Discover the cost to replace asbestos siding, including key cost factors, and tips to help homeowners budget for safe and effective siding replacement.

Fiberglass is leaving asbestos in the dust

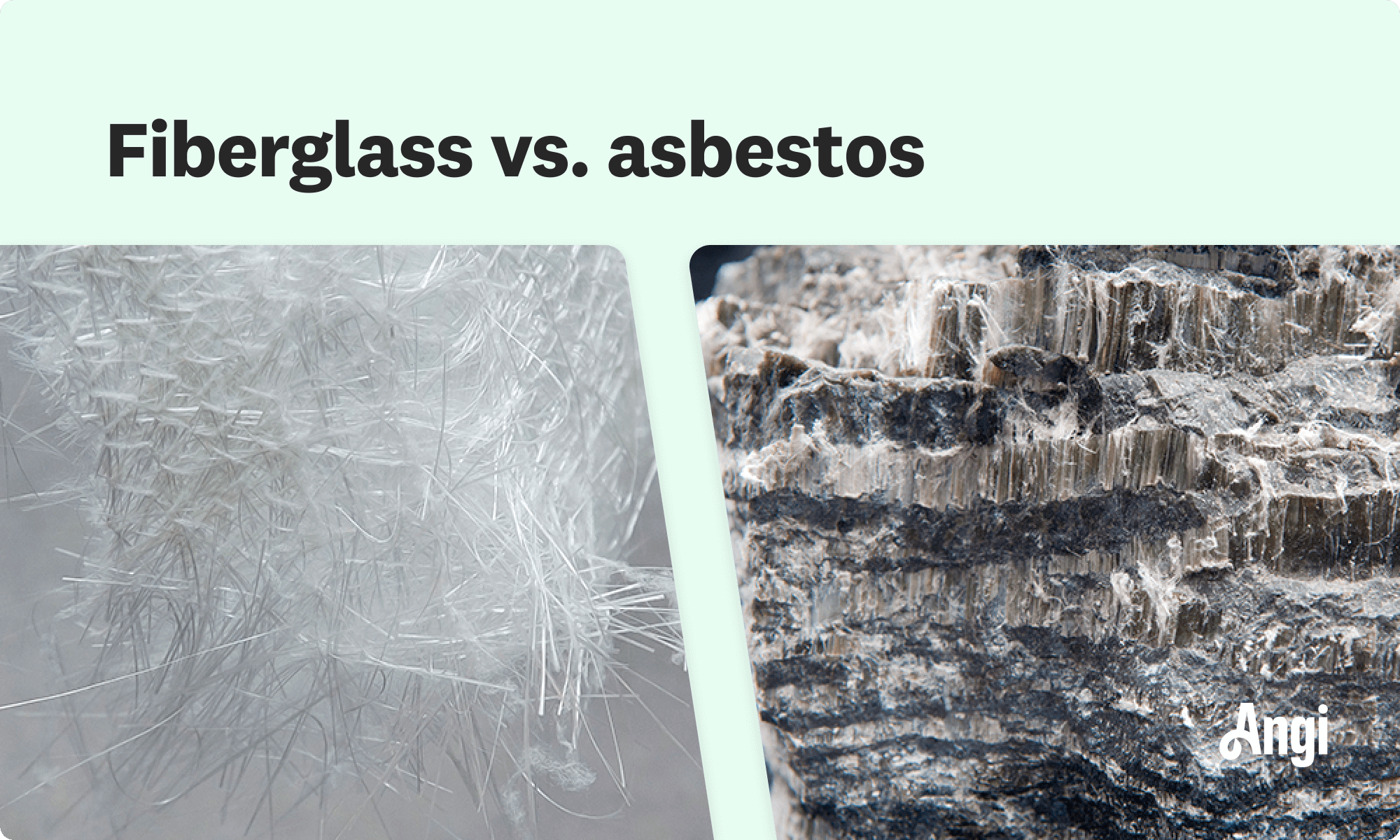

Both asbestos and fiberglass feature heat resistance and insulation properties.

Asbestos can cause significant health risks, especially following prolonged exposure.

Fiberglass has emerged as a human-made alternative to asbestos.

