Find composite fencing costs based on fence type, labor, and more in this guide. You can expect your project to cost $11 to $45 per linear foot.

Building a seawall costs $25,000 on average, with a wide range between $10,000 and $100,000, depending on the size and type of seawall.

Building a 100-linear-foot seawall starts around $15,000, while a 700-linear-foot seawall costs at least $105,000.

Labor costs range from $40 to $100 per hour, but can increase to $300 per hour if the project requires heavy equipment.

Wood seawalls are one of the cheapest options, starting at $150 per linear foot, while concrete, steel, and vinyl all cost at least $200 per linear foot.

Replacing a seawall costs 80% more than repairing it.

Have you ever dreamed of living on the coast and wondered: how much does it cost to build a seawall? With an average cost of $25,000 and a range from $15,000 to $60,000, seawalls are an expensive but often necessary project for houses on the water. Expect to pay $100 to $800 per linear foot, with more complex projects sometimes reaching $2,000 per linear foot—or more.

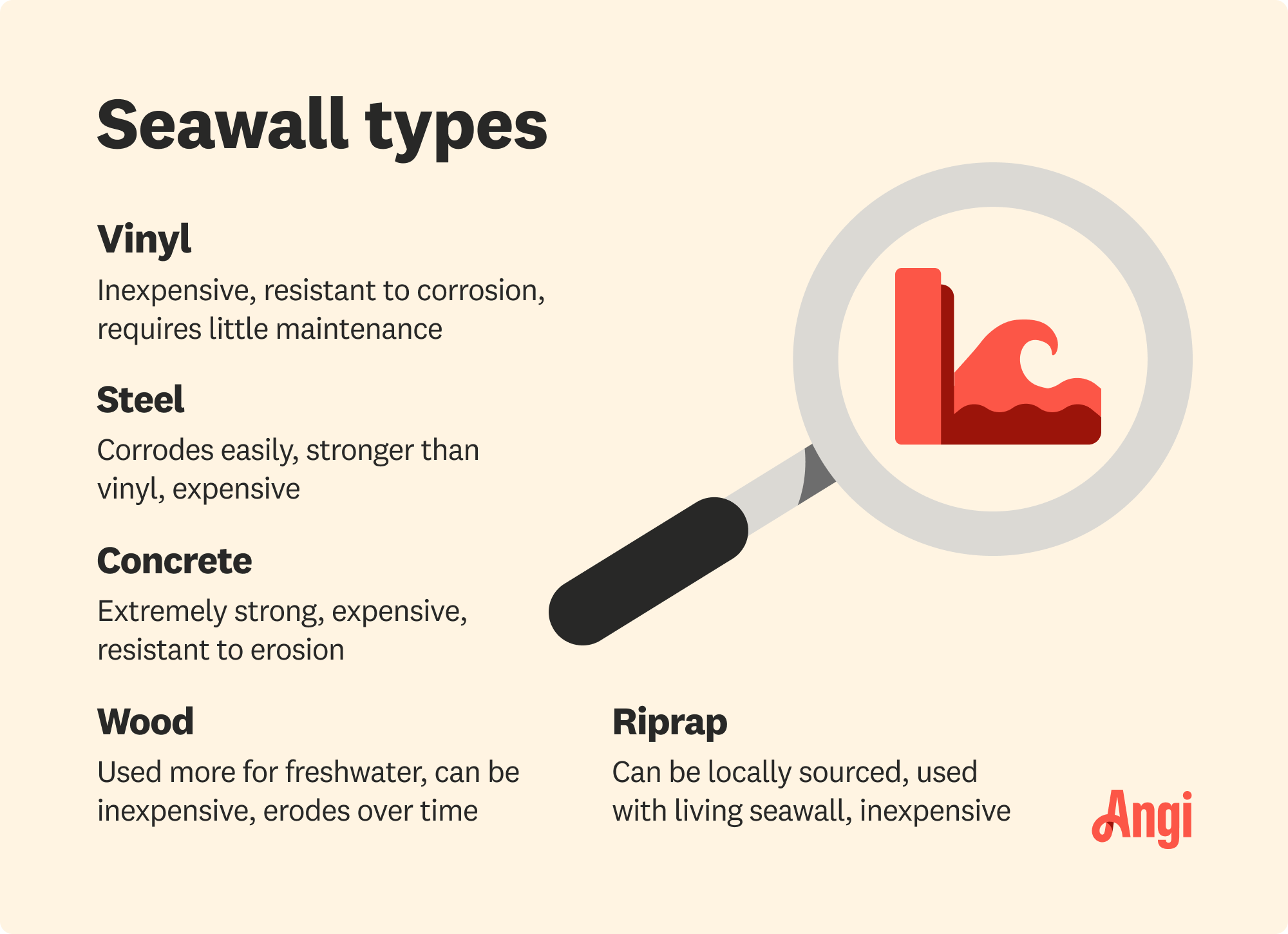

Homeowners who need a seawall quickly discover this is a project where professional input is a must. The type of seawall you build is more determined by the soil type and water characteristics where the seawall would be installed, so in many ways, you don't have a ton of options when it comes to material.

| Seawall type | Cost per linear foot |

|---|---|

| Vinyl | $200–$600 |

| Steel | $250–$700 |

| Concrete | $200–$800 |

| Wood | $150–$500 |

| Riprap | $70–$400 |

Because seawalls are often priced in linear feet, the size of the wall is one of the largest factors in the total price. The thing about seawalls is they're rarely built in a portion of the property, but rather encircling the entire yard or at least the side that's up against the body of water.

It's not only linear feet that factor in either, but the height of the wall as well. A seawall can be anything from four or five feet high to 15, 20, or more. This depends on your soil type and how deep the water is adjacent to your property, as well as the level of access the crews have when building the seawall.

| Seawall Size in Linear Feet | Cost for Wooden Seawall | Cost for Concrete Seawall |

