Discover cabinet installation cost estimates, including average prices, key cost factors, and tips to save on your new kitchen or bathroom cabinets.

Prepare for your remodel by learning the language of cabinet designers

Cabinets either have face frames or are frameless.

They’re often made with solid wood, plywood, MDF, or particleboard.

Door style options include raised panel, shaker, mullion, and slab.

Popular finishes include paint, stain, melamine, and thermofoil.

New cabinets are a major investment that can add to the value of your home. You’ll want to choose cabinets that not only look good but also function well, because you’ll use them every single day. Before you walk into a cabinet showroom or start browsing online, it’s a good idea to familiarize yourself with cabinet terminology so you can more easily communicate what you want. This guide will give you the language you need to describe cabinet types, different components, common materials, and finish options so you can start designing the cabinets of your dreams.

As you begin to shop for new cabinets, you’ll come across cabinet terminology that describes the different types of cabinets on the market today.

Stock cabinets are mass-produced in common sizes and a limited array of styles, colors, and finishes. They’re the most affordable with fast delivery and installation times.

Semi-custom cabinets are similar to stock but with a limited selection of made-to-order features like custom shelves, racks, organization inserts, molding, and more.

Custom cabinets offer the most in terms of quality and options. Work with a designer to fit your needs exactly and create a unique cabinetry solution.

Also called lower cabinets, these mount along the baseboard to provide a sturdy base for countertops, islands, seating, and more. The bottoms of doors open a few inches from the floor.

At eye level or higher above countertops, you’ll find wall-mounted upper cabinets. These are ideal for storing items you may need to access while standing or moving about, such as dishware and spices. If located above a stove, sink, or fridge, they’re often called bridge wall cabinets.

Also known simply as tall cabinets, these provide extra height for storing everything from bulk food items to mops and brooms. You can also design them to accommodate small appliances such as microwaves.

If you have a corner where two cabinets meet at a right angle, a blind corner cabinet can help to maximize the space. You’ll often find a rotating circular shelving unit called a lazy susan within.

Also known as face frame cabinets, these cabinets have frames on the fronts of their boxes that are typically between 1 ¼ to 2 inches wide. Face frames provide strength and stability and are also what door and drawer fronts are attached to. Face frames are more commonly used in American cabinet design than in European design.

Whereas American cabinet makers traditionally use face frames to provide strength, stability, and aesthetic appeal, European cabinetry is known for its sleek, frameless design aesthetic. Frameless cabinets do not use face frames; instead, doors and drawers are mounted directly on the cabinet box. Most designs also forgo the center stiles between two cabinets.

While not always as sturdy as framed cabinets, frameless designs offer increased accessibility by widening the storage space opening.

Many framed cabinets use a partial overlay design, meaning that a portion of the face frame remains visible even when the doors are closed. Partial overlays most commonly leave 2 inches of space around the entire face, though designers may leave more or less depending on the aesthetic they wish to achieve.

These cabinets are some of the most forgiving designs for amateurs to install because the pieces do not have to be precisely matched.

With full overlay designs, the closed doors and drawers completely cover the front of the cabinet. While all frameless cabinets are full overlay, not all full overlay cabinets are frameless, so homeowners can enjoy the sleek look of a full overlay design while benefiting from the face frame’s additional support. These cabinet doors and drawers must be installed precisely or the gaps will be noticeable, so it is often best to work with a pro if you want a full overlay design.

In partial and full overlays, the doors and drawers rest on the cabinet frame or box when closed, but with inset cabinets, they rest completely flush inside the face frame. Homeowners seeking the strength of framed cabinets and the sleek look of frameless designs often appreciate the look of inset doors. These designs usually require some kind of hardware, such as knobs or pulls, to open doors and drawers, though some systems utilize a push-opening system to maintain a fully smooth face.

Of all cabinet door-hanging options, inset is the hardest to install because the doors and drawers must be aligned perfectly in the cutout and sit flush with the face frame.

Once you start researching options for new cabinets, you’ll see a world of cabinet components that you may have never considered. Below are the main parts of a cabinet.

These terms refer to the entire body of the cabinet, including the back, sides, top, and bottom. Similarly, a drawer box creates the shape of a drawer but with an open top.

The most prominent part of the cabinet is the visible front of the door or drawer. You’ll likely put the most effort into choosing the perfect style, color, finish, and hardware for this front-facing element. Some door style options include:

Raised Panel: A traditional look with a decorative raised center.

Recessed Panel: A solid frame surrounds a flat center panel. Also called shaker style, it’s a popular and versatile look.

Mullion: A unique look with no center panels. Sometimes gridded in the center, they’re intended to have a glass door insert.

Slab: A frameless door style made from one slab of material, popular in modern and contemporary designs.