Asbestos and fiberglass have both been important in construction, but their differences in composition, health effects, and environmental impact have caused a significant shift in preferences. Asbestos, previously renowned for its ability to resist fire and insulate, is now subject to strict regulations and bans due to the dangers associated with its microscopic fibers. In contrast, fiberglass has become a safer alternative, with increased durability, versatility, and a smaller environmental footprint. Read on to compare asbestos vs. fiberglass to help you make informed choices in modern construction.

| Asbestos | Fiberglass |

|---|---|

| Naturally occurring mineral fibers | Synthetic fibers, typically made from glass |

| Severe health risks | Generally considered safe |

| Costly to remove | Cost-effective installation |

| Difficult to dispose | Environmentally-friendly |

| Requires careful handling | Easy to handle and install |

Many homeowners, especially in older homes, are curious to learn about asbestos. Asbestos is a naturally occurring mineral fiber that gained widespread industrial use due to its impressive properties such as heat resistance, durability, and insulation capabilities. Asbestos' ability to withstand heat and fire, coupled with its affordability, made it a preferred choice for insulation and fireproofing materials. There are six main types of asbestos, with chrysotile, amosite, and crocidolite being the most common. Its versatility led to it being used in a variety of industries, but construction is what it's typically associated with.

However, over time, the health hazards associated with asbestos exposure became increasingly evident. Inhalation of asbestos fibers over a prolonged period can result in severe respiratory illnesses like asbestosis, lung cancer, and mesothelioma. In response, many countries have implemented strict regulations and bans on asbestos use, leading to a decline in its industrial applications. There is now a renewed focus on asbestos removal and remediation efforts to address the environmental and public health concerns associated with past asbestos use.

Fiberglass is a composite material consisting of fine glass fibers embedded in a polymer matrix. Its popularity in the construction industry can be attributed to its versatile, strong, and durable properties. Fiberglass is frequently used for insulation, roofing, and reinforcement purposes. The material is non-corrosive, resistant to moisture, and lightweight, which makes it an excellent choice for both residential and commercial structures.

In construction, fiberglass-reinforced plastics (FRPs) are used to provide a strong and lightweight alternative to traditional components such as panels, pipes, and architectural features. The material also contributes to energy efficiency, regulating temperature and reducing the need for excessive heating or cooling. Fiberglass's resistance to rot, corrosion, and fire makes it a reliable and long-lasting option in the construction industry.

Fiberglass is often considered a replacement product for asbestos in certain applications due to its similar insulating characteristics, versatility, and reduced health concerns. It has emerged as a safer alternative in construction, especially when insulation and fireproofing are a concern.

While fiberglass and asbestos are used for similar purposes in construction, the materials are not quite the same.

Fiberglass is a human-made composite, while asbestos is a naturally occurring mineral with known health hazards. Fiberglass is a synthetic substance that consists of fine glass fibers containing silica, soda, lime, and alumina. These fibers are fused together using either an epoxy or polyester resin. Asbestos is a mineral that occurs naturally and has a crystalline structure. Chrysotile, amosite, and crocidolite are the most prevalent types of asbestos, which are identified by their thin, needle-like fibers.

Despite their fibrous nature, the structural arrangements of fiberglass and asbestos differ. Fiberglass consists of fine glass fibers that are arranged in a woven or matted pattern within a polymer matrix, resulting in a highly flexible and durable composite. Depending on their intended use, these fibers can be randomly oriented or organized in a specific pattern.

Asbestos possesses a crystalline structure characterized by long, thin fibers that appear needle-like. These fibers interlock to form a complex matrix, which accounts for its remarkable heat resistance and durability.

Asbestos has a long history of being used in building materials such as insulation, roofing, and fireproofing due to its insulating and fire-resistant qualities. However, because of the serious health risks linked to asbestos fibers, the construction industry has decreased its usage and implemented strict regulations for its removal. Instead, fiberglass has become a popular and safer alternative, offering outstanding thermal and acoustic insulation capabilities. Fiberglass is frequently used in insulation, roofing, and reinforced plastics, providing durability, moisture resistance, and lightweight construction without the harmful effects of asbestos.

Fiberglass is a cost-effective option due to its synthetic nature, making it easier to manufacture and install. Asbestos, once known for its durability, has become a more expensive option due to regulations and safety measures required for its use. The health risks associated with asbestos exposure have led to a decrease in its use, resulting in increased costs for compliance and remediation, and a shift towards safer alternatives such as fiberglass in industries like construction.

Another cost factor associated with asbestos is the removal of the material. Asbestos removal cost ranges between $1,192 and $3,240, and hiring an asbestos abatement professional is highly recommended to ensure safe removal.

Fiberglass is renowned for its impressive durability and its ability to withstand corrosion, rot, and moisture. This reliable material boasts a lengthy lifespan and is known for retaining its structural integrity over time, making it a preferred choice for construction applications.

Asbestos, while also durable, has seen a significant decrease in usage due to the serious health risks associated with its fibers. Despite exhibiting strong resistance to heat and fire, asbestos is overshadowed by concerns surrounding its longevity. The potential for asbestos-containing materials to become brittle or deteriorate poses a threat of fiber release into the air, which has driven the demand for safer alternatives such as fiberglass in construction and other industries.

