How to DIY a Shiplap Fireplace to Refresh Your Space

Warm up to the hottest design trend

- Stud finder

- Pencil

- Measuring tape

- Miter saw

- Hammer

- Two-by-four wood boards

- Common or framing nails

- Shiplap planks

- Shiplap trim

- Finishing nails

Maybe your living room has an empty wall that’s begging for a refresh, or perhaps you have a stone-clad fireplace that you want to bring into modern times. When combined with a fireplace, shiplap can make any room feel fresh yet timeless. Transform your living room in a weekend by installing a DIY shiplap fireplace with this guide.

Buying Shiplap for a Fireplace

Before you start building your shiplap fireplace, you’ll need to determine how much shiplap to buy. You can do this by measuring the length and width of the area you plan to cover, then multiplying the two numbers. Then, divide that number by the width of your preferred shiplap planks to determine how many planks you need.

You can expect to spend around $2.50 to $7 per square foot for shiplap planks. Buy 10% to 20% more shiplap planks than you calculated. This will cover you in case of miscalculations or mistakes during construction because even the most experienced DIYers make mistakes every now and again.

Mark the Walls or Existing Fireplace

First, you’ll need to mark out where the shiplap will go. If you’re installing an electric fireplace, you’ll also need to mark where the fireplace will go. Use a stud finder to mark where the studs are located in the wall (and the rafters in the ceiling if you are building a frame all the way up the wall). Use a measuring tape and pencil to detail where you’ll install the frame.

Build the Frame

Shiplap is a type of wood plank that needs a sturdy frame to nail into for stability. The frame should be installed so that the two-by-four wood boards of the frame are attached to the studs and rafters you marked previously. The size of the frame will depend on how far out you want to extend the shiplap. Use a miter saw to cut the two-by-four wood boards as needed to fit into your design.

Install the frame by using a hammer or nail gun and common nails or framing nails to attach the wood boards to the studs and rafters as marked. If you’re installing an electric fireplace rather than covering an existing fireplace exterior in shiplap, make sure to frame out a space for the new fireplace.

Cut Shiplap Planks

Photo: Westend61 / Getty Images

Photo: Westend61 / Getty ImagesWith the frame in place, you can start preparing for shiplap installation. Shiplap is characterized by long wood planks rather than shorter pieces, so measure the width of the fireplace frame to determine how long to cut the shiplap planks. You’ll need shorter planks to surround the fireplace opening and the sides of the frame. Use a miter saw to cut the shiplap planks to size.

Attach the Shiplap

With the shiplap cut to the right sizes, you can use a hammer or nail gun and brad nails to attach the shiplap to the wall at the stud marks or the frame. Start from either the top of the fireplace or the bottom, working from left to right until each board is attached to the frame or wall and ceiling. Use a level to make sure the first plank you establish is evenly aligned with the wall.

When you get down to your last shiplap plank, you may find that the entire plank is too tall to fit the remaining space. If that’s the case, measure the amount of space you need to fill, then use the saw to cut along the plank horizontally to that size. Use brad nails to attach the final plank.

