Getting a wind mitigation inspection can work in your financial favor. Learn about the average wind mitigation inspection cost, including ways to save.

Explore the possibilities of single-ply roofing

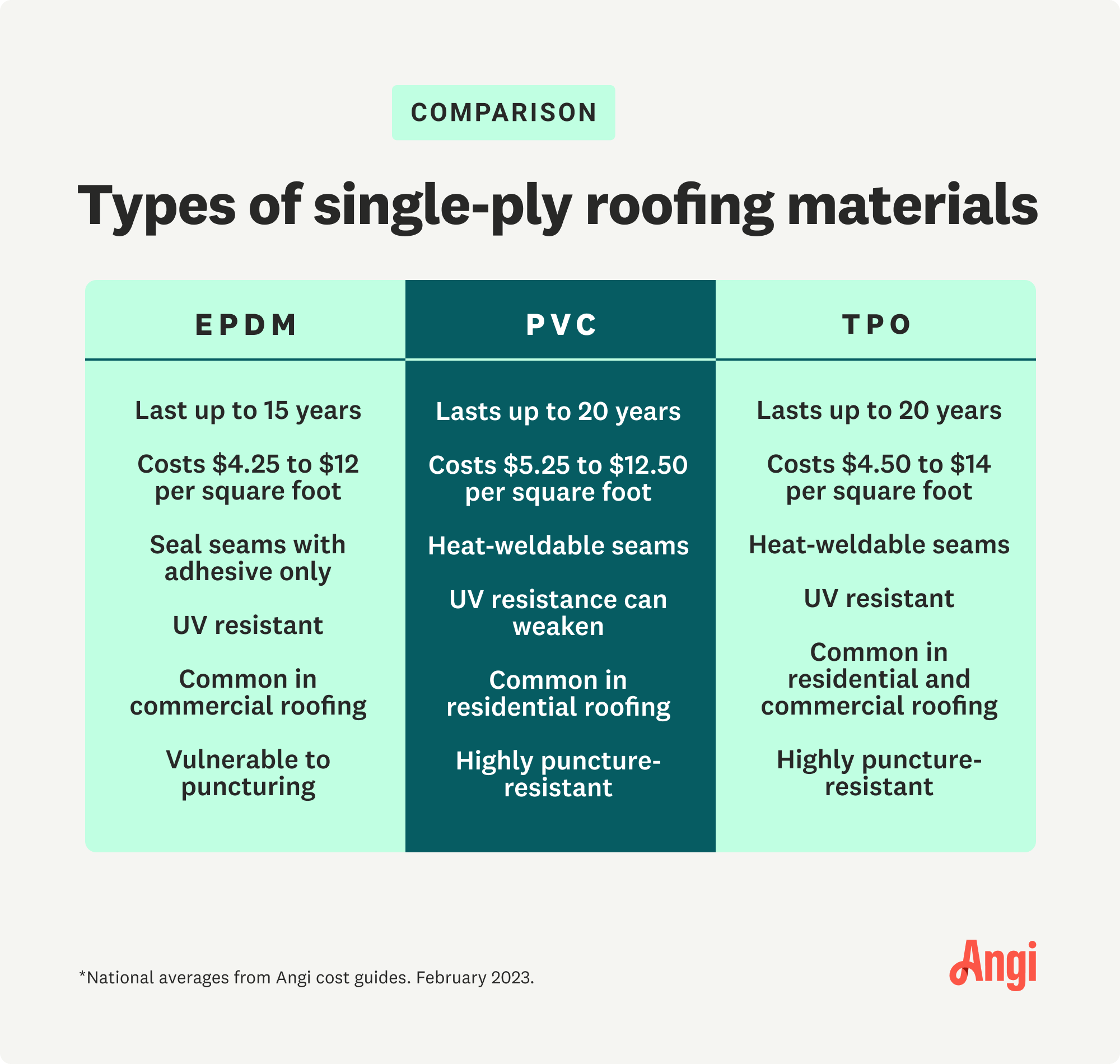

There are three common types of single-ply roofing: EPDM, PVC, and TPO.

Single-ply roofs typically cost $7,500 to cover 1,000 square feet.

Single-ply roofing lasts for between seven and 30 years, depending on the quality and type.