The use of asbestos comes with major risks that can not only be harmful to people but to the environment as well, which is a stark difference compared with fiberglass.

Inhalation of asbestos fibers is known to cause severe health risks including lung cancer, asbestosis, and mesothelioma. This is in stark contrast to fiberglass which has minimal health impacts. While fiberglass exposure can result in skin irritation or respiratory discomfort, the potential for serious health complications is relatively low.

Because of the significant health risks associated with asbestos, there are stringent regulations in place to mitigate these dangers, including bans on its use and ongoing efforts to remove and remediate asbestos-containing materials. Overall, fiberglass is considered safe for construction applications, whereas asbestos remains a serious and well-documented concern.

Inhalation of microscopic fibers from asbestos has been found to cause severe respiratory diseases and cancers, hence the strict regulations and bans on its use to minimize exposure. Fiberglass is generally regarded as safe when handled properly, though fiberglass dangers can exist if proper care is not taken. Though it may cause some irritation when inhaled, the health risks are considerably milder compared to asbestos. Safety concerns with fiberglass primarily revolve around physical irritation to the skin and eyes during handling, rather than the life-threatening health issues associated with asbestos exposure.

Asbestos presents difficulties in both environmental durability and disposal, as its tough composition and slow breakdown can cause lasting ecological effects. Fiberglass, on the other hand, boasts a much lower environmental impact due to its recyclable nature and the use of recycled materials in modern products. Compared to asbestos, fiberglass is widely regarded as eco-friendly, and ongoing recycling efforts only serve to reduce its ecological footprint further. Strict disposal measures are necessary for asbestos to prevent environmental contamination, while fiberglass poses no such concerns.

Incredible workers! Very skilled with the machinery, climbing, cutting, roping, and removal. Handled everything. Professionals!

Our office has a new lease on life, thanks to Custom Paint Jobs LLC. Outstanding work!

Window Depot did an amazing job on my deck. I wasnt sure what I wanted to do, but their composite decking was affordable and will last a long time. I am excited to have family over, and I am no longer embarrassed by my backyard. Jeff and the ground crew were polite, respectful, and caring for...

Great experience all together. Dog friendly, courteous, great results and honest with recommendations. Will certainly be using Cardinal in the future for any carpet repairs

Jeff was a consummate professional. Responsive, courteous, and focused on meeting our needs. I had a small project of installing and replacing two ceiling light fixtures. He responded to my Home Advisory inquiry within 24 hours and in a span of two weeks our light fixtures were installed. ...

We used Unique Hardwood Floor LLC three years ago to work on the floors of a 70 year old home that needed a great deal of work. Some floors needed repairs, some were replaced and others just needed to be refinished. It was a complicated job as they needed to blend the old and the new to...

Our movers on November 25, 2020 were Lamar (#1897) and Dame (#1929), and they did a FABULOUS job. The guys were so helpful, accommodating and friendly. They worked diligently and got the job done in a very reasonable period of time. We were extremely impressed! This was our third or forth...

Lyle did a great job removing asbestos shingles from our front porch roof. They worked together with our roofer to make sure that the new roof was able to be installed on the same day that Lyle removed the asbestos shingles.

Involved an extensive bathroom remodel, including removing tub & installing walk in shower, new drywall, custome tile work to ceiling, plumbing, etc. Overall, job was done on time and on budget. Nick & his team were very professional and had high attention to detail. Quality was great. Highly...

Extremely well. Ohio Tree Care is my go to company for all tree care and snow removal services. they are professional, knowledgeable and affordable. I manage five camps in 33 counties and Ohio Tree Care has serviced every one of our properties. Highly recommend.

From average costs to expert advice, get all the answers you need to get your job done.

Discover the cost to replace asbestos siding, including key cost factors, and tips to help homeowners budget for safe and effective siding replacement.

Discover the cost to remove asbestos siding, including average prices, key cost factors, and tips to help homeowners plan a safe and budget-friendly project.

Asbestos removal costs vary based on where it’s located, the size of the job, and if there is any underlying damage. Learn what has the biggest effect on the cost.

If you need to cover asbestos tiles, you must do it safely. Learn why hiring a professional to carry out both inspection and work is the only recommended option.

Asbestos poses a major risk to members of your household. If it’s in your home, you'll want to know: how long does asbestos removal take? Here’s what to know.

In some circumstances, sealing asbestos may be the way to go, rather than removal. Read on to learn how to encapsulate asbestos pipe insulation.