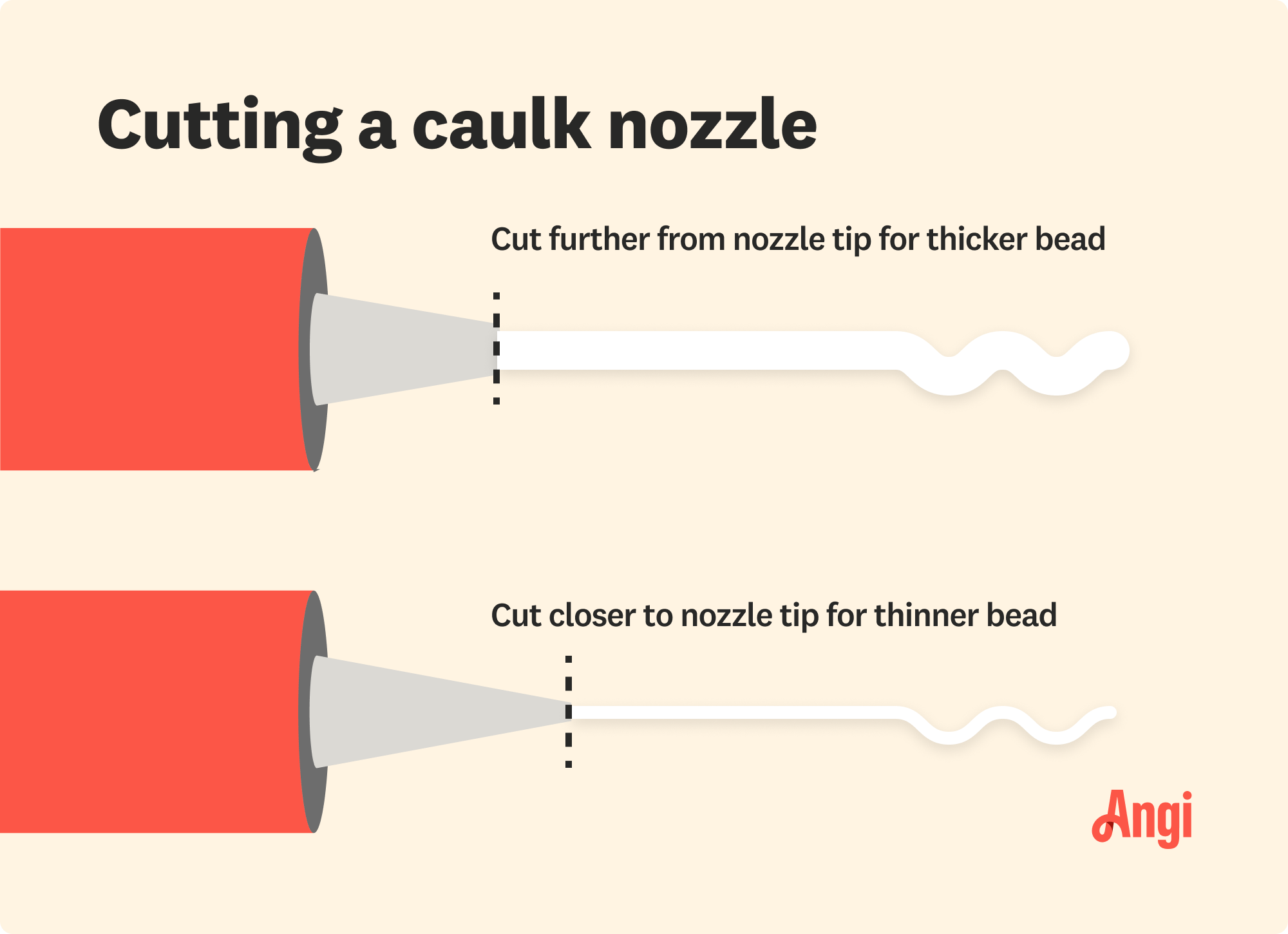

Caulk Between the Lines

If you want the classic, seamless look of shiplap, use caulk between the boards. Give the caulk time to dry, which could be as little as 30 minutes for silicone or acrylic latex caulks or up to 24 hours for polyurethane-based caulk. Always follow the manufacturer’s instructions.

Paint the Shiplap

Maybe you want a chic, black shiplap fireplace, or perhaps you’re looking for the perfect shade of creamy, off-white. If the natural color of your shiplap isn’t to your taste, you can use a paint roller and a small paintbrush to apply primer and a paint of your choosing. If you’re installing an electric fireplace, which doesn’t generate as much heat as open flames or gas, you can use standard paint. Otherwise, opt for heat-resistant paint.

Let each coat of primer and paint dry for at least two to six hours before applying a new coat or moving on to fireplace installation or trimming.

Install the Fireplace (If Needed)

Photo: PC Photography / iStock / Getty Images Plus / Getty Images

Photo: PC Photography / iStock / Getty Images Plus / Getty ImagesIf you don’t already have a fireplace that you’re surrounding in shiplap, you may opt to install an electric fireplace to create a cozy centerpiece in your living area. If so, you should have established a wood frame within the larger fireplace frame for the electric fireplace to sit. Following the electric fireplace instructions for installation, set the fireplace into the frame you built, and make sure you can easily access the power cord. You may need to build an additional panel or cut into the shiplap for easier access to the power cord.

If you get confused about the installation or need help with the power for your electric fireplace, take a break from the project and call an electrician for help before moving forward.

Add Finishing Trim

The shiplap is installed and perhaps painted, but it may not look complete just yet. You’ll need to add trim around the base, edges, and top of the fireplace. You can use finishing nails on the trim for a seamless look.

Add a Mantel

Photo: hdere / iStock / Getty Images Plus / Getty Images

Photo: hdere / iStock / Getty Images Plus / Getty ImagesFor a finishing touch, consider installing a mantel. You can use floating shelf brackets if you don’t want to see the supports, or you can use metal or wood brackets for an industrial or rustic look. You can buy a prefabricated mantel to save extra time and effort or choose new or reclaimed wood boards or beams that you cut, sand, and stain for a unique, custom appearance.

DIY vs. Hiring a Fireplace Pro

Hiring a local fireplace installer is the best option for creating a shiplap fireplace. A pro can achieve a sleek, even, and attractive appearance, so you won’t have to spend several days’ worth of labor on the project. Not only will the pros make sure the project looks great and is done quickly, but they can also confirm that your updated fireplace meets local building and safety codes.

Frequently Asked Questions

If you already have the tools, like a miter saw, a stud finder, and a nail gun or hammer, installing shiplap costs $500 to $1,000 for supplies. You’ll also spend $200 to $2,200 for the cost of an electric fireplace if you decide to add one into your setup.

You can also hire a carpenter for $35 to $100 per hour, plus the cost of materials, to install shiplap around your fireplace. If you need help installing a fireplace before adding the shiplap, labor can cost $225 to $2,180 for fireplace installation costs.

It’s less costly to drywall a fireplace than shiplapping it since material costs are higher for shiplap. However, if you’re DIYing the project, shiplap is less expensive since you won’t have to pay for labor. With drywall, getting a smooth finish is difficult unless you’re a pro. Shiplap is ideal for an accent wall or unique space, such as around a fireplace, since it adds texture and gives off a cozy vibe.

Shiplap can be safe for a gas fireplace, but you should consult with a fireplace installation pro before proceeding. You need to make sure your project meets building and safety codes since shiplap is made from flammable wood. You may need to install another non-combustible material, like stone or brick, around the fireplace for a certain amount of space before you can add shiplap.

You should caulk between shiplap for a cleaner, more seamless look. It’s not required, but it can help your project look more cohesive and complete. Apply a thin bead of acrylic latex caulk along the line between two boards of shiplap and allow it to dry completely before doing more construction work or painting over the shiplap planks.