In cabinet nomenclature, the horizontal parts of a door or frame are known as rails. One rail is at the top, and one is at the bottom of the door or frame.

The vertical portion of a cabinet door or frame is called a stile. While frames typically only have two rails (one at the top and one at the bottom), they often have three stiles: one in the middle and one on each side. While center stiles can add to the aesthetic appeal of a cabinet, they can make it more difficult to access items in the cupboards.

The front-facing portion of a framed cabinet where the doors and drawers are mounted is called the face frame. It reinforces the cabinet box and is usually made of two horizontal rails and three vertical styles. Even when the cabinet box is made from engineered wood, the face frame is often made from solid wood to increase the cabinet’s overall look and strength.

These are the hardware that connect your cabinet door to the cabinet box, allowing said door to swing open and close. Common types of cabinet hinges today include sleek concealed options, which are not visible on the front of the cabinet door, but you’ll also find some stylish exposed hinges. Hinges that are adjustable make it easy to keep doors and drawers in alignment.

Also known as slides, these are runners that allow a drawer to open and close. They have to be incredibly strong so as not to collapse under the weight of a drawer’s contents—which, in a kitchen, can include pounds of heavy silverware. Glides can be undermounted or side-mounted; if they are full extension, they’ll allow you to open the drawer all the way. Avoid loud slams when shutting drawers with soft-close drawer glides that catch and slow drawers before they hit.

Fixed shelves are built into a cabinet during the construction process and cannot be moved. While they are sturdier and can hold more weight than adjustable shelves, fixed shelves can be inconvenient when someone wants to store objects that are too tall for the storage space. They often work best for cabinets designed to hold items of standard height, such as mugs or dish sets.

Adjustable shelves are most commonly held in place using movable pegs that are fitted into one of a series of holes on the sides of the cabinet. This design allows them to be raised or lowered to accommodate items of different heights. While convenient, adjustable shelves are only as strong as the pegs and the holes in the cabinet base.

Some base cabinets will have a recessed bottom area or cutout that allows more room for your feet when approaching or standing in front. This feature is especially useful in front of sinks or countertops where you’ll need to get close.

Wondering how to hide large appliances in your kitchen so they blend in with the rest of your cabinetry? Ask your contractor about a dishwasher, microwave, oven, or refrigerator overlay panel. Appliance and cabinet manufacturers frequently sell these products to match cabinets, creating a seamless appearance, but they can also be custom-built by a local cabinet maker.

As you explore your cabinet options, you’ll find that manufacturers use various materials to build their products. The quality of the materials will play a big role in the overall cost of your cabinets. Here are some of the most common types:

It’s rare for cabinets to be 100% solid wood; usually, the cabinet boxes are made with plywood, MDF, or particleboard (see below). Cabinets described as solid wood typically have door and drawer fronts, face frames, and trim made from solid hardwood species like oak, maple, cherry, and hickory.

Layers of medium to softwood are glued together with grains running at different angles to form this strong building material. Plywood is the material of choice for the boxes of better-quality cabinets; in high-end cabinets, the plywood is ¾ inch thick. Plywood is often used for shelving as well, and it’s sometimes used for door and drawer fronts, too.

MDF is another engineered wood product made from fine wood fibers and glue, fused under heat and pressure. Strong and relatively inexpensive compared to natural hardwood, MDF does not expand or contract with humidity changes.

Made from a fusion of sawdust or wood chips and glue bonded under pressure, particleboard is not as strong as MDF but is slightly more affordable.

