Get the latest snow removal cost estimates, including average prices, key cost factors, and tips to help homeowners budget for safe, efficient snow removal.

You won’t even need your snow shoes this winter

A snow blower is a worthy investment if you live in a cold winter climate. But if your blower breaks down and needs repair, it can throw off your entire schedule—and budget. Snow blower repairs can be costly, depending on the issue at hand and the age of your machine. Avoid these challenges altogether by following our top tips for snow blower maintenance to keep your machine running smoothly all winter long.

If the belt is malfunctioning, your snow blower won’t be able to move forward. If you’re not experienced with basic mechanics, it can be safest and easiest to hire a snow removal company to help repair your snow blower.

Similar to how you’d change the oil in your car and lawn mower to keep it running smoothly, your snow blower needs it too. Check your snow blower’s owner’s manual to see how often you need to change the oil in your individual machine. If you know how to change the oil yourself, you can buy the oil at your local hardware store or online. If not, a pro can do this for you when you schedule a tune-up.

Ensure the tires are at the right pressure and the chains are lubricated and aligned at the beginning of the winter season.

Skid shoes set the minimum depth the snow blower will scoop up snow. If you adjust the skid shoes, the machine won’t scrape the ground, and you won’t throw rocks if you’re plowing a rough surface, such as a gravel driveway.

The auger is the part that pulls in snow so that the snow blower can shoot it off the driveway or sidewalk you’re plowing. This means the auger is essential for a snow blower to function. A professional snow blower repair expert can check and replace the auger, if needed. They can also review the other necessary parts on this list.

The spark plug helps get your snow blower’s engine running. Most snow blowers don’t actually have an air filter, but if yours does, this is also something to check.

This goes without saying: Before you can use your snow blower, it needs to have sufficient fuel. It’s helpful to always keep a safe gas canister filled in your garage after each use so you can refuel as needed without having to make a trip to the gas station in a snowstorm. This way, you can use your snow blower right away in the moments when you need it most.

If you’re storing gasoline in your garage for several months, there are fuel stabilizer products you can purchase to mix in with the gas to keep it fresh and usable.

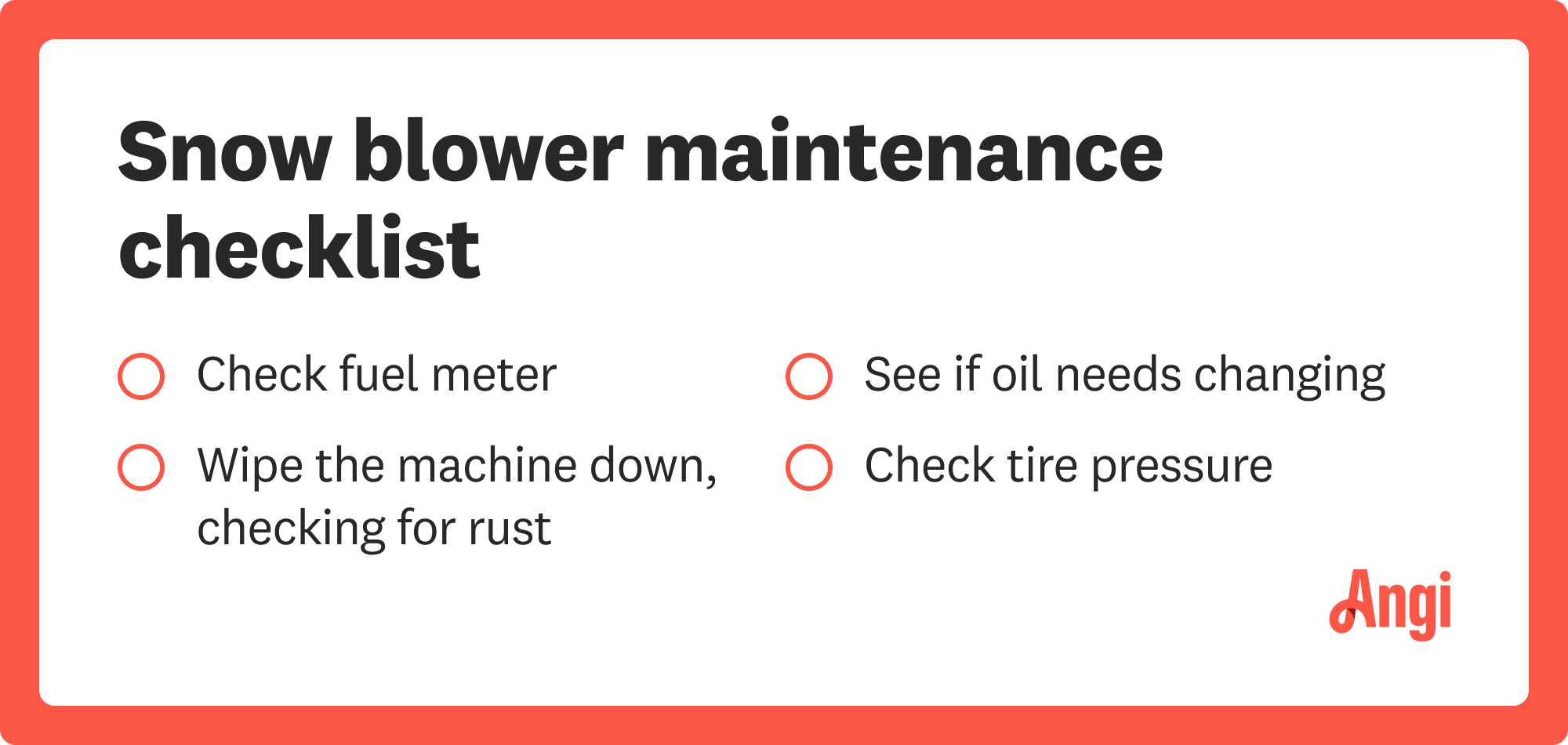

Your snow blower should be serviced annually to keep it in good condition long-term. You can schedule maintenance work with your local snow removal pros for professional service or DIY by following a simple snow blower maintenance checklist. Keep in mind a large part of taking care of your snow blower involves keeping up a steady oil and gas supply. Change the oil at the start of each winter season, and regularly monitor the gas meter as you use your machine.

Leah Lopez Cardenas contributed to this article.

From average costs to expert advice, get all the answers you need to get your job done.

Get the latest snow removal cost estimates, including average prices, key cost factors, and tips to help homeowners budget for safe, efficient snow removal.

Discover the cost to install snow guards. Learn about average prices, key cost factors, and tips to save on your snow guard installation project.

Using traditional rock salt to melt ice can negatively impact the environment, your pets, and more. Learn how to melt ice with salt.

Are you in the market for a new snow blower but have no idea what size is best? Learn how to pick what size snow blower you need.

Nothing ruins a good deck like ample and consistent build-up of snow and ice. Whether your outdoor deck features wood, composite material, or even PVC, here are steps to take to keep it safe and damage-free during those nasty winter months.

Deciding between a gas snow blower vs electric? Weigh all of the pros and cons with this informative guide before you buy.