Low-sloped roofs provide a clean, modern look for your building, but they can pose a challenge when it comes to keeping precipitation outside where it belongs. There was a time when there were only a couple of labor-intensive ways to keep water and snow from penetrating a low-sloped roof. Single-ply roofing or rubber roofing has changed all that and now offers several solutions for buildings with a minimal roof pitch. Read on to learn everything you need to know about single-ply membrane roofs, including the different types and their costs.

Single-ply roofing is a suitable option for flat roofs made from a single layer of waterproof material. The roofer you hire will most often attach the material with adhesive, but using mechanical fasteners is sometimes an option, as well. Your professional will then seal any seams in the material and, depending on the type of roofing, apply a protective coating to reduce the risk of UV damage.

Single-ply rubber roof materials like TPO and PVC come in two primary forms that have varying qualities. Thermoplastics are flexible sheets of membrane that your roofer can heat numerous times to shape, stretch, and mold them into shape. Thermoset plastic single-ply roofing systems are also known as EPDM, which are rubber roofs made from ethylene, propylene, and diene monomers.

Single-ply roofing membranes are becoming increasingly popular due to their affordability and the minimal maintenance they require. The materials are more expensive than those for a built-up roof (BUR) or modified bitumen roof, but the labor is less intensive, leading to good overall affordability.

The potential savings come in the long run, though, as they require less maintenance than many other flat roof options and have a lower risk of developing leaks in many cases. Single-ply roofing can last for 20 to 30 years, depending on the climate in your area, making them a good investment over time. Some options, like TPO roofing, are white and reflect sunlight well, which can help reduce cooling costs in hotter climates, too.

"Single-ply membranes like EPDM, TPO, and PVC excel on low-slope or flat roofs, particularly in commercial and multi-family settings, where energy efficiency and waterproofing are priorities. However, they are not ideal for steep-sloped residential roofs, where materials like tile or asphalt shingles offer better durability and curb appeal."

— Paul Watrous, President of the National Roof Certification and Inspection Association (NRCIA)

The biggest downside of single-ply roofing options is that they’re more challenging to repair. Unlike a BUR, which a roofer can patch, repairing a single-ply membrane often involves a full roof replacement. The thinner materials also make them more likely to tear, so they have a shorter lifespan in areas that see extreme weather, like hurricanes, tornadoes, and tropical storms, which can blow damaging debris onto your roof.

The seams in your single-ply roofing are also potential weak spots that can lead to leaks, especially if UV rays damage the adhesives.

| Pros | Cons |

|---|---|

| Affordable | Tear easily |

| Minimal maintenance | Hard to repair |

| Long lifespan | Seems can leak |

Fixing a water leak makes up nearly half of flat roof repairs. Leaks are most likely to occur at the seams between roofing layers and can also happen when flat roofing is punctured during a storm. Contact a roofer to repair issues such as cracks, blisters, and clogged gutters as soon as possible.

There are a few types of single-ply roofing you can choose from, and the one that’s right for you depends on your climate and budget.

EPDM roofing is made from synthetic rubber. It’s black or dark gray, so it readily absorbs heat and can contribute to solar heat gain in your building. It’s prone to tearing, much like other single-ply membranes, although it’s the easiest of the three options to repair. Repair costs will, therefore, be more affordable than with other single-ply materials.

Fully adhered EPDM roofing is the most common, as mechanical fasteners create additional roof penetrations that increase the risk of leaks. Seaming requires using an adhesive and allowing it to cure.

An EPDM roof costs between $5 and $13 per square foot, making it one of the more affordable types of roof. The material also has an expected lifespan of 30 to 40 years, so it’s an affordable option in the long run, too. Just keep in mind that you’ll need to reseal the roof every five years or so to maintain its waterproof properties.

PVC roofing is common in residential flat-roof construction due to its durability and puncture resistance. PVC comes in rolls that are thinner than EPDM, making it easier to install due to maneuverability. However, thinner rolls means more seams, which can increase the risk of leaks. Luckily, your roofer can heat-weld PVC roofing seams for superior strength.

A PVC roof costs between $5 and $15 per square foot, making it the most costly option of the three. Labor costs affect the overall price due to more seaming than the other types. With that being said, PVC roofing also lasts the longest and provides the most long-term value, with the material lasting between 20 and 30 years with good maintenance. That maintenance includes resealing every 10 to 15 years, and you should regularly look for signs your flat roof needs to be replaced, including physical damage.

