How to Test an AC Capacitor and Cool Down Your Home Faster

Keep cool and test your AC capacitor

- Multimeter

- Screwdriver with a plastic or rubber-insulated handle

Few things are as unnerving as the sound of a struggling air conditioner during a blistering heat wave. There are a lot of AC parts that can fail as your system tries to battle the summer heat, and one of those is the AC capacitor. You can learn how to test an AC capacitor on your own, but since these devices carry a high charge, you shouldn’t attempt the task unless you already have a solid HVAC background. It’s always safer to get in contact with a pro if you think your AC capacitor is causing problems.

Gather Your Tools

To test an AC capacitor, you’ll need a multimeter, a tool used to test the voltage, current, and resistance in electrical devices. A multimeter is a small handheld device with a dial, two probes, and a digital display.

These devices cost between $10 and $50 and are available at most home improvement stores. Make sure you purchase one that allows you to test the capacitance, which is the ability to store an electric charge.

You’ll also need a screwdriver with a plastic or rubber-insulated handle.

Cut Off the Power

Since you’ll be working with an appliance that uses high voltage, it’s important to take the proper precautions to minimize the risk of electric shock—including cutting off power at the breaker before you begin.

To do this, locate the breaker on your home’s electrical panel. Cut the power to the AC unit to ensure no electricity is flowing through it while you’re testing the AC capacitor. A central AC unit will be on one of the panel’s 230-volt breakers.

Locate the Capacitor

Using a screwdriver, remove the access panel on your air conditioning unit. The capacitor should be easy to spot. It’s silver, cylindrical, about the size of a soda can, and has wires of various colors connected to it.

Release the Charge

Since an AC capacitor stores an electric charge, you’ll need to release that energy before you can safely work on it to eliminate the risk of shock. Use the metal end of your screwdriver to connect the capacitor’s electrical terminals to each other to release the charge.

Make sure you use a screwdriver with a plastic or rubber-insulated handle and don’t allow your hands to come into contact with any exposed metal on the screwdriver while you’re releasing the charge in the capacitor.

Remove the Capacitor

Now that you’ve discharged the capacitor, you can safely remove it from the AC unit. Begin by taking a picture of the wiring, so you can reinstall the capacitor after testing or replacing it. Next, unplug each of the wires connected to the capacitor, then unscrew the brackets holding the capacitor to the air conditioner and pull it out.

