How to Install Crown Molding: 6 Detailed Steps

A simple way to give your room a regal feel

- Stud finder

- Angled paint brush or paint sprayer (optional)

- Brad nailer

- Caulk gun

- Ladder

- Pencil

- Painter’s tape

- Crown molding

- Paint or stain (optional)

- 2 ½” nails

Elevate your interior’s aesthetic by installing crown molding where the wall and ceiling meet in the room. This type of trim adds elegance and a polished finish. While cutting the crown molding requires more carpentry skill and attention to detail, installing the cut boards is a straightforward project. Use this guide to learn how to install crown molding and give your room that wow factor.

Preparing to Install Crown Molding

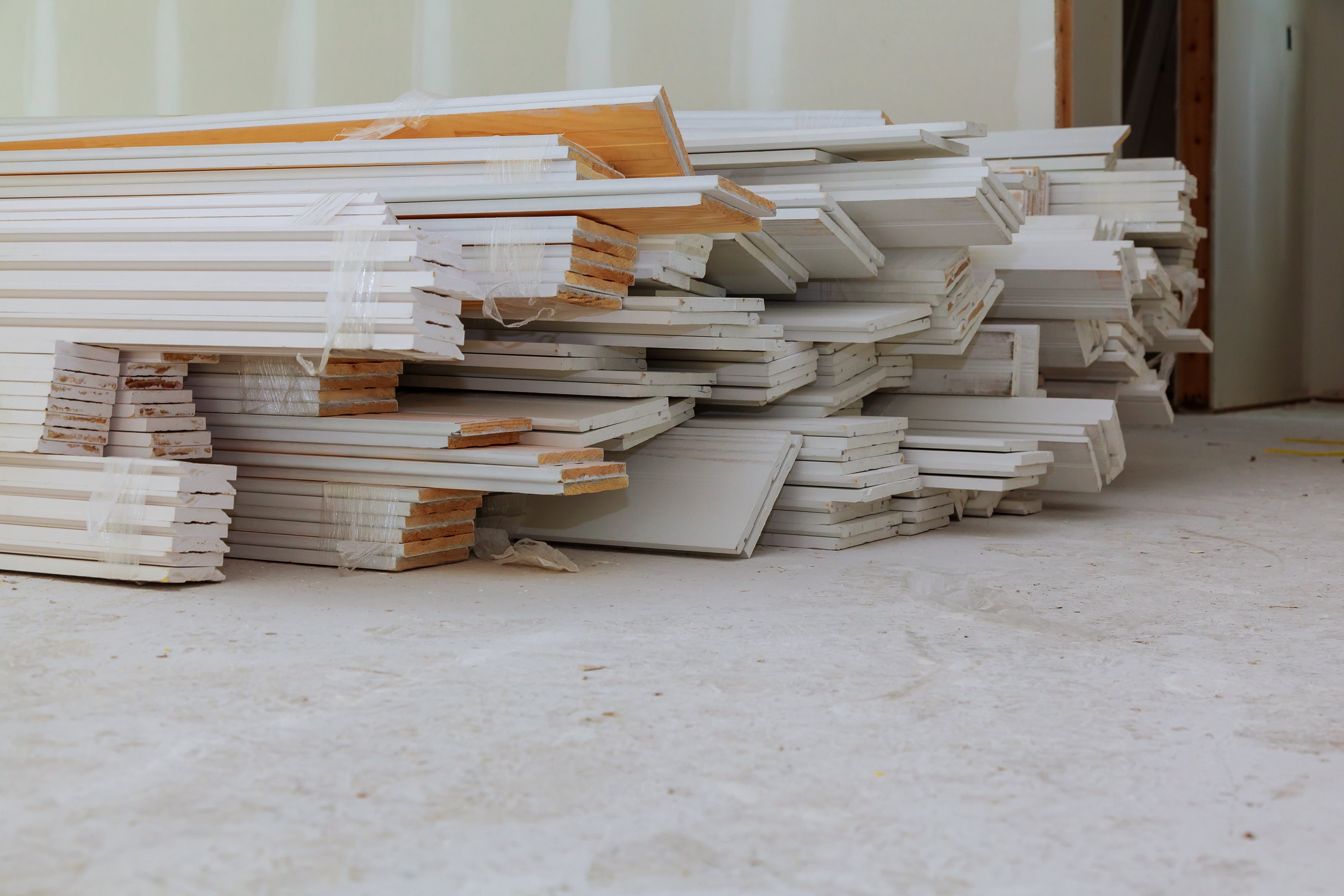

Before you start tackling this project, move all the furniture to the center of the room so you have space to work and can avoid damage to any items. Next, remove any old crown molding boards using a pry bar with a scrap piece of wood behind it to protect the wall from damage.

After the old crown molding is removed, bring the new boards inside for at least 24 to 48 hours so they can acclimate to their new environment. And lastly, dust the ceiling to remove any cobwebs or debris.

Measure the Room

Photo: JodiJacobson / Getty Images

Photo: JodiJacobson / Getty ImagesUsing a tape measure, measure the walls from corner to corner to determine how much molding to buy. Remember to purchase an additional 10% of materials to allow for waste and potential inaccuracies when cutting.

When measuring the wall, start from where the bottom edge of the crown molding will sit. For example, start 3 inches below the ceiling for trim that is 3 inches wide.

Measure and mark the studs with painter’s tape using a stud finder.

Transfer these measurements to the boards, marking the bottom of the crown molding with a pencil. Be sure to show the angle where the boards meet in the corner for accuracy when cutting.

Pro tip: It’s helpful to make a sketch of the room to serve as a blueprint to show the measurements of each wall, alcove, and bump out. This will help you better visualize the room when you’re looking for materials at the home improvement store.