|---|---|---|

| 100 | $15,000–$50,000 | $20,000–$80,000 |

| 150 | $22,500–$75,000 | $30,000–$120,000 |

| 225 | $33,750–$112,500 | $45,000–$160,000 |

| 300 | $45,000–$150,000 | $60,000–$240,000 |

| 700 | $105,000–$350,000 | $140,000–$560,000 |

Calculating the cost of a seawall contractor can be challenging; for larger jobs like this, you’re typically quoted a single amount, which includes all materials, labor from various contractors and engineers, and equipment. In general, expect labor to cost between $40 and $100 an hour, but up to $300 an hour if the project requires the operation of heavy equipment, such as bulldozers and cranes.

Building a seawall isn’t a job for your average DIYer. Make sure the professional you hire is a licensed building contractor—ideally, with a marine contractor’s license. You’ll also need to contact a local structural engineer or team of engineers to assess the site and design the wall before work can begin.

Where you live greatly impacts the cost of building a seawall. Local codes may dictate different depths for seawalls in different locations, and the cost of materials and labor varies across different regions as well.

In general, saltwater seawalls cost twice as much as freshwater seawalls. That’s because:

Saltwater seawalls require more durable (and more expensive) materials that can withstand saltwater corrosion.

Tidal changes in the ocean mean you may need to build your seawall taller.

Permits for ocean seawalls are generally more complicated (and more expensive) than they are for lake seawalls.

Building a seawall requires a lot more preparation than even some large construction projects. If a seawall fails, its soil can drain into the water and destroy the foundation of a house close to the wall. It's also possible that the water rises beyond the seawall and causes water damage directly.

Some of the costs associated with that prep work include a site survey, permits, an environmental impact assessment, and design work by a structural engineer.

As part of the site survey, your team of engineers and marine contractors will analyze the type of soil and its density. They’ll also monitor high and low tide levels over at least a month and measure the distance between the property and the proposed location of the seawall.

