How Can You Tell If a Vacuum Breaker Is Bad?

Learn the signs of a failing PVB before it leads to contaminated drinking water

A pressure vacuum breaker stops non-potable water from backing up into drinking water.

Two valves help regulate air and water pressure.

If air pressure gets too high, the breaker opens to prevent negative pressure and backflow.

A failing breaker may leak water or slow water flow from faucets.

The interior parts of the PVB need to be replaced about every five to 10 years.

When you’re outside watering the garden with a hose, you’re probably not thinking about whether the water you’re using for irrigation could back up into your home. That’s all thanks to your pressure vacuum breaker (PVB), an often little-known part of your home’s sprinkler system that has a big job: to keep your drinking water free of contamination. But what is this part, how does it work, and most importantly, how can you tell if a vacuum breaker is bad?

What Is a Pressure Vacuum Breaker?

The pressure vacuum breaker, or a type of backflow preventer, is one of many parts of a sprinkler system that helps prevent water backflow from an outdoor faucet from contaminating the water that flows in your indoor faucets, including drinking water.

From time to time, the water pressure in a home’s water supply can change. For instance, if the fire department opens up a nearby fire hydrant or the city water supply is disrupted, it can lead to negative pressure that can then cause non-potable water to flow back into your home and into the drinking water supply.

Instances like this are uncommon, but the pressure vacuum breaker helps prevent the backflow with a valve that opens up when air pressure increases to relieve some of the pressure.

Signs a Vacuum Breaker Is Bad

The pressure vacuum breaker parts will wear out over time, which can cause the device to fail. Some common signs to look for when a pressure vacuum breaker is failing include:

