What Is a Trenchless Sewer Repair?

Get your sewer line replaced with minimal excavation

Pipe-bursting and pipe-coating are the two possible methods.

Trenchless repair minimizes excavation in your yard, as well as the repair cost.

Trenchless sewer repairs are expected to last for up to 100 years.

Trenchless sewer repair is a relatively new repair method for buried sewer lines that allows you to replace or reinforce your existing underground sewer lines while minimizing digging and labor costs. Trenchless sewer line replacement costs significantly less than traditional replacement, as a result, making it an attractive option where it’s possible.

In this guide, we’ll explain what the process entails, how trenchless sewer repair works, and why it might be the best option for your home.

What Is Trenchless Sewer Replacement and Repair?

Trenchless sewer replacement aims to replace buried sewer pipes without the extra labor and potential damage that comes with traditional, trench-digging replacement.

There are two primary methods of trenchless sewer replacement: pipe bursting and pipe lining. It’s possible to use these methods whether you’re connected to a public sewer system or if you have a septic system in place. In most cases, both begin with a sewer line camera inspection to identify the portion of the pipe that needs repair or replacement.

Pipe Bursting Method

With the pipe-bursting method, your sewer repair technician will dig two small access points down to your sewer line and then cut portions of the line out. They will then feed a steel cable through the middle section that needs repair.

The tech will attach a piece of metal wider than the sewer line to one end of the cable, followed by a length of new high-density polyethylene (HDPE) pipe. From the other access point, the tech will use machinery to pull the cable through the length of pipe. The metal widener cracks the existing pipe, and the HDPE pipe will fall into place behind it as the cable feeds through to the second access point.

Finally, the tech will connect the two ends of the new pipe to the remaining portions of your sewer line. The cracked pieces of the replaced section remain underground.

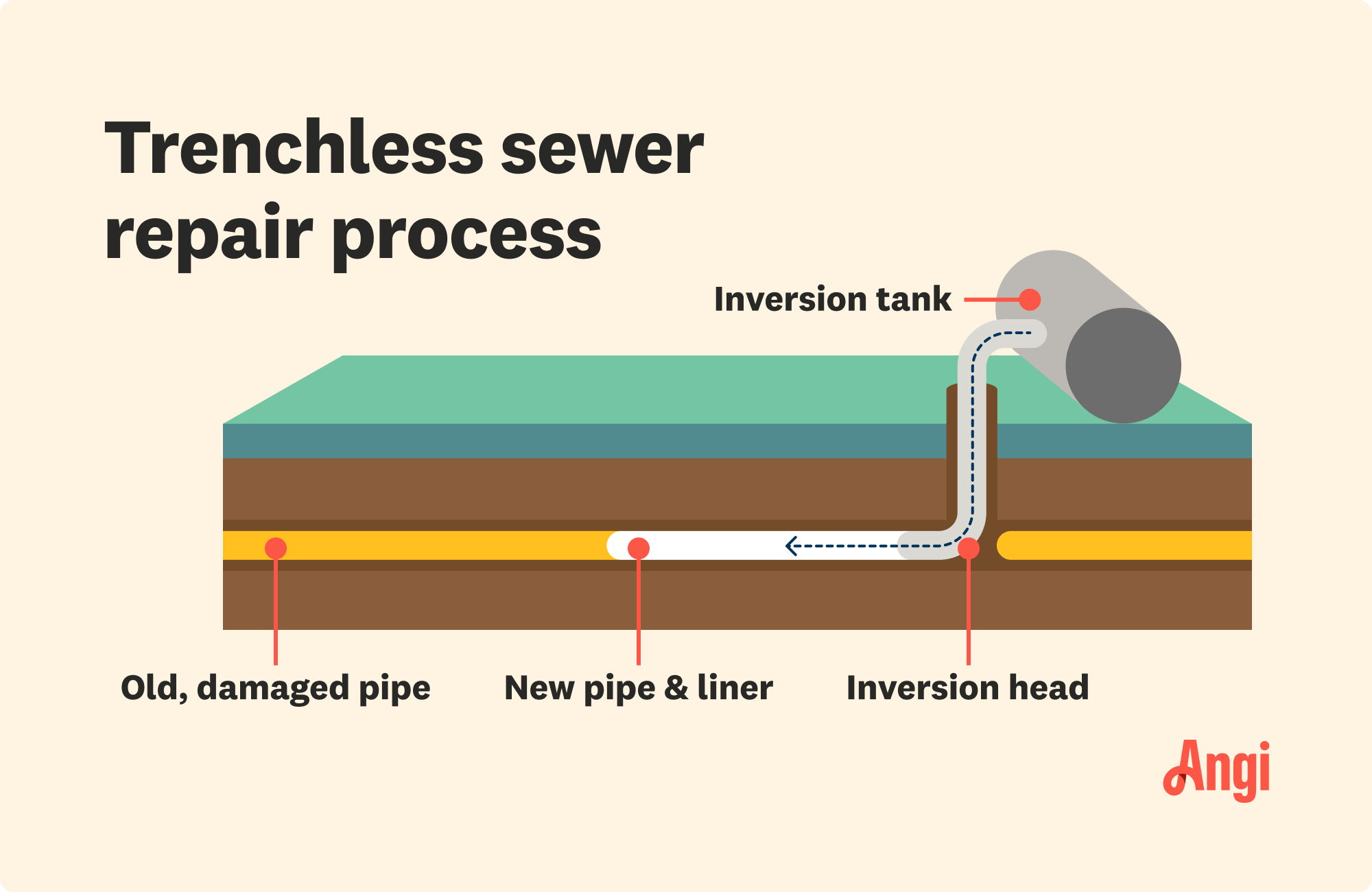

Pipe Lining Method

Pipe lining is a method best reserved for underground pipe that needs repair rather than replacement. After a camera inspection to locate the leak or damaged portion of the sewer line, your tech will dig two small access points and cut into the sewer line at both dig sites.

