What you’ll pay in Columbus, OH, for furnace repairs depends on many factors. Here’s a breakdown of what can go wrong and the cost to fix those issues.

Wrap up your energy efficiency issues

This project can be costly in more ways than one. Hire a pro to get the job done right the first time, avoid potential injury, and eliminate budget-breaking DIY mistakes.

An efficient HVAC system requires properly sealed and insulated ductwork. If your energy bills are high, your home heats or cools unevenly, or you have other issues like condensation on ducts, wrapping exposed ducts may help. This job varies in cost and complexity based on home size and duct insulation type, but you may be able to do it yourself and save hundreds on labor.

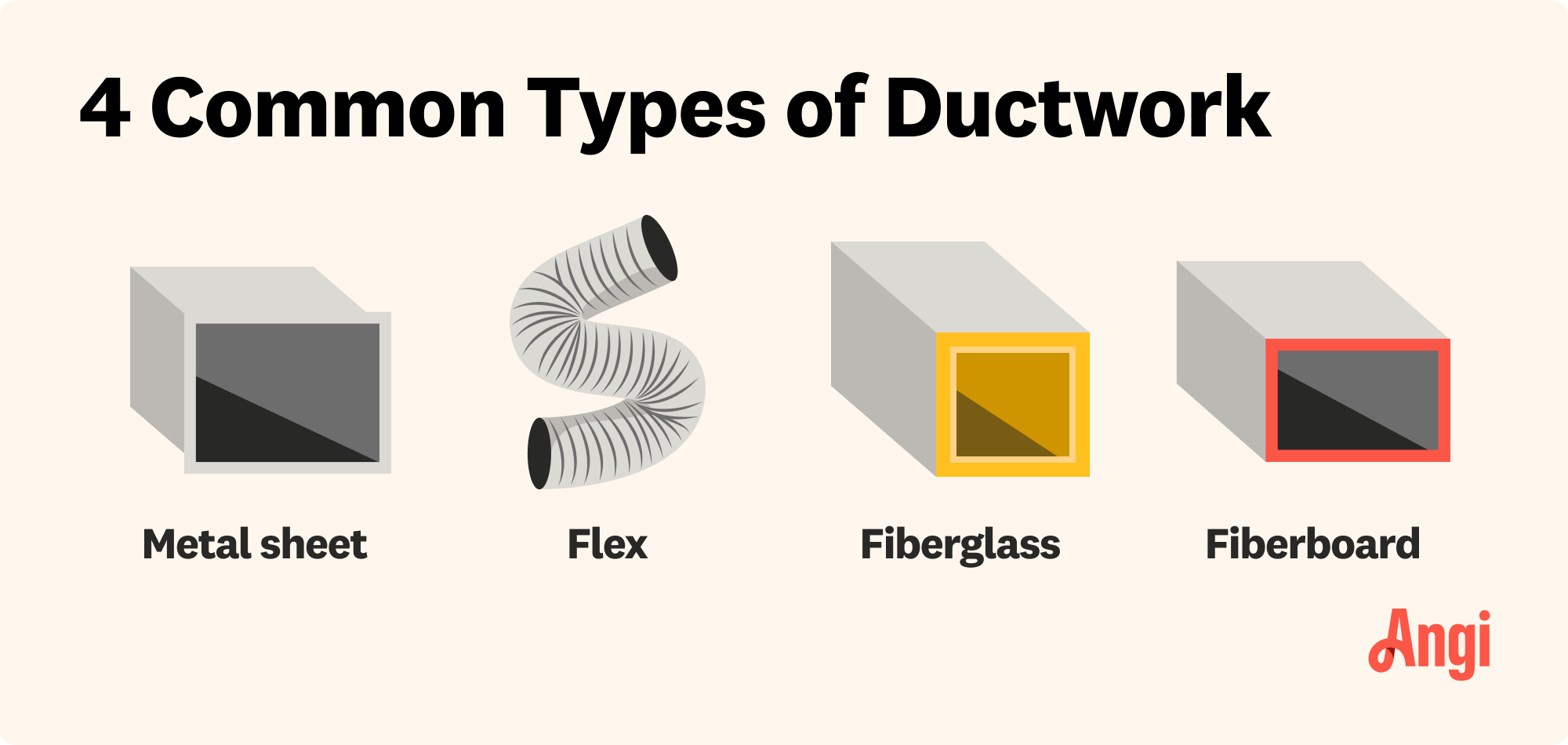

Before you begin, look closely at your ducts to determine what’s needed. Flexible ducts often come pre-insulated and may just need minor sealing. Rigid ducts will require precise cutting and fitting. Ducts in attics, crawl spaces, and other unconditioned areas should have an additional vapor barrier included in the insulation.