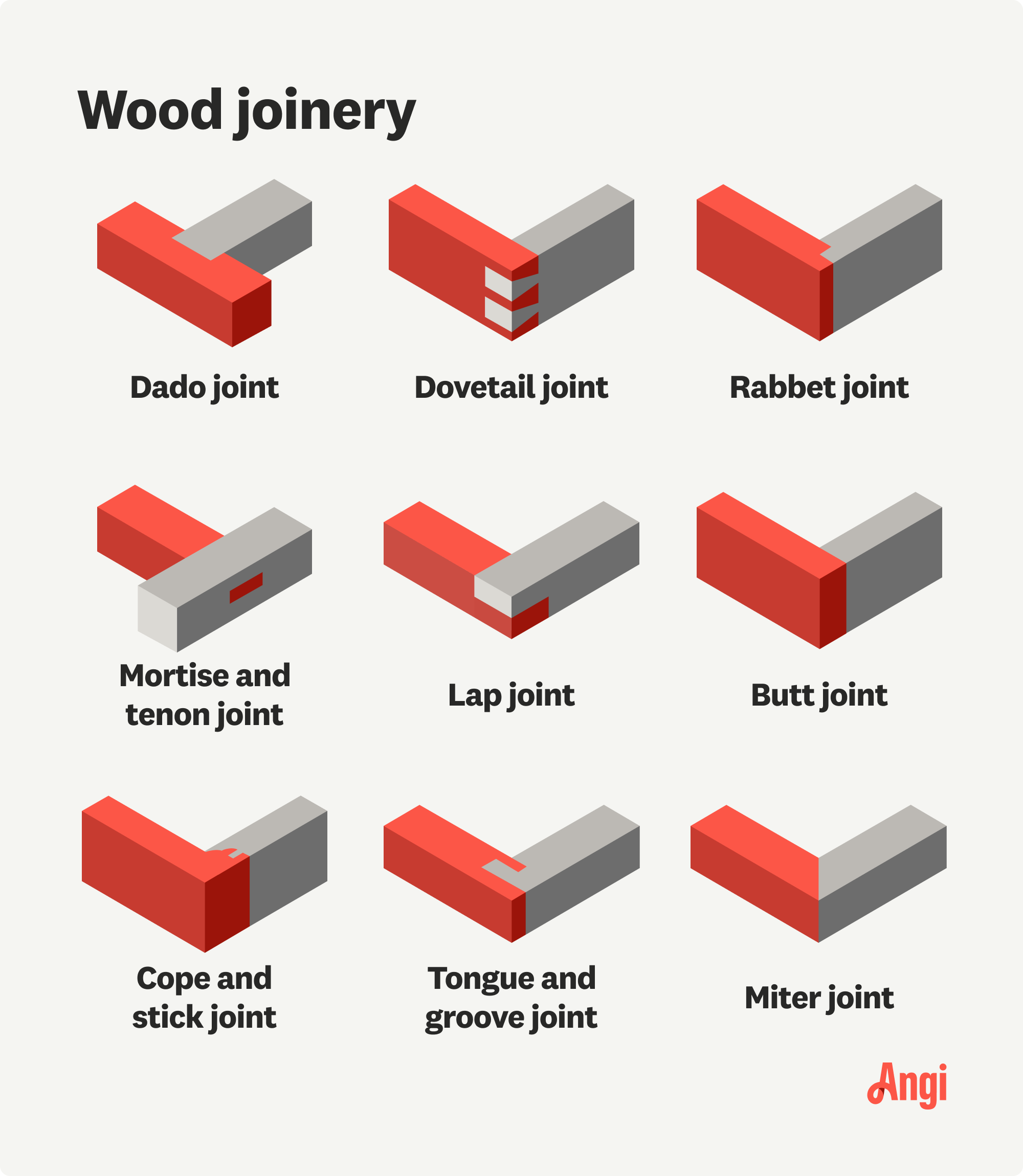

In woodworking, joinery is the process of securing two or more pieces of wood together. Around 46 types of joints are used in cabinetry, and each type bonds the materials together in a slightly different way with varying levels of durability and differing aesthetic properties. Some of the most common include:

A dado joint is made by cutting a groove into a piece of wood and then placing another piece perpendicularly into the channel so it is snug and secure. In most cases, these joints are both glued and nailed, creating a very strong joint ideal for holding a lot of weight.

These interlocking joints consist of trapezoidal pins that fit into the “tails” between the pins on a second piece of wood. Dovetail joints have been used for centuries because they function well even without glue. In modern times, most cabinet makers secure these joints with glue, but they are never nailed.

Because these joints resist wear from pulling, they are ideal for adding durability to drawer boxes. Their attractive appearance can also enhance the beauty of furniture and cabinets, making them one of the most popular joint types.

In woodworking, a rabbet is a recess cut along the edge of a board. When making a rabbet joint, also called a half-lap joint, the cut should be the width of the adjoining piece. These joints are stronger than simply gluing two boards together because they increase the surface area for glue. A double rabbet joint is an even sturdier connection wherein a rabbet is cut into each adjoining board.

A mortise is a groove cut in a piece of wood, while a tenon is a peg. The resulting joint is created when the two are secured together, typically with glue, but occasionally with a nail, pin, or screw as well. Mortises and tenons can be different shapes, most commonly squares, rectangles, or circles. In cabinetry, tenons are often added to the end of rails.

When two pieces are connected by overlapping, they form a lap joint. The four most common types of laps used in woodworking are the half lap (rabbet), mitered half lap, cross lap, and dovetail lap. Each lap has unique benefits, so cabinet makers need to use their best judgment on which will be the most appropriate for a particular situation.

Unlike a lap joint, where two pieces of wood are placed over one another, a butt joint is made by simply gluing or screwing the ends of two pieces of wood together perpendicularly. These joints are not very strong, so they are not frequently used in cabinetmaking.