Dry or Brittle Seals

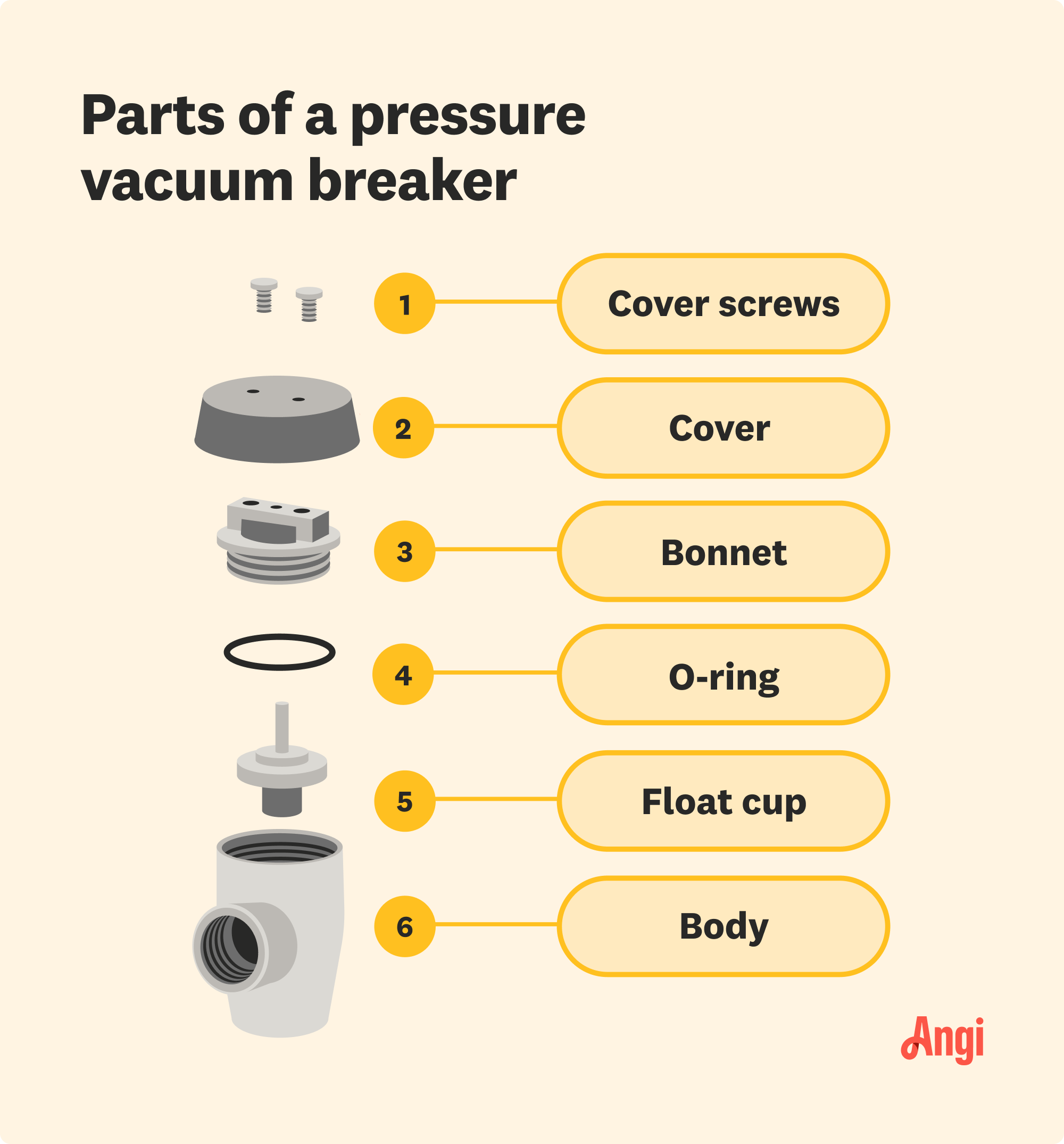

One common way to tell if a vacuum breaker is bad is by looking at the o-ring, or seal, around the pressure vacuum breaker. This part is made from rubber, which can dry out and become brittle.

Replacing the seal helps ensure your pressure vacuum breaker is operable if the pressure changes, but make sure to hire a sprinkler repair pro near you to install the new gasket. It has to be installed perfectly to prevent water leaks or breaker failures that could contaminate your water.

Leaks

Often, if parts of the pressure vacuum breaker are in need of replacement, the device will cause leaks around the outdoor water spigot. This can happen when dry seals crack, or if the o-ring isn’t installed correctly. Other parts of the vacuum breaker, like the poppet and bonnet, can wear out over time and cause water to leak out of the cap that conceals the pressure vacuum breaker.

Just keep in mind that leaks aren’t always a sign of a bad vacuum breaker, as they could mean there is another issue with your plumbing, like a cracked pipe. Be sure to have a plumber come inspect your home to find the source of any leaks.

Slow Water Flow

You turn on the kitchen faucet, and it seems to take forever to fill up your water bottle. What’s going on? If the pressure vacuum breaker has parts that are wearing out, it may not be able to properly relieve pressure through the air inlet valve. Aside from putting your drinking water at risk of contamination, the higher air pressure can make the water flow slower.

Like with leaks, there are several common plumbing issues that can cause changes in your water pressure, not just a bad vacuum breaker. Partially closed main shutoff valves, a leaking pipe, or corroded pipes can also be causes of low water pressure.

Poor Water Quality

A major indicator that a pressure vacuum breaker isn’t working is if your water quality is poor. For example, if you notice water that is discolored, cloudy, or smelly, it could mean the water is contaminated. If you don’t notice any changes in the appearance or smell of your water, but it tastes different when you drink it, stop drinking it right away and have a pro come to inspect the plumbing.

Winterizing a Vacuum Breaker

Although events that can lead to negative pressure in your water supply are rare, it’s still important to keep the pressure vacuum breaker in good working condition just in case. Aside from general wear and tear, failing to winterize the vacuum breaker is a top cause of failure.

As part of your sprinkler winterizing checklist, you’ll need to drain the sprinkler system and then blow it out with an air compressor. Then, you can open the check and air inlet valves to prevent any damage to the breaker or the rest of the sprinkler system.

When to Replace a Pressure Vacuum Breaker

The interior parts of the pressure vacuum breaker tend to wear out every five to 10 years. You can repair the device by replacing the worn parts as needed. By keeping up with this maintenance, your backflow preventer can last decades.

Pressure vacuum breakers typically need to meet local codes because failure can contaminate your water supply. Be sure to contact a sprinkler repair company to service your vacuum breaker, and schedule inspections about every three years to catch potential problems early.

What to Do When the Vacuum Breaker Fails

If your vacuum breaker fails, hire a local sprinkler repair pro to repair it as soon as possible. A pro can inspect, test, and repair the system, then test it again to make sure it is working properly. These tests need to be completed by a certified pro, who will check that the PSID (pounds per square inch differential) remains steady at 1.0 or higher.

If it falls lower, your pressure breaker may need to be cleaned or repaired, which will cost about $30 to $200 for an expert to handle. If the entire pressure vacuum breaker needs to be replaced, expect to spend about $200 to $600.

- Why Your Vacuum Won't Turn On: 9 Potential Reasons

- 4 Common Vacuum Cleaner Problems and How to Fix Them

- How to Tell If a Breaker Is Tripped: Everything You Need to Know

- 9 Tips to Help Increase the Water Pressure in Your House

- Why the Water Heater Keeps Tripping Breaker

- 7 Tips for Vacuuming Your Stairs to Get Dust-Free Results

- Why Is My Vacuum Not Suctioning? 10 Troubleshooting Tips

- How to Replace a Circuit Breaker: A Complete Guide

- Why My Breaker Switch Won’t Stay On and How to Fix It

- 8 Reasons There Is Low Water Pressure In Your Kitchen Faucet