Get a clear estimate for solar water heater repair cost. Learn what impacts pricing and how to budget for your solar water heater repair.

Behind the scenes of going solar

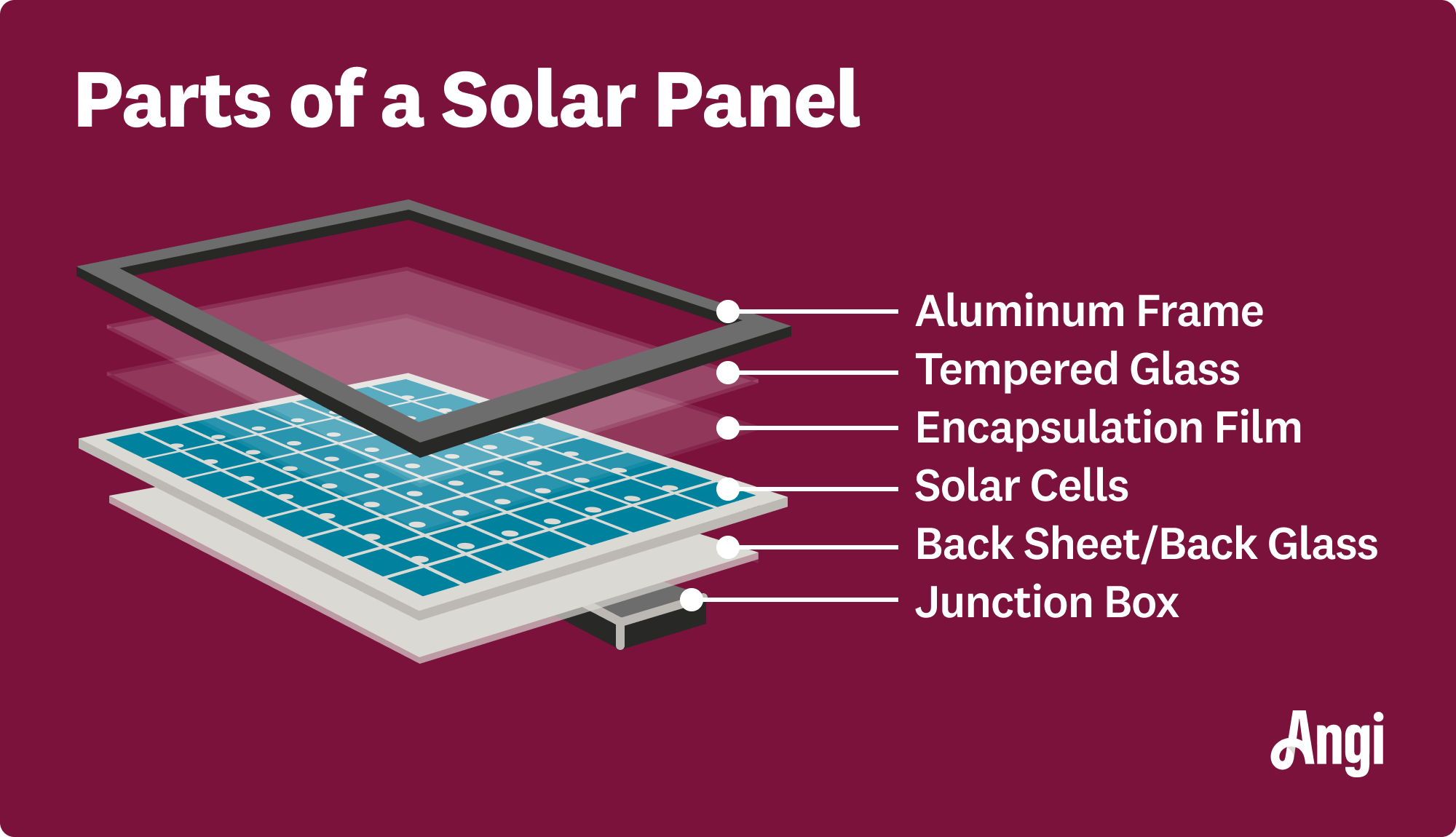

The solar cells are the most important part of a solar panel because they generate power.

The frame, glass sheets, and encapsulation film help protect the solar panel.

The wiring, junction box, and inverter transmit and convert sunlight into usable electricity.

They’re sleek and help you save money on electric bills, but have you ever wondered what solar panels are made of? Understanding these details will help you make an informed decision about which panels you want to install. Discover all the components that make up a solar panel, including a small dive into the various types of solar panels on the market.

