Concrete driveways stand up to a lot of pressure over the years. How much do concrete driveway repairs cost when it's time to give it a little TLC?

The wrong concrete consistency can put your project in a slump

Concrete slump indicates the workability and moisture levels of a concrete mixture.

Obtaining the right slump is key to building a stable structure.

You or your contractor should test a batch of concrete for slump consistency.

An incorrect slump can cause the structure to set incorrectly or become damaged down the line.

“Concrete slump” might sound like something you want to avoid, but it’s a crucial measurement when pouring concrete. Slump describes the water content and consistency of concrete and is measured by how much the mix slumps down when formed. Learn about concrete slump to ensure you have the right consistency for your concrete project and avoid problems in the future.

Concrete slump measures the amount of moisture in a concrete mixture, which measures its workability and how it flows (or doesn't flow) through a space.

Imagine you're a kid again and working with sand for your sandcastle. The more water you add to the sand, the more it spreads out when you remove the form. Mixing concrete incorrectly is sort of like that.

When working with concrete, slump measurements are important for a few reasons, including successful concrete stability. If the slump is too low, the concrete may not form in the space, leave air pockets, and threaten the integrity of the structure. If the slump is too high, you may experience concrete segregation, the concrete may shrink as it sets, or it may crack or dry inconsistently, meaning you may have to figure out how to sand concrete after it's set.

Contractors also use a slump test to ensure that a large mixture has a consistent slump from batch to batch. A concrete slump test ensures uniformity across the project.

When you're learning how to make concrete or receiving a delivery at a worksite, the specific mixture and your project specifications should list the ideal slump class for both workability and stability. You will need to mix in more or less water to achieve the ideal slump.

If you have premixed concrete delivered, they should clarify the slump class and whether it's been tested. Keep in mind that if the slump is very high, you may need to add reinforcement mixtures—often known as superplasticizers—to strengthen the mix when it sets.