Check Its Condition

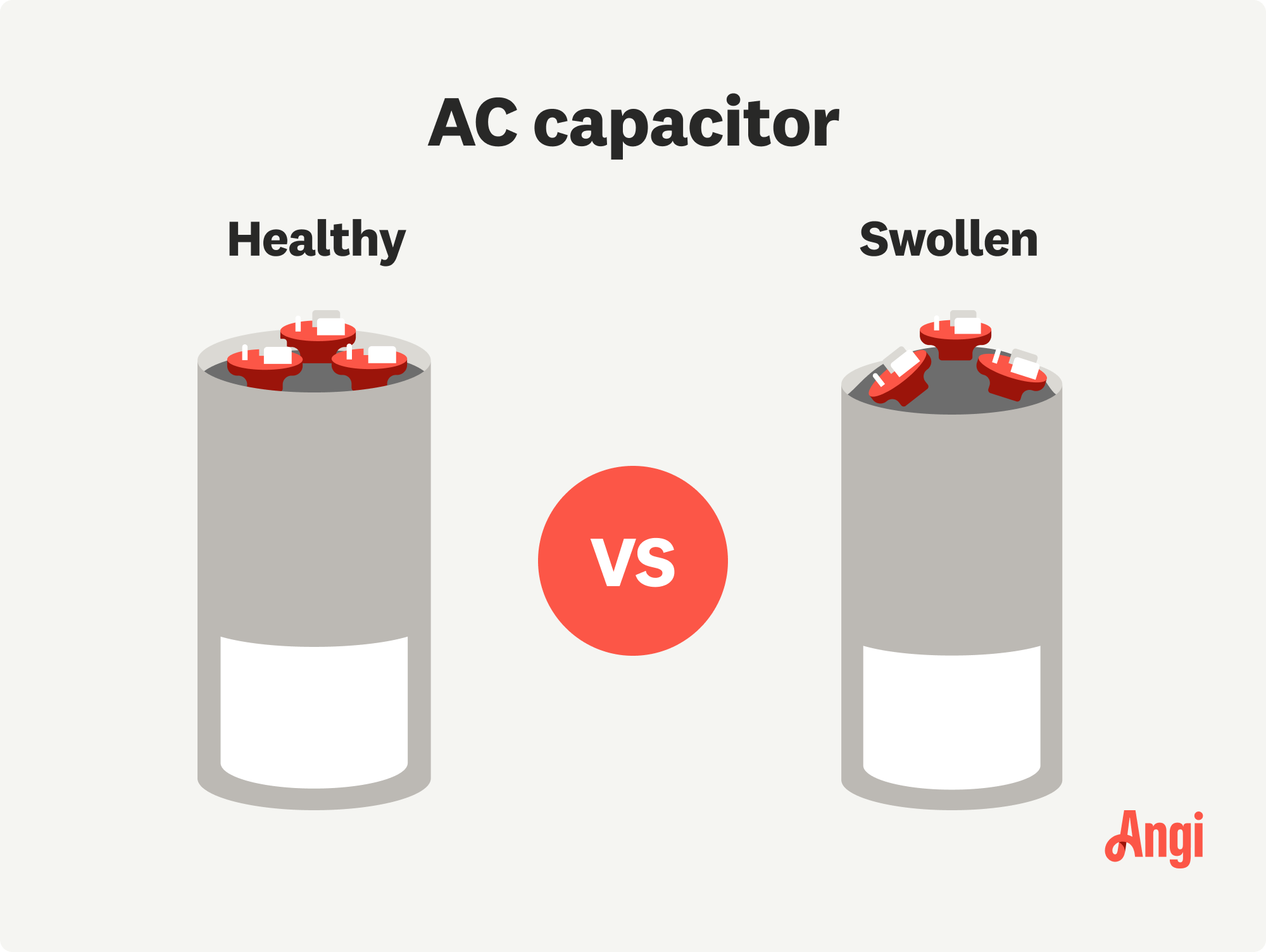

Before testing the capacitor, visually examine it. When a capacitor fails, it often bulges or leaks. If your AC’s capacitor has either symptom, you’ll need to replace it.

Identify the Capacitor’s Rating

You’ll need to know what you’re looking for before you can test your capacitor. Check the capacitor’s label for its microfarad (MFD) rating, which is a measurement of the amount of electricity the capacitor can store.

If you’re testing a single capacitor, you’ll find a single microfarad rating on the label. Dual capacitors have two microfarad ratings; the higher rating is for the compressor while the lower rating is for the fan motor.

Next to the microfarad ratings, you’ll also see a percentage on the label with a plus and minus sign. This percentage tells you how far off the listed microfarad ratings the capacitor can be and still function properly. For example, a capacitor with a rating of 25 microfarads and a plus or minus rating of 5% will have readings between 23.75 and 26.25 microfarads on the micrometer if it’s functioning normally.

Set Up the Multimeter

Turn the dial on the multimeter to the setting for capacitance. Most multimeters use the symbol –|(– to signify capacity. You should also see a uF symbol on the display, which stands for microfarads. If you’re not sure which setting on the dial to use, consult the multimeter's instructions for how to find the setting for testing capacitance. After you have the multimeter dialed in, plug the two probes into the meter’s outlets.

Test the Capacitor

How you test the capacitor varies depending on whether you have a single capacitor, which only has two terminals, or a dual capacitor, which has three terminals.

1. Testing a Single Capacitor

Place the first probe on one of the multimeter’s terminals and the second probe on the other terminal, then check the meter’s digital display. Compare the reading to the rating on the label to see if it's functioning normally. Don’t forget to account for the margin of error percentage.