This will be baked into the overall cost of building a seawall, but expect to be charged if you have the survey conducted but don’t move forward with the project or that contractor. Though this can vary significantly, a typical land survey costs between $800 and $5,500; a site survey for a seawall is much different from a traditional land survey, but this is a good frame of reference.

Like any large project, building a seawall must be approved by your local government. Seawall permits are complex so this should be done with a professional. There will likely be several inspections before your municipality approves the permit. This legal permission from the city will cost between $150 and $2,500.

Building a seawall can have negative effects on the coastal area where it’s constructed, including the elimination of tidal habitats and increased erosion of other beach areas. You’ll need to get an environmental impact assessment. These can cost anywhere from $2,000 to $15,000—or even more for larger, commercial projects.

Designing a seawall requires a very specific type of knowledge. You’ll need to hire structural engineers who understand soil mechanics and conditions to design an effective seawall. Engineering firms will vary in what they charge for this service, but don’t expect it to be cheap—and don’t have someone without this background design your seawall instead.

If there's one important point to drive home here, it's this— don't build a seawall yourself. The amount of money that you would spend on materials would still be quite high. Unless you have experience in land surveying and large-scale construction, you'll probably end up spending more trying to DIY this project and hiring a local fencing professional to fix it than you would have if you had just hired the professional in the first place.

Building a seawall isn't an easy DIY project; it takes serious investment and expertise. It also requires specialized equipment, which will cost you a large amount to rent but would be included in a professional's quote. Unless you have experience with these types of projects, you likely won't get past the permit stage.

Replacing an existing seawall is even more challenging—and more expensive—than installing a new one. That’s because you’ll need a structural engineer with a marine background to assess the damage before a marine contractor can carefully remove the old seawall and install the new support structures for the replacement seawall.

Whenever possible, repair an existing seawall instead of replacing it. Repairing a seawall can also be costly, but unless the damage is extensive and hardly salvageable, it is worth it to repair instead of replace. In general, replacing a seawall costs 80% more than repairing it.

Building a seawall is an expensive process, and while there are some projects where you can cut corners, this isn't one of them. Even for smaller seawalls, there are extreme forces to consider so that the walls are built within the safety and structural parameters an engineer designs.

You could save money if you have clearance to build a wooden seawall and want to use reclaimed materials or if you have the option to choose materials, you could go with something less expensive like vinyl. Seawall construction is complicated but you might be able to save some money if you hire a contractor during a slower period of the year or when they have a gap in their calendar.

Home is the most important place on earth, which is why Angi has helped more than 150 million homeowners transform their houses into homes they adore. To help homeowners with their next project, Angi provides readers with the most accurate cost data and upholds strict editorial standards. We extensively research project costs to develop the pricing data you see, so you can make the best decisions for you and your home. We rely on reputable sources, including the U.S. Bureau of Labor Statistics, academic journals, market studies, and interviews with industry experts—all to ensure our prices reflect real-world projects.

Want to help us improve our cost data? Send us a recent project quote to [email protected]. Quotes and personal information will not be shared publicly.

From average costs to expert advice, get all the answers you need to get your job done.

Find composite fencing costs based on fence type, labor, and more in this guide. You can expect your project to cost $11 to $45 per linear foot.

Black fencing adds some elegance to your property while maintaining security. Use this black chain-link fence cost guide to get an estimate for your fencing.

Fence repair costs depend on the extent of damage, your fence's material, and how much of the fence you need to fix. Explore all the price factors in this guide.

Did you know you can extend the height of your fence for more privacy? Read on to learn how to make a fence taller.

Get the facts on the cost of invisible fence repair, including average prices, key cost factors, and tips to save. Learn what impacts your repair estimate and how to budget.

Explore 5 common types of chain-link fences: galvanized, vinyl-coated, privacy, mini-mesh, and security. Find the perfect fit for your property needs.