TPO roofing is the only one of the three that normally comes in white sheets. According to the U.S. Department of Energy, that makes it a cool roof that can reduce cooling costs in hotter climates. It’s the most energy-efficient roofing option of the three single-ply options.

The seams are heat-weldable, and it's resistant to UV rays. The material is available in narrow and wide widths of up to 20 feet, making it ideal for most applications, including residential and commercial buildings.

TPO roofing costs between $4 and $14 per square foot. It’s the most prone to tearing, so it isn’t ideal in areas that see extreme weather. It also has the shortest lifespan of the three, especially if it sees a lot of wear and tear from strong winds and blown debris, and it lasts from 15 to 30 years. It’s challenging to repair, too, so long-term costs will tend to be higher for this option.

Single-ply roofing costs an average of $7,500 to install, although the price will depend largely on the size of your roof and the complexity of the installation. You’ll pay between $4 and $15 per square foot, depending on the type you choose.

The cost is initially slightly higher than that of built-up roofing and modified bitumen, which cost between $4 and $10 and $4 and $8 per square foot, respectively. Over time, though, prices can be more affordable, as you’ll need less maintenance and fewer repairs.

Although rolled asphalt roofing is the less costly alternative for protecting flat roofs, in most cases, the cost evens out in the end due to rubber roofing’s longevity and superior protection. Single-ply roofing is worth the cost if you’re looking to prioritize minimal maintenance over up-front cost, and it’s especially an option worth considering if you live in an area that doesn’t see extreme weather that could threaten the material.

When deciding between single-ply and rolled roofing, consider factors like UV exposure, lingering moisture conditions, climate, and maintenance needs.

There are three different installation methods you can choose from for your single-ply roof.

Mechanically attaching the materials is the second most common way to install single-ply roofing. It involves using special fasteners drive down through the parts of your flat roof to attach the sheets to your roof decking below, and your roofer will then patch over each of the fasteners to avoid leaks through the penetrations. Mechanically fastening your single-ply roofing leads to the highest risk of leaks, but the installation is the most affordable.

Most professionals will use the fully adhered method of installation for single-ply roofing membranes. For this method, your roofer will use adhesives rather than fasteners to secure the sheets. Then, your pro will use adhesive or heat to seal the seams.

This installation process takes longer and is more costly than mechanically attaching the roof, but it leads to a lower risk of roof leaks due to fewer roof penetrations.

Another upside is that fully adhered roofs have higher Factory Mutual wind-uplift ratings, which means the roof can withstand higher winds.

Ballasted single-ply roofs aren’t attached with fasteners or adhesives. Instead, pros lay down the insulation and roofing materials and weigh them down with river-washed gravel or concrete pavers before sealing the seams around the perimeter. The ballasted method adds significant weight to your roof, so structural reinforcement may be necessary. This installation is quick, easy, and economical, with simple maintenance requirements.

Installing single-ply roofing as a DIY project can save you up to $4 per square foot over hiring a pro to do the work. However, this is a significant challenge that requires experience and specialized tools. Any mistakes can quickly lead to roof leaks, expensive water damage, and efficiency losses that can cost more than you’d save.

As such, this is a job you should leave to professionals. Hire a roofing company near you that specializes in the type of single-ply roofing membrane you’re looking to install. Not only will you end up with a roof that looks better and provides greater protection for your building, but your pro will also pull the necessary building permits, take care of removing your old roof, and provide a warranty to give you greater peace of mind.

From average costs to expert advice, get all the answers you need to get your job done.

Getting a wind mitigation inspection can work in your financial favor. Learn about the average wind mitigation inspection cost, including ways to save.

Let the light flood into even the gloomiest attics and transform the look of your home. Here's how to calculate the cost of adding a dormer of any style.

Metal shake roofs offer a long-lasting alternative to asphalt shingles. Learn what metal shake roofs cost and what factors affect how much you’ll pay.

Dreaming of a tile roof but not in love with how expensive clay tiles are? Concrete tile roof costs are much lower, but you still get that classic look.

Protecting your metal roof starts with the right roof insulation. Learn about the best underlayment for metal roofs to increase longevity.

Choosing the right roofing material can help your home stand up to snow, ice, and harsh winds. Learn more about the best roofing materials for cold climates.