If you have internal ductwork that runs through walls, you'll want to hire an HVAC specialist to access and insulate it properly.

Before you get started, turn off the power to your HVAC unit. You should also dress appropriately. Whenever you work with fiberglass insulation, wear long sleeves, pants and socks that cover your legs, safety goggles, sturdy work gloves, and a respirator breathing mask.

Before insulating, wipe the exterior of your ducts with a clean, dry cloth so they're free from dust. This will allow the tape and mastic to adhere properly. If any of your ducts have existing insulation, assess it for wear. If it's old and damaged, you'll want to remove and replace it.

Some insulation can be removed by peeling off the tape that’s holding it to the duct. Otherwise, you'll need to cut it away with your utility knife carefully. Be extremely careful with a knife around flexible or semi-rigid ducts, as these are prone to tears. Put the old insulation into sealed garbage bags and dispose of or recycle it per your local waste collection guidelines.

Once your ducts are clean and bare, turn the system back on and visually inspect the ducts for kinks or cracks. You can also detect leaks by holding a smoke pen or lit incense stick beside the ducts. Leaking air will disturb the smoke.

Turn off the system's power again, and seal any leaks by applying mastic duct sealant with a paintbrush. Allow the sealant to dry thoroughly before proceeding to the next step.

Use your tape measure to determine the circumference of your ducts. Then, use your measuring square and utility knife to cut your insulation to that width plus an additional two inches for overlap. You'll need to cut many sections to cover the entire duct.

Wrap the insulation around the duct, overlapping and securing the seam with foil tape. The insulation should fit snugly without being compressed. Pinch the seam tightly and secure it with short pieces of foil tape. Seal the ends of each length of insulation to the duct or the next length. Repeat this process until your ducts are sealed entirely.

For lengths of ductwork that are difficult to access on all sides, use preformed insulation in a size that matches the diameter of your ducts. To install preformed insulation, you’ll need to measure and cut the insulation tubes and then remove fittings to slide them over the duct. Replace any removed fittings and use mastic to seal their joints. Seal any remaining edges with foil tape.

As you insulate your HVAC ducts, be aware of these common DIY mistakes to avoid:

Not overlapping seams sufficiently: As you wrap ducts with insulation, all seams should overlap by about two inches to prevent gaps.

Ignoring existing damage: Address holes, compressed insulation, and unsealed leaks before wrapping your ducts. Otherwise, they’ll be much harder to detect.

Compressing insulation: Compression reduces insulation R-value and effectiveness.

Ductwork insulation can be done any time of year. However, you'll likely want to handle it during the spring or fall when you're least likely to need to operate your HVAC system regularly.

Professional ductwork insulation costs $2,500 on average. You could save on labor by doing the job yourself, but it can be very time-consuming with high material costs, making mistakes pricey.

Ductwork is also often hard to access, and sections may need to be removed and reattached to complete the task. Some municipalities require an HVAC license to perform duct insulation.

If you lack the time or experience necessary for the job, contact a local insulation company. You can trust these trained pros to safely and properly handle the job for you.

From average costs to expert advice, get all the answers you need to get your job done.

What you’ll pay in Columbus, OH, for furnace repairs depends on many factors. Here’s a breakdown of what can go wrong and the cost to fix those issues.

When your heat goes out, it can cause a bit of a panic. But knowledge is power, so let's go over radiator repair costs before that happens.

Getting AC and furnace replacement done at the same time can lead to huge benefits for your wallet and your home. Here’s everything you need to know.

If your furnace is making loud noises, it could be the first sign something is failing. This guide will go over some of your furnace’s most noisy issues.

Discover the benefits of a DIY outdoor wood furnace forced-air system. Cut costs, reduce fire risk, and embrace renewable heat for your home.

A HEPA filter can help clear airborne particles that plague your home, such as dust and pollen, making the air cleaner and easier to breathe.