Sometimes called a stile-and-rail joint, this joint method uses mortises and tenons to secure the molded edges of cabinet doors. While more attractive and sturdier than a square edge, forming these intricate joints requires advanced carpentry experience, meaning that adding them will often dramatically increase the budget of a cabinet system.

Tongue and groove assembly is made by cutting a long groove into one piece of wood and a protruding “tongue” in another piece that slips into the groove. This type of joint does not require any fasteners, though glue can help secure the pieces in place. These joints are very strong and cope well with wood expansion due to fluctuating humidity, but they are time-consuming to make, so carpenters often prefer using other joints.

A miter joint, sometimes spelled mitre, is similar to a butt joint, only rather than placing the two wood pieces perpendicularly, they are cut at precise angles, usually 45 degrees. The two pieces are then glued, nailed, pinned, or screwed together.

A cabinet’s finish is for more than just looks: it also protects from wear and tear.

Unfinished cabinets feature completely raw wood. They’ll need to be sealed to preserve the appearance of their natural wood grain—the natural swirling rings and lines in the wood.

Paint provides a solid-colored layer of protection for cabinets. One advantage of paint is the practically limitless array of options available. Match the rest of your decor with complementing or contrasting paint colors.

Wood stain is a more natural-looking option for protection, absorbed by the wood to provide benefits such as waterproofing. Stain can be solid, semi-transparent, or transparent to allow the natural grain to show through.

Distressing refers to methods of finish that appear slightly damaged for a time-worn, antique look. Techniques include rubbing, glazing, burnishing, wire-brushing, and more.

Wood veneer refers to thin sheets of real wood that get glued to a substrate such as MDF. This material can provide you with the appearance of solid wood cabinets at a lower cost.

Melamine, like veneer, is fused to a substrate. Instead of wood, however, it’s made from plastic in a near-endless assortment of colors and patterns.

Thermofoil is a thin layer of vinyl that’s vacuum-sealed onto a substrate. The surface is easy to clean and comes in a vast array of colors and patterns.

Also important to note is the interior finish material you choose. You’ll want all interior surfaces, including shelves, to be non-porous so they can easily wipe clean. Common options include melamine, laminate, and veneer in light wood tones that make the cabinet’s contents easy to see.

Molding is the trim placed along the edge of a cabinet, where it meets the floor, ceiling, walls, or other cabinets. It can be very simple, or it can feature ornate, decorative carvings. Different molding types most commonly used in cabinetry include:

This term refers to trim that’s used on the tops of cabinets. Adding toppers to cabinets improves their appearance by providing an interesting transition and reducing gaps at the top of the cabinet box.

More commonly known as a baseboard, base molding is applied at the bottom of the cabinets where they meet with the floor. Baseboards add visual interest while also protecting the bottom of the walls and cabinets from damage.

Often called a filler strip, this type of molding covers gaps around a cabinet. Sometimes, fillers can increase the functionality of a cabinet system. For example, they allow a cabinet box to be spaced further from the wall so the door doesn’t bonk against the wall.

Filler strips can be simple, beaded, or fluted, but they should be made from the same material and same finish as the rest of the cabinet. While they are sold in standard pre-made sizes, cabinet makers often make their own strips for the specific project.

Scribe molding is a thin, flexible piece of finished trim that can cover any gaps, seams, or raw edges after installation. Because it is flexible, it works well to seal gaps along uneven surfaces, such as slightly curved ceilings or floors, so it is often applied to the top of crown molding or the bottom of toe kicks.

Rope molding is a type of molding featuring a pattern resembling strands of a rope.

Dentil molding is a kind of molding that features a decorative square pattern, somewhat resembling teeth.

According to responses from 10,400 Angi customers, drawers are a common source of cabinet issues, with 25% of repair requests focused specifically on them. Cabinet doors and their components are also frequent concerns, with 21% of homeowners requesting door repairs and 18% needing hinge repairs. These findings underscore the importance of regular maintenance and high-quality materials to ensure cabinets remain fully functional.

From average costs to expert advice, get all the answers you need to get your job done.

Discover cabinet installation cost estimates, including average prices, key cost factors, and tips to save on your new kitchen or bathroom cabinets.

Choosing new cabinet hardware is a fun balance of practicality and design. Costs range between under $100 and up to five figures, though, so budgeting and knowing which materials you can afford is key. This cost guide breaks it all down.

The cost to replace the bottom of kitchen cabinets often isn’t too high, but depending on the damage, a full cabinet replacement can cost thousands.

There are many types of cabinet hinges, but the ones you can choose from will depend on the construction of your cabinets. Learn more here.

Picking the right handle or knob isn’t difficult if you know a bit about the most common kitchen cabinet hardware styles.

When upgrading your kitchen, compare inset vs. overlay cabinets. Here’s what you should know about the differences between the two constructions.