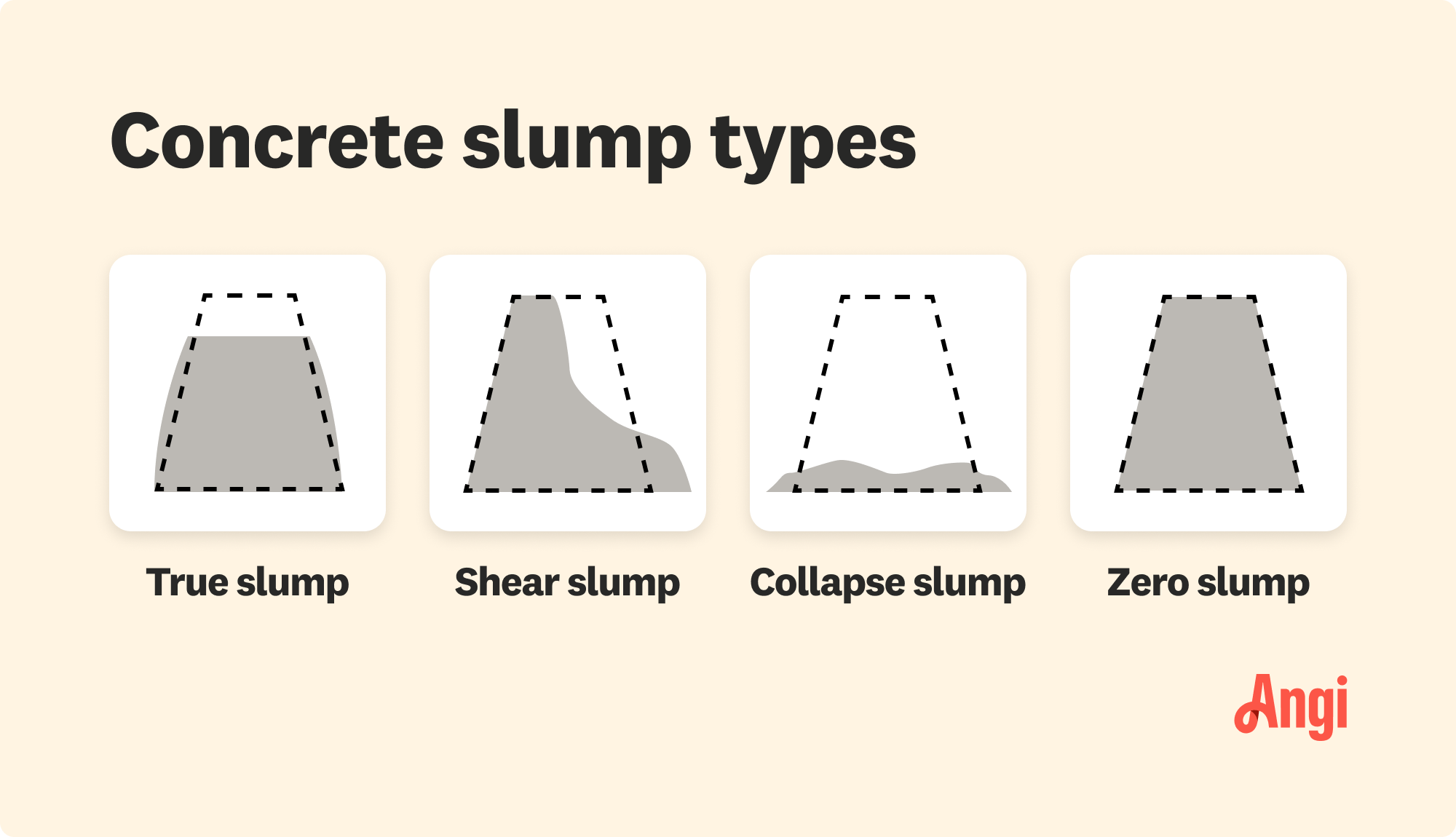

Slump type can be determined with a slump test using a cone-shaped mold to see how well the mix holds its shape. There are four types of slump: true, shear, collapse, and zero. The type of slump determines the workability of the concrete and indicates how you need to alter the mix to use it.

True slump is the ideal type of slump to achieve when mixing concrete. True slump is when the concrete mix mostly retains the shape of the mold with a minimal and even amount of settling. This indicates that the mix is a workable consistency.

Shear slump is when the mix falls at a steep angle from one side of the molded shape. This can result from improperly mixed concrete or an imbalance of mix components and can result in instability of the poured concrete.

Collapse slump describes a mix that does not retain its shape at all and often results from a mix with too much water. If concrete with this type of slump is poured, it will be susceptible to cracks, shrinking, and reduced durability.

Concrete with zero slump exactly retains the shape of the mold without any settling at all. Zero slump concrete is unworkable and is usually due to too little water in the mix. A mix with zero slump will not pour, fill forms, or set correctly and should not be used.

Contractors use a class method to signify the slump consistency of concrete. In the simplest terms, the slump classes range between S1 and S5, with S1 being quite dry with a low slump and S5 having a high moisture content and high slump. Here are some common ways each concrete slump class is used in construction projects:

Mixing the right concrete and water ratio is a crucial first step. A too wet or too dry concrete mixture will result in cracking and structural failures over time. A masonry contractor will know the proper ratio for your specific project.

| Slump Class | Concrete Consistency | Concrete Uses |

|---|---|---|

| S1 | Rigid | Roads, Pipe beds, Curbs |

| S2 and S3 | Loose | Strip footings, Trench foundations, Flat slabs |

| S4 and S5 | Flowing | Sidewalks, Patios, Driveways |

Within each project, there may be options to use different slumps depending on your preferences. For example, when you hire a concrete contractor, they may charge different prices to install a patio depending on the texture and finish of your concrete.

A concrete slump test uses a cone-shaped tester mold, a piece of rebar or rod, and a measuring tape. Fill the mold a third of the way with the concrete mix and tamp it down with the rebar or rod so it fills the shape of the cone. Repeat this process twice until the cone is filled with the concrete mix.

Once the mold is filled, carefully remove the mold and let the concrete naturally slump. Measure the distance between the top of the concrete and the top of the mold. The number of inches between the two will determine the slump of the concrete.

While this is a relatively easy DIY test to perform, working with concrete and building crucial structures on your property should still be left to the professionals. If you're replacing your driveway, for example, call a local concrete company to take on the job.

Ginny Bartolone contributed to this piece.

From average costs to expert advice, get all the answers you need to get your job done.

Concrete driveways stand up to a lot of pressure over the years. How much do concrete driveway repairs cost when it's time to give it a little TLC?

Between the endless customizations and decades of strength, the cost of a concrete driveway may be worth the investment. Let's break down your bottom line.

Whether you’re planning on putting in a concrete driveway, patio, or staircase, use this concrete delivery cost guide to get an accurate estimate.

Did you know there are different types of pre-mixed concrete? Learn what project each type is best for, important terms, and more.

Looking for a durable and more affordable alternative to a concrete driveway? Learn about crushed concrete driveway costs and if it’s a good option.

Are you planning to pour a new concrete driveway? Keep tire track imprints off your new driveway by knowing how long before you can drive on concrete.