How to Choose the Right Home Gas Pipe Size

Finding the right fit isn’t just a pipe dream

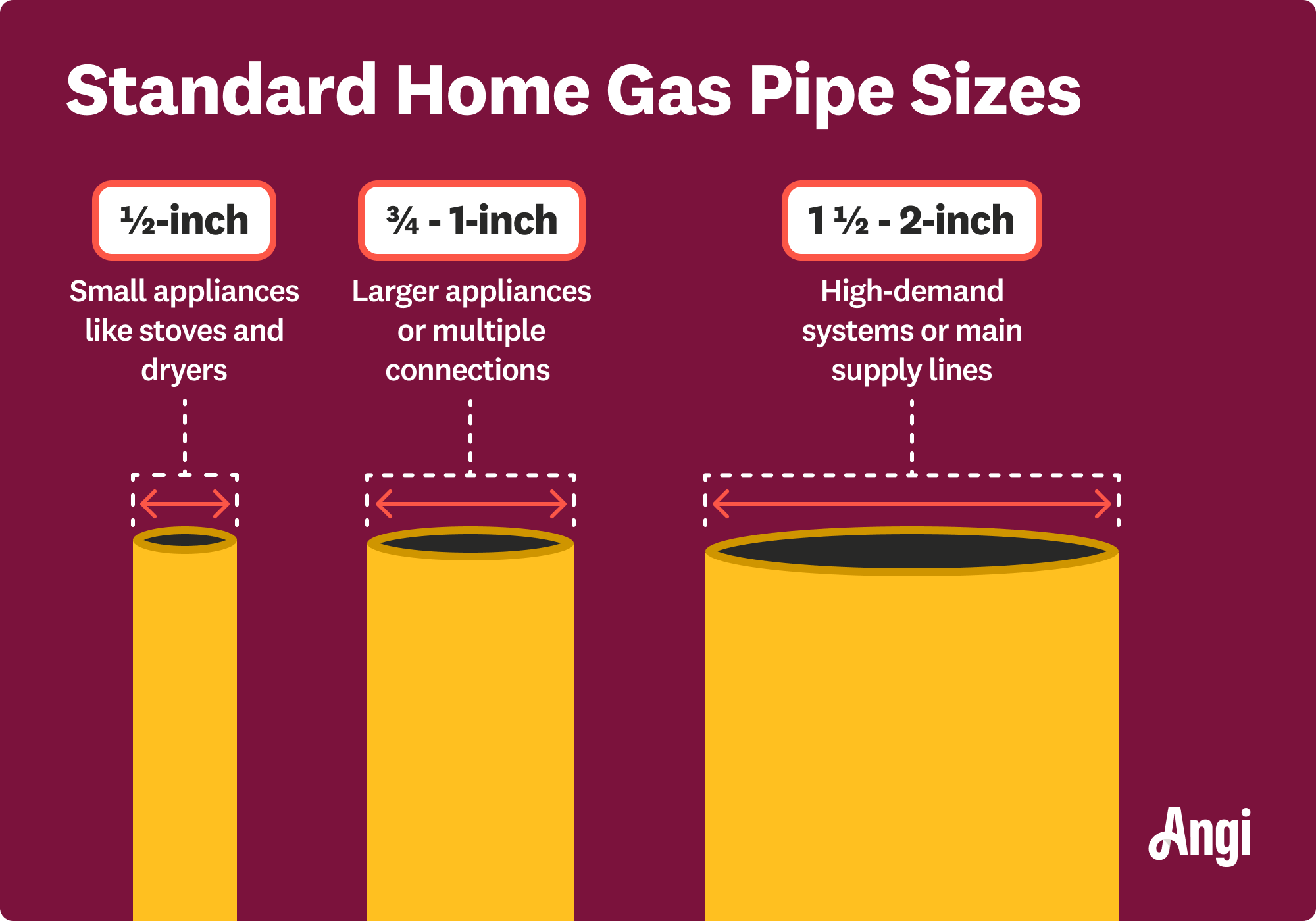

Common home gas pipe sizes range from ½ to 2 inches.

Gas pipe size depends on the type of gas, number and size of appliances, type of gas lines, and layout.

Types of gas pipes include black pipe, corrugated stainless steel tubing (CSST), copper, polyethylene, galvanized steel, and aluminum-plastic composite.

To measure home gas pipes, know your appliance BTU ratings, measure the pipe length, and use a gas pipe size chart.

Always hire a licensed gas plumber for gas line installation and repairs.

The right home gas pipe size keeps your home appliances running safely and efficiently. Choose gas pipes that are too small, and your system won’t have enough pressure to work properly. Go too big, and you’ll pay for more pipe than you need. Since gas pipe sizing depends on factors like appliance demand, pipe length, and pipe material, it’s important to calculate the correct size before your installation. This guide discusses standard gas pipe sizes, how to measure, and what to do if you have the wrong size.

What Is the Standard Home Gas Pipe Size?

There’s no universal gas pipe size because the right size depends on the type of gas (natural gas or propane), the number of home appliances that use gas, and the length and layout of the gas lines. However, the most common residential gas line sizes range from ½ to 2 inches in diameter.

As with any gas-related installation or service, it’s safest to hire a natural gas plumber near you to find the correct gas pipe size and do the actual work.

A professional should always do gas hookups because of the serious dangers and risks involved. Signs you might need gas plumbing repairs are rust, damaged connections, or a gas smell. If you smell gas, turn off your appliance immediately and call a professional to inspect it.