Looking at a solar panel in passing, you might not realize how many different parts make up a unit. Here are seven solar panel parts you should know about.

Solar cells, also called photovoltaic panels or PV for short, are the part of the solar panel that turns sunlight into electricity. According to the U.S. Department of Energy, the most common types of solar cells are monocrystalline and polycrystalline silicon, representing over 84% of solar panels.

The main difference between monocrystalline and polycrystalline solar panels is their construction.

| Monocrystalline Solar Panel | Polycrystalline Solar Panel |

|---|---|

| Made up of multiple silicon wafers | Made from silicon fragments that are melted together |

| Black | Blue |

| Higher costs | Lower costs |

| Last longer | Shorter life span |

| Higher efficiency | Less efficient |

Thin-film solar cells are made of photovoltaic materials, including cadmium telluride, copper indium gallium selenide, or amorphous silicon. These flexible panels are made from thin layers of material and don’t require an aluminum frame, so installation is simpler. The downside is that they’re larger and less efficient than crystalline silicon panels.

The aluminum frame holds all the solar panel pieces together. It increases the solar panel's rigidity, prevents moisture and debris from entering, and has mounting holes or clamps for quick installation.

Solar panels have a piece of tempered or semi-tempered glass on the front and one on the back of the panel. The piece on the back is called the back sheet or the back glass.

The glass protects the solar cells from potential damage. Since solar panels are mounted onto roofs, they must withstand harsh weather like extreme heat, cold, and wind damage. The pieces of glass are thin, ranging between 1.6 and 7 millimeters thick. Even so, the heavy glass makes up 75% to 97% of the solar panel's weight.

“While solar panels are equipped with shatter-resistant tempered glass, they can sustain damage from hail or debris carried by strong winds. Monitor your rooftop array after extreme weather conditions, review your warranty, and call your installation company if any damage occurs.”

— Mike Naughton, CEO and Founder of Integrity Energy, Cleveland, OH

The solar encapsulation film is applied to the top and bottom of the solar cells and adheres to the tempered glass and back sheet. It prevents the cells from moving or breaking, filters UV rays, and prevents corrosion.

Busbar wiring, made of aluminum or copper, sits between the solar cells and transmits the direct current (DC) electricity from solar panels and into the inverter. DC electricity isn’t usable in your home until it’s converted into alternating current (AC) electricity by the inverter. DC electricity flows in the same direction, while AC electricity flows in different directions.

The solar panel junction box is on the back of the panel. All the connector wires running through the panel go into the junction box.

The solar inverter turns the DC generated by solar panels and converts it into AC electricity, which is what all of your home appliances and electronics use. This electricity is more cost-effective and safer than DC power, so it’s the standard for modern homes.

The solar cells are made from silicon, which is either extracted from silica sand or manufactured in a lab. It’s more common to use lab-made silicon than natural silicon. The material is heated to over 3,600 degrees Fahrenheit, cooled, and then liquified.

Small amounts of boron and phosphorus are added, turning the silicon into a semiconductor. The silicon is sliced into thin sheets called wafers, and antireflective coatings are applied to the wafers so they absorb sunlight. Sixty to over 70 wafers are soldered together to make up a panel. The process differs depending on the type of solar panel. The panel is mounted on a metal frame with a backing and a glass front.

When sunlight hits the solar cells, it produces electrons. These electrons make an electric charge, which is transferred through the wiring and into an inverter. The electricity enters the inverter as DC current and is turned into AC current, so it’s compatible with everyday appliances and electronics.

The details behind how solar panels work can get complex, but if you reach out to a local solar panel installer, they can help you answer all your questions.

From average costs to expert advice, get all the answers you need to get your job done.

Get a clear estimate for solar water heater repair cost. Learn what impacts pricing and how to budget for your solar water heater repair.

Discover the Tesla Powerwall installation cost, including average prices, cost factors, and tips to help homeowners budget and save on their Powerwall project.

Discover the average solar panel installation cost, key price factors, and expert tips to help you budget for your solar project.

Is your home a good fit for solar panels? It all depends on your roof, sunlight exposure, and energy bills. Use this guide to find out.

If you’re making the switch to solar energy, you’ll want to know the difference between solar panels versus solar shingles. Here are the pros and cons of each.

Looking to install solar panels? While they pair well with most roofing, choosing the best roof for solar panels can ramp up energy efficiency.