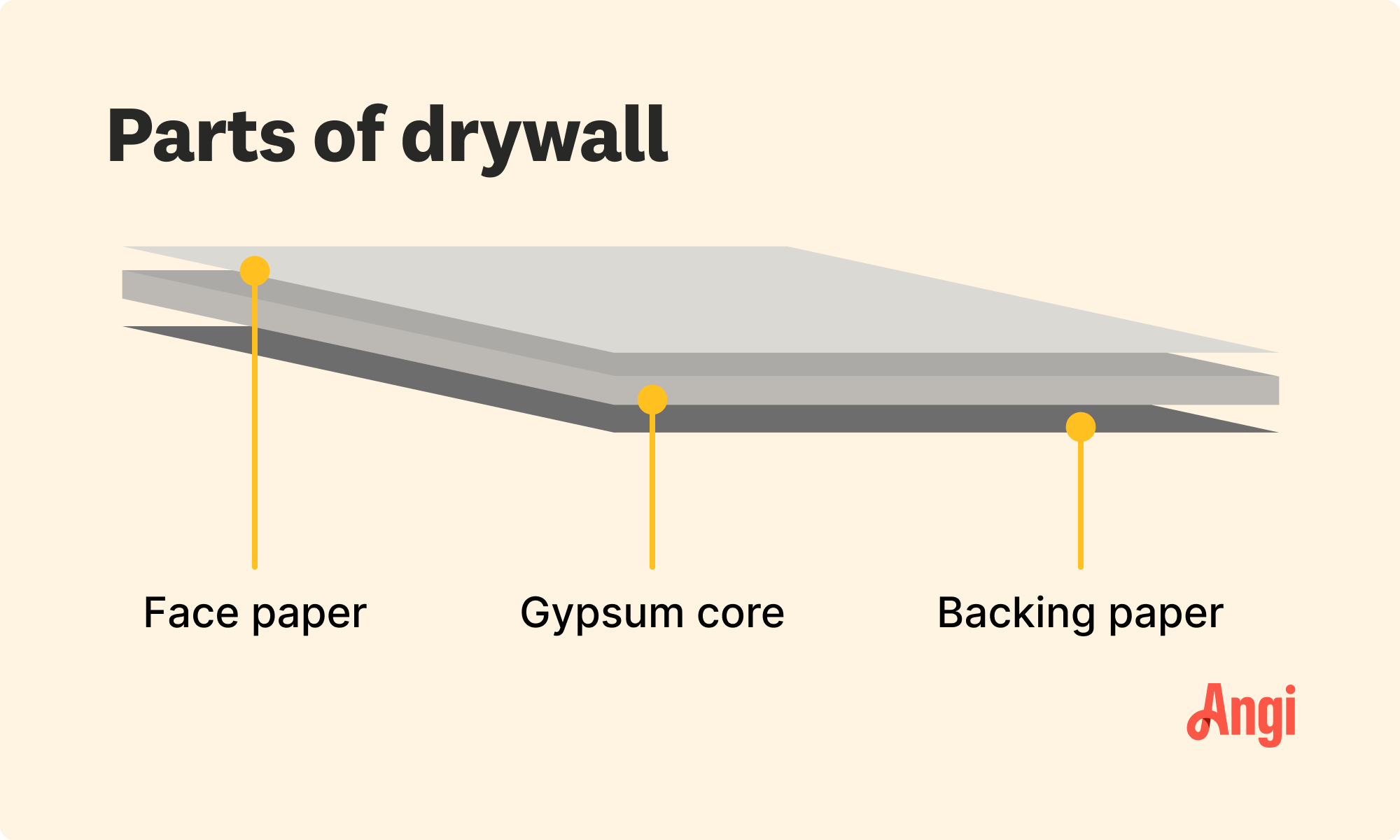

A sheet of drywall is made of three layers: paper, a gypsum blend, and another layer of paper. Some drywall also contains other ingredients and additives, depending on the type.

The main ingredient in drywall—about 90% of it—is gypsum: a soft, naturally occurring mineral that is also used in plaster, fertilizers, and sidewalk chalk. It’s also why you’ll hear drywall sometimes referred to as “gypsum wallboard” or “gypsum board.” Part of the reason gypsum is used in making drywall is because it’s naturally fire-resistant.