Gas Pipe Size by Type

Gas pipe sizes vary based on the material of the pipe, gas type, and appliance demand. Here are some of the most common sizes for different types of gas pipes:

| Type of Gas Pipe | Common Sizes (Inches in Diameter) | Best Use |

|---|---|---|

| Black pipe | 0.5–2 | Main supply lines and appliances |

| Corrugated stainless steel tubing (CSST) | 0.375–1.25 | Flexible piping for homes |

| Copper | 0.25–1 | Propane applications |

| Polyethylene | 0.5–2 | Underground gas lines |

Black Iron Pipe

Black iron pipe is the most common material for home gas lines. It is durable and resistant to leaks. Standard sizes range from ½ to 2 inches, depending on the gas flow needs.

Corrugated Stainless Steel Tubing

Corrugated stainless steel tubing (CSST) is a flexible alternative to black iron pipes. It comes in sizes from ⅜ to 1 ¼ inches. Its flexibility makes it easier to install in tight spaces.

Copper Pipe

Copper pipe is used for propane gas lines, but it is not permitted for natural gas in many areas due to corrosion risks. It comes in sizes from ¼ to 1 inch.

Polyethylene

Polyethylene pipes are often used for underground gas lines. Depending on the installation requirements, they are available in sizes from ½ to 2 inches.

How to Measure the Right Gas Pipe Size

Here’s how to determine the correct gas pipe size for your home:

Identify the appliance BTU ratings: Check the manufacturer’s specifications for each gas-powered appliance in your home.

Measure the pipe length: Longer runs of pipe require larger pipes to maintain the correct pressure. To size a gas line correctly, use the longest-length method: measure from the gas meter to the appliance that’s farthest from the source, then calculate pipe size based on that distance. A pro can help you ensure you have the right calculations.

Consider the pipe material: Different materials have different levels of durability, flexibility, and corrosion resistance, which determine how much gas can flow through the pipes.

Use a gas pipe sizing chart: When it comes to how to measure pipe sizes, using a pipe sizing chart is the easiest method. Charts combine BTUs, pipe length, and material to determine the right diameter for each pipe.

Think about future expansions: Size pipes accordingly if you plan to add or upgrade appliances in the future.

Pro Tip: Homeowners can measure and estimate pipe sizes, but it’s important to hire a licensed plumber or technician who installs gas lines to confirm the final pipe size.

Factors That Influence Home Gas Pipe Sizes

Gas pipe sizes depend on a combination of several factors that impact efficiency, safety, and compliance with local codes. Let’s look at what you need to know.

Appliance Demand

The more gas-powered appliances you have connected to your home gas line and the more gas they each require, the larger the gas pipe needs to be to maintain proper flow. If the pipe is too small, your appliances may not get enough gas, which can make them underperform and pose safety risks.

Since gas appliance performance varies, check your manufacturer’s specifications or use BTU requirements to calculate the right gas pipe size (see the following average ranges).

| Gas Appliance | Average BTU Requirements |

|---|---|

| Stove | 5,000–20,000 per burner |

| Dryer | 20,000–30,000 |

| Water heater | 30,000–50,000 |

| Furnace | 80,000–200,000 |

Pipe Length and Layout

Gas pressure drops as the gas travels through a pipe. The farther an appliance is from the main gas supply, the larger the pipe needs to be to maintain the right pressure. Shorter runs may allow for smaller pipe sizes, but longer runs require larger-diameter pipes to compensate for pressure loss. Elbows, bends, and tees in piping systems also add resistance and will require pipe sizing adjustments.

Gas Type

Natural gas pipes are larger than propane gas pipes because natural gas has a lower energy density, so natural gas systems need larger pipes to maintain the correct pressure.

Gas Pressure

Most homes have low-pressure gas systems. However, some homes, like those with high-demand appliances, may have medium-pressure systems. The higher pressure may allow for smaller pipes but also requires a regulator to slightly lower pressure before the gas enters appliances. A gas pressure test checks your gas line’s condition and helps diagnose issues.

Pipe Material

The material of the gas pipe affects its capacity. For example, black iron pipe is the most common material for natural gas lines because it is durable, but it requires larger diameters than other types of piping.

CSST is flexible and easier to install but has different sizing requirements than metal pipes because of its ridged interior and wall strength. Your gas plumber can help you determine which pipe material is best for your specific project.

Local Building Codes

Municipalities have specific gas pipe sizing rules based on climate, altitude, and safety concerns. Always check with local building authorities and a licensed plumber to ensure your gas pipe system is in compliance.

What to Do If You Have the Wrong Size Gas Pipe

Incorrectly sized gas pipes can cause major problems, from inefficient appliance performance to gas leaks. If you suspect your gas pipes are too small or too large, here’s what to do:

Identify the Problem

Signs that your gas pipes are the wrong size can include the following:

Appliances failing to heat properly or shutting off unexpectedly

Hissing sounds from pipes

Inconsistent flames on gas burners

Unusual or unexplained gas odors or pressure fluctuations

Consult a Licensed Gas Plumber

Gas systems should never be a DIY project unless you’re trained and licensed. Instead, hire a pro to inspect your gas line size and pressure, calculate the correct pipe size, and recommend upgrades if needed.

Upgrade or Replace the Pipe

If the pipe is too small, you may need to install larger pipes to handle demand, put in a secondary gas line, or upgrade to a higher-pressure system. If your gas pipe is too large, it’s usually not a safety hazard, but it can be inefficient.

While you’ll need to be prepared to spend the average gas line repair and installation cost to replace it—about $120 to $1,400—having correctly sized pipes can save you money over time.

Consider a Gas Line Extension or Reconfiguration

If you’re adding new appliances, you may need to adjust your existing gas line. A pro can reroute lines, add branches, or install regulators to balance pressure across multiple appliances.

Check for Permits and Inspections

Most gas line modifications require a permit and inspection to guarantee safety and code compliance. Your plumber or local building department can guide you through the process.