Get a clear estimate for attic fan repair costs to learn what impacts pricing, how to save, and whether to repair or replace your attic fan.

Keep the juice flowing smoothly with the right wire stripping tools

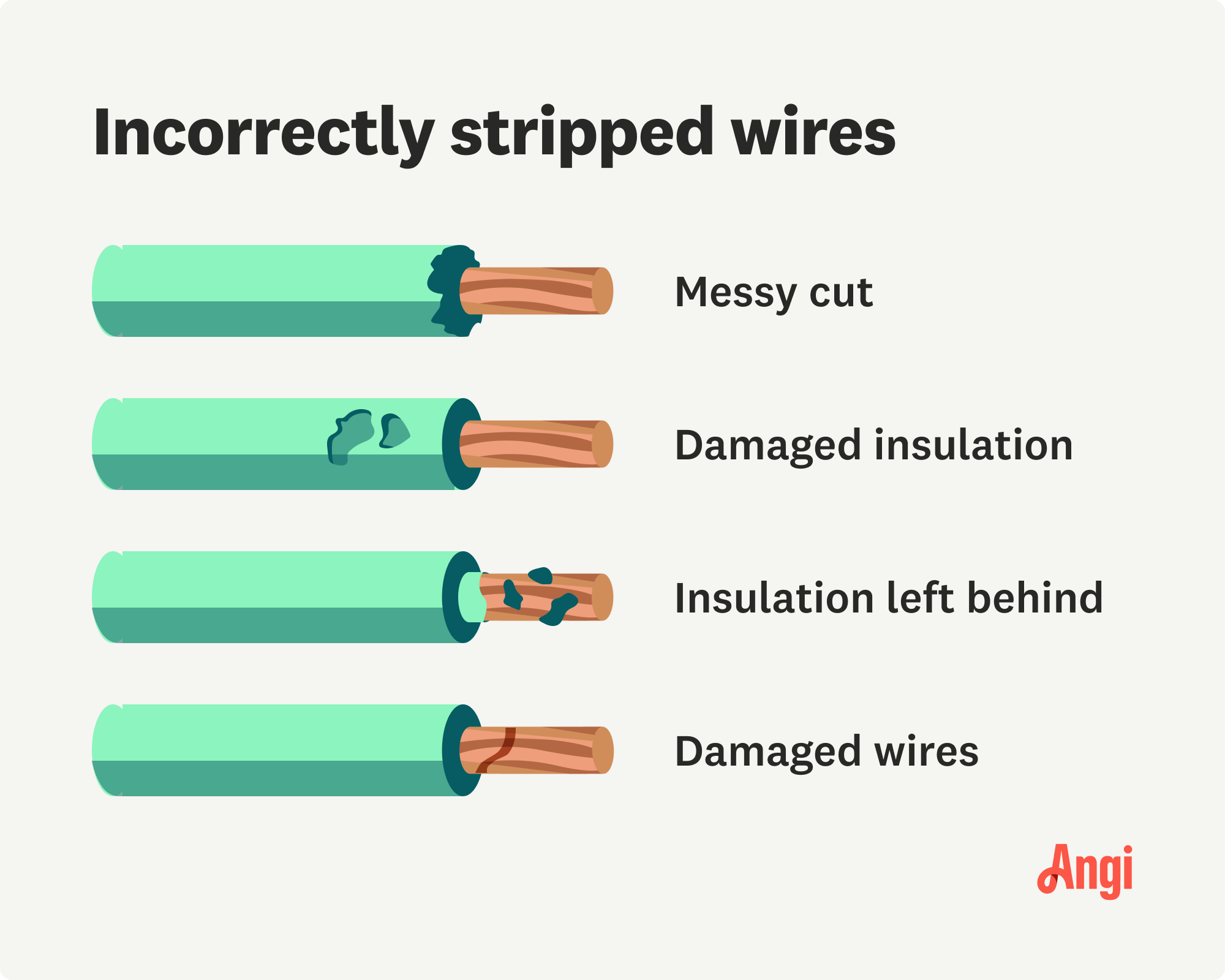

Improper wire stripping can damage the wire, which could lead to faulty connections or short-circuiting.

If you DIY wire stripping without proper training, you increase the risk of shocks or fire.

An electrician can handle wire stripping alongside other electrical work for quick, safe repairs.

Pros know the correct tools to use to avoid nicking or cutting the conductor.

Hiring an electrician near you for any electrical work will guarantee your project meets local building codes.

Learning how to strip a wire properly can make some DIY tasks more manageable, like rewiring a lamp or other appliance. We recommend calling a local electrician to install electrical wiring in your home. Regardless of why you need the plastic coating removed from your wire, you can use a number of different tools and techniques to get that shiny copper wire out in the open.

If you’re stripping wire for electrical purposes—as opposed to stripping it for scrap—it’s important to avoid nicking, scratching, or cutting into the wire(s) inside the plastic coating. Let’s take a look at how to do it.

We don’t recommend doing any electrical work yourself unless you have extensive training and skill. If you have enough know-how and want to attempt some rudimentary wiring, please follow these basic safety tips:

Turn off the electricity to the area you’re working on. Never attempt any electrical work on live wires.

Check the wires with a voltmeter. Even if you think you’ve shut off the correct fuse because it was labeled correctly in the fusebox, it’s better to be safe than sorry and check the connection with a voltage tester.

Do not use equipment with exposed or frayed wires.

Keep the work area dry, and do not let wiring or equipment come into contact with water or wet areas.