To make a drywall board, manufacturers crush, heat, and partially dehydrate gypsum. The resulting powder is re-mixed with water and additives to form a paste, which is then spread between paper and dried to form a board with rock-like hardness. Finished drywall can hold as much as 10 pounds of weight without anchors or reinforcement. A sheet of drywall itself weighs between 50 and 70 pounds, with most of the weight coming from the gypsum.

On each side of the gypsum layer is a cellulose paper backing. This paper makes drywall boards easier to handle, store, and transport. The paper facing on drywall also allows for a smooth finish on your wall after mudding with joint compound and painting.

However, the paper is susceptible to mold damage, especially when used in wet rooms such as kitchens and baths. That’s why pros often use moisture-resistant drywall or add plastic behind drywall in moisture-prone rooms.

Drywall may also contain additives that lend the drywall different properties, such as soundproofing or moisture resistance, depending on their use.

| Drywall Material | Added Properties |

|---|---|

| Mica | Workability, crack resistance |

| Fiberglass | Strength, fire resistance |

| Resin | Moisture resistance |

| Wax | Moisture resistance |

| Plasticizers | Workability |

| Perlite | Soundproofing |

| Vermiculite | Soundproofing, fire resistance |

| Boric acid | Strength, fire resistance |

| Wood fibers | Flexibility, soundproofing |

| Fly ash | Strength, moisture resistance |

Using different materials allows drywall manufacturers to create different types of drywall that are suitable for different needs. For example:

Greenboard: When manufacturers seal the paper on a drywall board with a waxy coating, they increase its water resistance. The result is a type of drywall called greenboard because the paper is often green in color.

Type X: Some types of drywall, such as Type X and Type C, have fiberglass added to the gypsum core. This is designed to provide extra fire resistance, making it a good choice for ceilings, garages, homes with fireplaces, or anywhere you need to reduce the risk of fire spread.

Paperless: Using fiberglass on either side of the gypsum core instead of a paper backing can inhibit the growth of mold. This “paperless drywall” is especially useful for rooms with higher moisture levels. However, you still wouldn’t want to drywall over tile or use it in shower stalls.

Cutting and sanding drywall creates a fine, silica-containing dust that can irritate your eyes, nose, throat, and lungs. Similarly, wet drywall can harbor mold spores that can cause allergic reactions, including difficulty breathing. And the fiberglass in some types of drywall can irritate your skin, eyes, and lungs.

That’s why it’s important to wear plenty of personal protective equipment (including a respirator mask and goggles) and properly ventilate the area when working with drywall. The easiest way to stay safe while working with drywall is to leave these jobs to a local drywall pro who already has all the safety equipment.

Crystalline silica is a toxic dust that's often generated during drywall installation, which can cause respiratory issues if exposed over time. A professional drywall installation company has the right tools to protect your home and ensure safe air quality after your project is completed.

Some homeowners have reported health problems and corrosion that may be related to drywall imported from China between 2001 and 2009. The components of this drywall may release corrosive sulfuric gases, which can be a safety hazard. If you believe you have “problem drywall,” the U.S. Department of Housing and Urban Development recommends hiring a professional to replace it.

If you want to install, repair, or replace drywall safely, hire a drywall installer. They’ll have the appropriate know-how and equipment to do the job properly.

From average costs to expert advice, get all the answers you need to get your job done.

Whether you’re trying to keep noise in or out, soundproofing materials are the way to go. Use this guide to see how much it costs to soundproof a room.

Pre-drywall inspection costs vary depending on the home size, build complexity, and reporting you receive. Estimate your budget with this cost guide.

Skim coating drywall is a great alternative to replacement, and is often more affordable. Use this guide to estimate the cost to skim coat walls in your home.

Installing drywall can be a messy renovation project. Learn how to get rid of drywall dust like a pro with these handy tips.

When choosing between types of drywall mud, you need to consider your project and how quickly you can work. Use this guide to help you select the best drywall mud for your project.

When hanging objects, you will use different types of drywall anchors. Use this guide to determine which anchor to use and when.