Measure and Cut the Boards

Photo: ungvar / Adobe Stock

Photo: ungvar / Adobe StockUsing your measurements as a guide, it’s time to cut the crown molding. There are different techniques you can use when cutting the boards, depending on the layout of the room. For a more in-depth description of this step, you can refer to our guide on how to cut crown molding, but here are some of the basics:

Scarf Joint: A scarf joint is used when one piece of crown molding is shorter than the length of the wall to connect to a new piece. The pieces are cut at opposing 45-degree angles so they overlap, creating a seamless transition.

Inside Corner Cut: For 90-degree corners and alcoves in the room, make an inside corner cut. For this type of cut, the left side will angle up to the left and the right side angles up to the right so that the top edge of the board is longer than the bottom edge. Set your miter saw to a 45-degree angle and flip the board upside down. Swivel the saw to match the direction and angle of the mark and cut the board.

Outside Corner Cut: If you have any bump outs in the room, you will make an outside corner cut. An outside corner cut is the opposite of an inside corner cut, as the left side will angle to the right and the right side will angle to the left, so the bottom edge is shorter than the top edge. Turn the board upside down and set the miter saw at a 45-degree angle in line with your pencil mark to make the cut.

Coped Joint: When cutting inside joints, curved shapes, intricacies in the molding, and imperfections in the ceiling and wall can cause the trim to not align properly. In this instance, you can create a coped joint, so the boards fit flush against one another. Remember, this technique requires more carpentry skill and a specific coping saw.

Paint Or Stain the Boards (Optional)

Photo: NoSystem images / Getty Images

Photo: NoSystem images / Getty ImagesDepending on the boards you buy, they may need to be painted or stained, and it’s best to do this step after cutting but before nailing them into the wall. For example, MDF often comes pre-primed, but you may want to add another coat of paint to fill in any bare spots, paint a color other than white, or add a glossy finish to the board.

If you purchased bare wood boards, you may choose to stain or paint over them before installing them. You can either paint them using an angled paintbrush or a paint gun, depending on your preference.

Painting the boards with a paint sprayer

For the experienced DIYer, a paint sprayer can be used to complete this step more quickly, making this a good choice when working with a large amount of material. It also works well for boards that have intricate details since it helps the paint cover even the smallest of crevices that a brush may not reach.

In a well-ventilated room, wearing the proper protective equipment (such as a respirator), lay the boards out and fill the spray gun’s reservoir. Evenly apply the paint in the same direction, wiping away any drips or splatters from the boards with a spare paintbrush. Allow the boards to completely dry, then apply a second coat.

Painting the boards with an angled paintbrush

An angled paintbrush works well for beginners since getting an even coat with a sprayer can be a challenge. Dip a high-quality brush into the paint can and wipe off the excess paint on the edge. Apply the paint in an even coat along the board, working with the grain of the wood. Allow the paint to fully dry, then apply a second coat.

Test and Trim the Boards

Before you start attaching the pieces to the wall, you should double-check the fit. In addition to testing the right length of each piece up against the wall, make sure each of the pieces fits together properly. If they don’t fit and you need to remove wood from the back of the piece, you can use a sanding drum and drill. If the piece is too long, use the miter saw to cut the square-cut end.

Attach to the Wall

Photo: Brett Taylor / Getty Images

Photo: Brett Taylor / Getty ImagesOnce you have cut each piece and the paint has fully dried, you can attach the crown molding to the wall. Start with the inside corner of the long wall in the room. Using the stud marks on the wall for reference, hold the piece in place with the corner and nail into the wall using your brad nailer and 2 ½ inch finishing nails. Continue in the same direction throughout the room, attaching the pieces to the wall so they fit snugly with the preceding board.

Pro tip: It is recommended to use a nail gun for this step, but if you don’t have one, you can hammer the boards into the wall (however, you will need to pre-drill the holes to avoid splitting the boards).

Make the Finishing Touches

Photo: Vadym Plysiuk / Getty Images

Photo: Vadym Plysiuk / Getty ImagesFill in the nail holes with a paintable caulk.

Use a caulk gun to seal the top and bottom edge of the molding, fill in any gaps in the corners or scarf joints, and fill in nail holes. Wipe away excess caulk with a rag or your fingertip for a smooth finish.

Inspect the boards and apply touchup paint over nail holes or fill in any visible bare spots.

Installing Crown Molding Yourself vs. Hiring a Pro

While installing crown molding is certainly a doable project for an intermediate DIYer, it can be a time-consuming task—especially if you’re adding molding to a large room or several rooms in the house. The biggest obstacle homeowners run into is cutting the pieces to the correct size. It’s best to cut each piece slightly longer and then shave them down until you have a perfect fit. But doing so will add extra time to the project.

In terms of cost, if you already have a miter saw and nail gun, you’ll just need to factor in the price of materials. If you choose a local crown molding company, prices can range from $610 to $2,110, with an average cost of $1,292. If you’re looking for a specific style of molding, want a custom finish, or need to repair molding in a historic home, relying on a pro is probably the best choice.

- Power Washing

- Greenhouse Companies

- Wood & Pellet Stove Repair

- Vinyl Siding Repair Contractors

- TV Antenna Services

- Ceiling Repair Companies

- Wall Repair Services

- Emergency Handymen

- Countertop Repair

- Vinyl Siding Cleaning

- Furniture Assembly

- Trampoline Assembly

- Carport Repair

- TV Mounting

- Chain Link Fence Repair

- Picture Hangers

- Electrical Handymen

- Handymen Plumbers

- Mailbox Installation

- Treehouse Builders

- Door Refinishing

- Aquarium Services

- Grab Bar Installation

- Caulking Services

- Grill Assembly