2. Testing a Dual Capacitor

A dual capacitor provides a power boost for both the fan and the compressor and has three terminals. One terminal will be labeled “C” for common terminal, another labeled “FAN” for the air conditioner fan motor, and a third labeled either “HERM” or “COMP” for the unit’s hermetic compressor.

Start by testing the fan terminal by connecting one probe to the common terminal and one to the fan terminal. Next, test the hermetic compressor by placing one probe on the common terminal and the other on the hermetic compressor’s terminal.

Again, compare the readings to the rating on the label to see if the capacitor is functioning normally. If either the rating for the fan or compressor is off by more than the percentage listed on the capacitor label, you’ll need to replace the capacitor.

How to Tell If an AC Capacitor Is Bad

Most people discover a failed AC capacitor when it stops working.

However, there are ways to tell if an AC capacitor is nearing the end of its life before it leaves you high and dry. If you observe any of these AC issues, test your capacitor before it’s too late.

Dimming lights: If the AC capacitor is failing, you may experience dimming lights every time the AC unit kicks on. This means the capacitor is struggling to provide enough juice to power on the fan or condenser, forcing your home’s electrical system to work harder to get the AC started.

Humming noise: If you turn on your AC and you hear a humming noise and the unit hesitates to start, your capacitor may be nearing the end of its life.

No cold air: If your AC fan is running, but it’s not cooling the air, then the capacitor likely isn’t producing enough power to start the compressor.

AC sometimes won’t turn on: An air conditioning unit that sometimes fails to turn on is a clear sign of an aging AC capacitor.

Rising energy bills: An AC capacitor that isn’t functioning properly will put more strain on the air conditioning system, causing it to use more electricity.

DIY vs. Hiring a Pro

You should hire an HVAC technician to test and replace the AC capacitor on an ailing air central air conditioner. Though testing an AC capacitor is relatively simple and doesn’t require any special tools beyond a basic multimeter, it can be dangerous for someone with little to no experience working on HVAC systems.

Since the bulk of AC and HVAC repair costs comes from labor, there’s good reason to take this repair job on yourself. You’ll spend between $5 and $75 for the replacement capacitor. A local HVAC repair pro will cost you an additional $75 to $200 in labor to install the part.

While the air conditioner’s fan may continue to run, an air conditioning unit needs a capacitor in order to supply the power needed to start up the unit and cool your home. If your air conditioner has a bad capacitor, it will stop running, and you’ll hear a humming sound coming from the unit.

AC capacitors typically last for a long time and many last for the life of the air conditioning unit. You can expect to get about 20 years out of an AC capacitor. When an AC capacitor suffers an untimely death, it’s usually due to overheating, a power surge, or a short circuit. You can prevent these events from happening and extend the life of an AC capacitor by getting regular AC maintenance every year.

You can buy a new AC capacitor through most big-box home improvement stores, from an HVAC contractor, or from the manufacturer. Use the model number of your air conditioning unit to make sure you purchase the right part for your unit. Also, keep in mind that the cost of this type of part can vary significantly depending on who you purchase it from, so shop around to get the best price.

When shopping for a multimeter to handle this job, make sure you purchase one that is able to test for capacitance. While most multimeters offer this function, some do not. You shouldn’t have to spend a lot of money to find the right multimeter. There are models that can perform this test that cost as little as $10.

- Furnace Repair

- Air Conditioning Repair

- HVAC Repairs

- Furnace Installation

- Wood & Pellet Stove Repair

- Dehumidifier & Humidifier Repair

- Heat Pump Companies

- Swamp Cooler Repair

- Wood Stove Services

- HVAC Companies

- Commercial A/C Repair

- Geothermal Installation

- Air Conditioning Installation

- Boiler Repair

- 24 Hour Furnace Repair

- Geothermal Repair

- Heat Pump Repair

- Humidifier Installation

- Thermostat Repair

- Thermostat Installation

- Nest Installation

- Heating & Cooling

- Heating Repair

- Furnace Cleaning

- Furnace Tune-Up

- HVAC Technicians

- Subcontractors

- Furnace Maintenance

- Plumbing & Heating Companies

- Wood Stove Inspection

- Mini Split Installation

- Wall Heater Repair

- Duct Installers