The tech will then feed a cable through the pipe and use the cable to feed a pipe liner through as well. Once it’s situated properly, the tech will inflate the lining and treat it with heat or UV light to cure it in place. When the tech removes the cable, the liner remains on the inside of the line and will serve as a new inner pipe for decades to come.

Finally, your tech will reconnect the repaired section.

Trenchless Sewer Repair and Replacement Pros

When you compare the labor and installation processes involved in traditional sewer line replacement versus trenchless options, it’s clear that there’s a lot going for trenchless.

Reduced Property Damage

Because a plumbing crew doesn’t need to dig a trench following the path of your sewer line, everything in its way—including landscaping, hardscaping, and even buildings—is safe from damage or demolition. There may be minimal damage around the access holes, but many crews try to minimize this by containing dirt on tarps to prevent making a mess and preserving dug-up grass or shrubbery to replant later.

With the minimal excavation, you’ll still retain most of your lawn or garden, and you will rarely need to repair decks, patios, or walkways, saving you time and money after the repair is completed.

Potentially Lower Costs

Depending on the complexity of your project, the average trenchless sewer line replacement cost can be significantly less than the traditional method. This is mostly due to the fact that the labor is much less involved. Your sewer repair tech won’t need to bring in digging machinery or spend time backfilling around the repaired line.

In some cases, the cost for this service could be as much or even more as the traditional method. But you should take into account that you’ll still save on the time and effort of restoring your property because there won’t be as much damage.

Faster Job Completion

Traditional sewer line replacement can easily take over a week or more, with crews spending hours digging to expose the entire sewer line. Beyond the trench work, this process can disrupt your life—crews might need to close your street for safety or equipment access, and you’ll lose sewer services in the meantime. No flushing toilets, no washing dishes, no brushing teeth—nothing involving wastewater. It’s a tough way to live for days on end.

That’s why many homeowners opt for a trenchless method. With just two small access holes, crews can install or repair pipes in as little as a day, minimizing disruption and getting you back into operation fast.

Long-Lasting Results

The materials your repair technician will use in a trenchless sewer repair are expected to last for between 50 and 100 years, which is just as long as a traditional repair should persist. Not only will you save money on the initial work, but you should also see increased savings over time due to the repair’s longevity.

Trenchless Sewer Line Repair and Replacement Cons

If you’re in need of a new sewer line, trenchless technology may seem like a clear winner. However, there may be times when it’s not a good fit.

Requires Trained Technicians

First and foremost, you should only hire a trained local sewer service to tackle trenchless pipe lining or replacement. This isn’t a job that any plumber can take on. Plus, this is a relatively new technology, so you may struggle to find a company in your area that offers the service and is experienced enough with it to trust.

Qualified technicians undergo training and certification so that they can evaluate whether trenchless technology is suitable for a project and then properly execute the job. Even if a company advertises trenchless replacement, it may not have plumbers with the skills to do the job correctly, which could create even bigger problems down the line.

Not Suitable for All Circumstances

As amazing as trenchless sewer replacement sounds, it’s not always an appropriate choice. If you’re dealing with a collapsed pipe, an incorrectly installed pipe, or a pipe that’s burst and caused damage to surrounding utilities, you may not be able to take advantage of the convenience of trenchless technology.

In these cases, you’ll need to settle for traditional trenching to remove the old pipe, address the additional issues, and install the new sewer line.

Your repair technician should be able to tell you if trenchless repair is a good fit for your home.

Frequently Asked Questions

Most experienced professionals can get an entire trenchless pipe lining project done in a single day, and smaller projects might take as little as three to four hours. If your technician uses machinery to dig the two access points, the job will likely be faster, whereas manual digging will take a bit longer and could push the project above six hours.

A trenchless sewer line can last between 50 and 100 years, depending on the materials used and climate conditions. Most modern trenchless methods, like pipe lining or pipe bursting, use high-density polyethylene (HDPE), a durable material resistant to corrosion, tree roots, and shifting soil. Professional installation and regular maintenance can maximize the sewer line's lifespan.

High-density polyethylene (HDPE) is the most common material for trenchless sewer repair. It’s flexible and easy to maneuver underground without excavation, and it’s durable enough to last for between 50 and 100 years if your tech installs it properly. HDPE also resists corrosion, and it’s more affordable than steel or iron alternatives. As such, it ends up being a cost-effective option both when it comes to the material itself and the labor required to install it.

- What Are Your Options for Sewer Line Repair?

- Replacing a Sewer Line From Your House to the Main Line? Here Are 8 Things to Consider

- What Is a No-Dig Trenchless Sewer Repair and Is It Worth It?

- Sewer Line Replacement or Repair Costs

- Tips for a Successful Sewer Line Installation, Replacement, or Repair

- 8 Warning Signs of a Clogged Sewer Line

- Why Is My Sewer Bill So High? Possible Causes and Solutions

- Is Sewer Gas Dangerous? Everything You Need to Know

- 5 Ways to Avoid a Sewer or Drain-Cleaning Scam

- How to Keep Your Sewer Sanitary Line Clean and Clear