Wear non-conductive gloves and eye protection.

Remove conductive items like chains, watches, and other jewelry before doing electrical work.

Assume a wire is live unless you’ve checked it first.

Barricade the work area to keep pets, children, and others out except someone working with you.

Consult a professional electrician if you have questions or need help.

If you’re stripping wires to repair small appliances or motors, it’s important that you don’t damage the metal wire inside the sheathing in the process. Cuts, nicks, and other damage to the wire can cause shorting and faulty connections and weaken the wire, likely shortening its life span.

Average cost: $30

This tool will most likely do the cleanest job without damaging the wire. However, this will also be the most expensive and most complicated option. Using it may also be challenging because of its size and weight; it’s bulky and more awkward to handle than a regular wire stripper/cutter. This tool is used primarily by professional electricians. It’s important to ensure that the tool can handle the size of wire you’re stripping.

For example, some models work on 8-24 AWG solid wire and 10-22 AWG stranded wire. Wire gauges indicate the thickness of the copper wire or combination of wires inside the sheathing. The smaller the number, the thicker the wire and the more amperage it can handle. Following are some of the more common AWG (American Wire Gauge) sizes:

18-gauge

16-gauge

14-gauge

12-gauge

10-gauge

8-gauge

6-gauge

4-gauge

2-gauge

Here are the basic moves with the self-adjusting wire stripper/cutter. As always, follow the manufacturer’s specific directions for the tool.

Set the parameters to match the wire gauge you’re cutting.

Insert the wire and squeeze the handles. The tool should adjust, cut the sheath, and strip the sheath to expose the wire core.

Average cost: $12

A wire stripper looks like a flat pair of pliers with a series of different-sized holes for clipping and cutting the plastic coating on different wire gauges. This tool makes cutting and stripping insulation from wires an easy DIY job. Follow these steps:

Find the hole that matches the gauge of the metal wire you want to strip. Make sure that the hole is smaller than the overall thickness of the wire with the coating on it, but bigger than the wire inside the coating so that you only cut the plastic insulation and not the wire inside.

Determine how much wire you need to expose. Measure and mark the spot with a pen or marker.

Open the wire stripper and place the wire in the correct hole size at the mark (if you made one). Double-check that the wire is in the correct gauge size.

Close the wire stripper on the wire and squeeze to cut the plastic coating. You may hear a small click as the tool cuts the sheathing.

Keep the tool clamped and rotate around the wire to ensure the insulation is cut.

With the tool still clamped, pull along the wire to slide the coating off the wire, exposing the metal inside.

Important note that applies to each method: Make sure to not cut, gouge, or nick the wire itself, as this can keep the wire from functioning properly. If the wire is damaged, clip that section of wire off and start over.

Average cost: $12

This method is a last resort move because of the higher probability of damaging the wires by cutting too deeply. If you don’t have a wire stripper available, a sharp pair of scissors couldwork. You’ll want a heavy-duty pair of scissors rather than the ones kids use in school. This method requires more care as to not cut or damage the metal wire inside while cutting the plastic sheathing.

Place the wire in the open scissors where you want to cut.

If you can, roll the wire to spin it against the blades to score the sheathing slowly. If you can’t roll the wire, rotate the scissors back and forth around the wire to score the plastic coating.

Check the depth of the cut frequently to be sure you don’t cut too deeply.

Once you’ve cut deeply enough, pull the plastic sheathing off to expose the wire.

Average cost: $3 to $5

As with the scissors option, this method is discouraged. We highly recommend getting one of the stripper/cutter tools mentioned above. This process is similar to using scissors, except you only have one blade. Make sure you have a fresh blade, so it’s sharp and cuts more easily into the sheathing.

Rest the wire on a piece of wood or something rigid.

Rest the utility knife blade against the wire where you want to cut it.

Roll the wire between the wood and the blade, slowly pressing harder so the blade cuts into the plastic sheathing.

Check frequently how deeply the blade has cut, making sure you don’t cut too deeply.

When you’ve cut through the sheathing, twist it with your fingers and pull it off the end of the wire.

Stripping wire is a relatively easy job you can do yourself, especially if you’re working on small household appliances or motors. However, if you’re stripping wire for work on the electrical system in your home or apartment, you should contact a local electrician. Most professional electricians charge between $50 and $150 per hour for labor. You can always watch how they strip wire and with what tools. You may be stripping wire for some of the below projects, and if you find you’re already in over your head, it may be easier to hire an electrician.

| Project | Average Cost |

|---|---|

| Replace an electrical outlet | $9–$35 per outlet |

| Ground a two-pronged electrical outlet | $135–$300 per outlet |

| Add a GFCI outlet | $130–$300 per outlet |

From average costs to expert advice, get all the answers you need to get your job done.

Get a clear estimate for attic fan repair costs to learn what impacts pricing, how to save, and whether to repair or replace your attic fan.

Electrical panel replacement costs $530 to $2,100, depending on the location, the type of hardware, and any required building materials.

The cost of a whole-house surge protector depends on the materials, size, installation, and more. This guide will help you budget for a new surge protector.

Planning out a 50-amp circuit? Selecting the right wire size is crucial. Find out how to determine the right 50-amp wire size.

Are there outlets not working in one room in particular? Learn what could be causing the issue and how to solve the problem.

Grounded circuits are happy (and safe) circuits, but what if you live in an older home with pre-grounded receptacles? Here are ways to ground without a wire.